Introduction — a market shift with engineering reasons

For decades, sealed lead-acid (SLA) batteries dominated stationary storage, backup power, and many industrial applications because they were inexpensive and well-understood. Today, however, Lithium Iron Phosphate (LiFePO4, LFP) chemistry is rapidly displacing lead-acid in a wide set of commercial and industrial uses. This transition is not just market hype — it’s rooted in measurable technical advantages (cycle life, usable depth of discharge, energy density, safety) and improving economics when evaluated on a total cost of ownership (TCO) basis.

This article explains the engineering differences that matter to procurement teams and OEMs, compares real performance metrics, and gives practical guidance for bulk buyers who are planning a migration from lead-acid to LiFePO4 packs.

Key technical differences (quick view)

Why the chemistry matters

- LiFePO4 uses iron and phosphate as the active cathode materials. The crystalline structure is intrinsically thermally stable and less prone to oxygen release under abuse, which improves safety.

- Lead-acid relies on lead dioxide / sponge lead reactions and an aqueous sulfuric acid electrolyte, which are mature but heavy and susceptible to sulfation and capacity loss under deep discharge or long float misuse.

Performance comparison (typical practical numbers)

The table below summarizes realistic expected values for typical industrial formats (nominal pack-level comparisons are approximate and depend on cell format, BMS, and thermal management).

| Metric | Typical Lead-Acid (VRLA) | Typical LiFePO4 (LFP) | Practical Impact for Buyers |

| Nominal voltage per cell | 2.0 V | 3.2–3.3 V | LFP needs fewer series cells for similar pack voltages |

| Usable Depth of Discharge (recommended) | 30–50% | 80–90% | LFP delivers 2×–3× usable energy per rated capacity |

| Cycle life (to ~80% capacity) | 300–500 cycles | 2,000–5,000 cycles | LFP greatly extends service interval and lifespan |

| Energy density (Wh/kg) | ~30–50 Wh/kg | ~90–160 Wh/kg | LFP is lighter — critical where space/weight matter |

| Charge acceptance / fast charge | Moderate | Good (with right BMS & thermal) | Faster recharge for LFP improves system responsiveness |

| Weight & volume | Heavy, bulky | Lighter, more compact | Reduced logistics and mounting costs |

| Maintenance | Often requires occasional maintenance (in some types) | Maintenance-free | Lowers operating labor and failure risk |

| Safety | Reasonable, but thermal runaway risk exists with misuse | Excellent thermal stability; lower runaway risk | Lower risk profile for installations near people |

Practical advantages that drive adoption

Lower lifecycle cost (TCO)

Although the initial purchase price per ampere-hour of LiFePO4 is typically higher than lead-acid, LFP’s far longer cycle life and deeper usable depth of discharge reduce replacement frequency and total field maintenance. For applications with frequent cycling (UPS, telecom backup, microgrid storage, electric mobility), lifecycle cost frequently favors LiFePO4.

Higher usable capacity and better space efficiency

Because LFP allows higher depth of discharge without accelerated degradation, the effective usable energy per rated amp-hour is substantially higher. This means a smaller LFP pack can often replace a larger lead-acid bank while delivering equal or better runtime.

Safety and environmental benefits

LiFePO4 chemistry is one of the safest lithium chemistries available: it is resistant to thermal runaway and performs reliably under higher temperatures and charging stress. Lead-acid batteries contain larger quantities of toxic lead and sulfuric acid and present recycling and handling challenges.

Operational reliability and lower maintenance

Industrial users appreciate that LFP systems are largely maintenance-free, need no water topping, and are less vulnerable to sulfation — the common failure mode for lead-acid under partial state-of-charge operation.

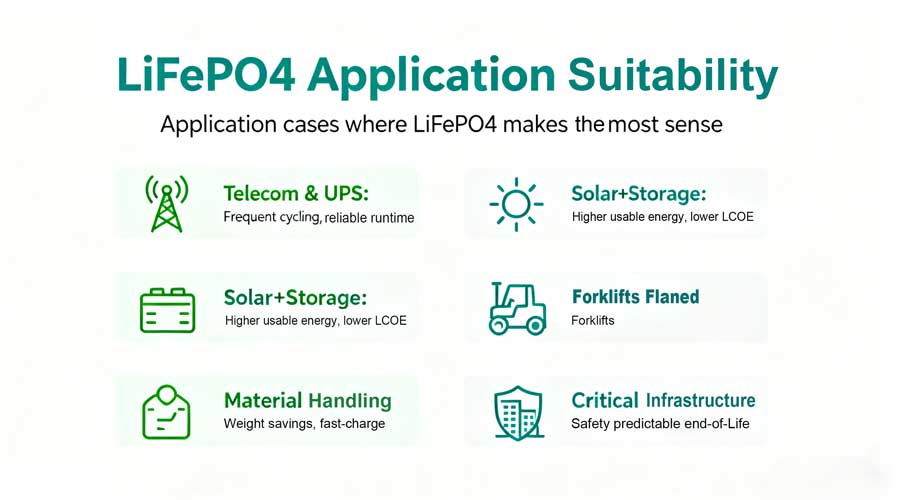

Application cases where LiFePO4 makes the most sense

- Telecom and UPS: Frequent charge/discharge cycling and requirements for dependable runtime favor LFP.

