Deep discharge—draining a large portion (or all) of a battery’s stored energy before recharging—is a common operating condition across applications (solar, EV, tools, backup). This article quantifies what “deep” typically means, shows how depth-of-discharge (DoD) drives aging and usable life, describes safe recovery and BMS protections, and gives an actionable procurement checklist so engineers and buyers can specify battery packs that survive real-world use.

Data-first definition: what is “deep discharge”?

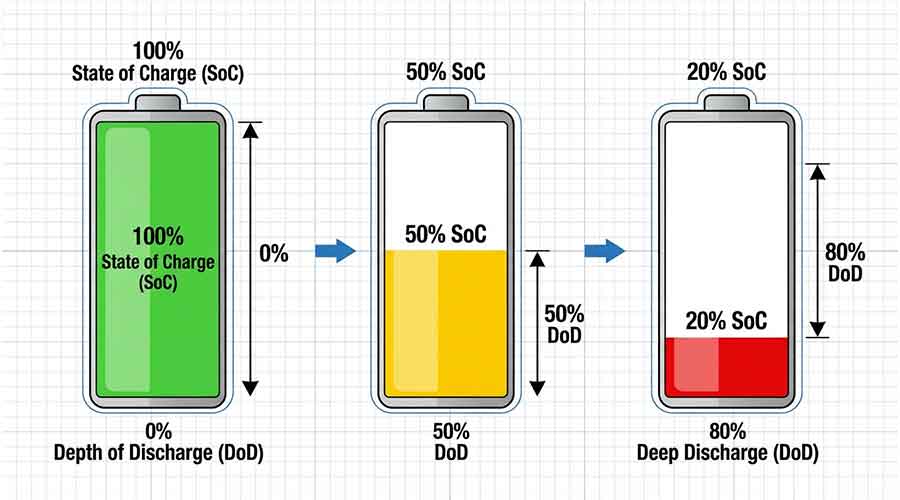

Deep discharge refers to removing a large fraction of a battery’s stored energy during a cycle. Practically, the industry often treats discharges beyond ~50–80% DoD as “deep,” depending on chemistry and application. For test and cycle-life reporting, manufacturers frequently use 80% DoD as a standard baseline.

Key metric reminder:

- DoD (%) = (Energy removed ÷ Total nominal energy) × 100

- Usable energy (Wh) = nominal voltage (V) × Ah rating

How DoD affects cycle life: the numbers (quantitative)

The general relationship (rule-of-thumb)

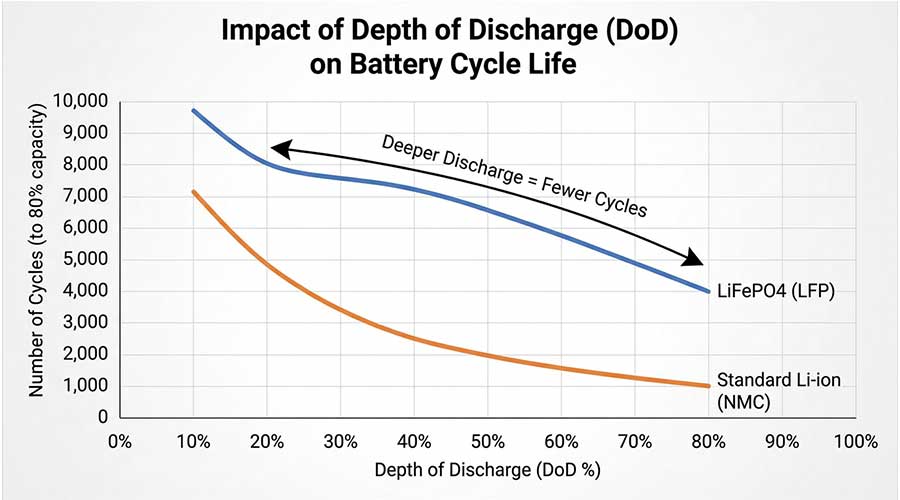

Multiple empirical studies and historical testing show an inverse relationship between DoD and cycle life: as DoD increases, cycles to end-of-life drop. A classical engineering heuristic is that reducing DoD by ~20 percentage points can approximately double cycle life under similar conditions—though exact slopes depend on chemistry, C-rate, temperature, and cell design.

Practical cycle estimates (typical ranges)

Below is a practical, industry-used reference table for LiFePO4 (LFP) and generic lithium-ion cells. These are approximate ranges (real-world results depend on test protocol and temperature):

| Chemistry | Typical DoD used in spec | Typical cycles to ~80% capacity (order of magnitude) |

| LiFePO4 (LFP) | 80% DoD (common spec) | ~3,000–8,000 cycles. Higher cycle counts (4k–8k) are achievable with quality cells and moderate C-rates. |

| Li-ion (NMC / high energy) | 80% DoD (typical spec) | ~1,000–3,000 cycles (varies widely with formulation and temp). |

Example calculation: a LiFePO4 pack rated 100 Ah at 12.8 V = 1,280 Wh. If manufacturer rates 4,000 cycles at 80% DoD, that implies ~4,000 × (1,024 