- Solar + storage (off-grid or hybrid): Higher usable energy and longer cycle life reduce system level LCOE.

- Material handling / motive power: Weight savings and fast-charge capability enable longer shift operation and quicker turnarounds.

- Backup power for critical infrastructure: Improved safety and predictable end-of-life behavior reduce operational risk.

For project planners, the rule of thumb is: the higher the cycle frequency and the longer the intended service window, the stronger the case for LiFePO4.

Procurement checklist for bulk buyers

When you are planning a mass purchase/upgrade from lead-acid to LiFePO4, require the following from suppliers:

- Cycle life and calendar life data: Ask for standardized cycle test reports (80% DoD or 1C equivalent) and calendar aging tests at typical operating temperatures.

- Depth of Discharge guidance: Request recommended DoD ranges for target cycle life and matching BMS cutoffs.

- Thermal management & operating temperature range: Confirm continuous charge/discharge limits and required cooling (if any).

- BMS features and protections: Cell balancing, over/under voltage protection, overcurrent protection, and cell-level monitoring.

- Certifications & safety tests: IEC, UN38.3, CE, RoHS as applicable for shipping and regulatory compliance.

- Sample validation: Insist on pre-production sample packs and field-trial runs under expected load profiles.

These items reduce integration risk and prevent costly in-field surprises.

How Himax Battery supports a seamless migration

Himax Battery offers end-to-end support tailored for B2B bulk procurement:

- Custom pack engineering — cell selection, cell balancing strategy, and mechanical design to match your rack or chassis constraints. (See: /custom-battery-design/)

- Product lines — standardized LiFePO4 modules and bespoke battery systems for telecom, solar storage, and motive power. (See: /lifepo4-battery/)

- Pre-production validation — sample packs, cycle testing, environmental stress screening, and reportable test data for RFQ qualification.

- After-sales & warranty — structured warranty terms with performance guarantees and field support.

By combining engineering validation with procurement support, Himax helps buyers realize the lifecycle benefits of LFP without introducing integration risk.

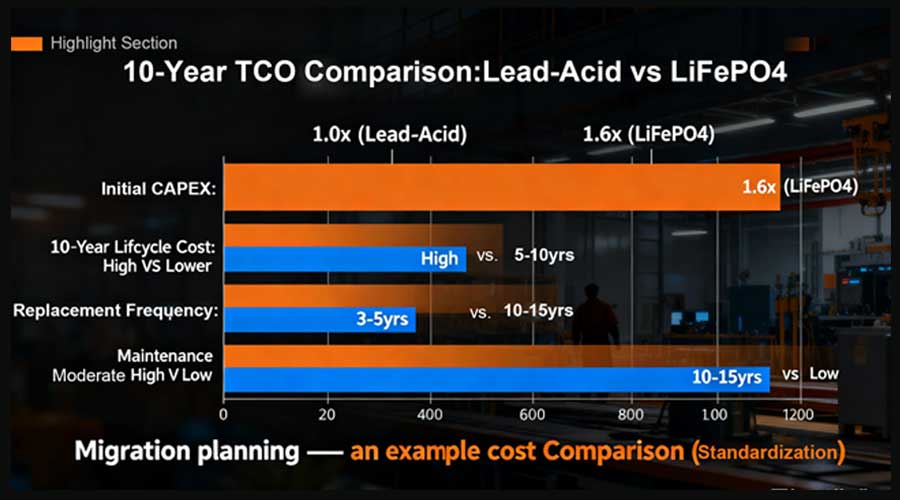

Migration planning — an example cost comparison (illustrative)

Below is a simplified illustrative comparison for a system that requires 10 kWh usable energy. Numbers are example estimates to show how TCO shifts.

| Item | Lead-Acid Bank | LiFePO4 Pack |

| Required nominal capacity (to get 10 kWh usable) | 20 kWh (50% DoD) | 11.5 kWh (87% DoD) |

| Pack mass (approx.) | 400 kg | 120 kg |

| Initial CAPEX (relative) | 1.0x | 1.6x |

| Replacement frequency (years) | 3–5 yrs | 10–15 yrs |

| Estimated 10-year lifecycle cost (incl. replacements) | High | Lower (despite higher CAPEX) |

| Maintenance labor & disposal issues | Moderate to high | Low |

Note: exact numbers vary by cell type, BMS complexity, and local labor/recycling costs. Ask Himax battery for a tailored TCO estimate based on your duty cycle.

Conclusion — engineering choices that shorten payback period

LiFePO4 is replacing lead-acid for valid technical and economic reasons: higher usable energy, dramatically longer cycle life, superior safety, and lower operational overhead. For buyers who evaluate systems by lifecycle cost and reliability, migrating to LiFePO4 often shortens payback and reduces total ownership headaches.

If you are planning a bulk purchase or fleet upgrade, Himax Battery can provide datasheets, sample packs, in-house cycle test reports, and design support to make the transition predictable and economically defensible.

Next steps & call to action

For a customized migration plan, TCO analysis, or sample request, contact Himax Battery:

- Product pages: /lifepo4-battery/ — /lithium-ion-battery/ — /custom-battery-design/

- Request a quote and sample validation: himaxbattery.com/contact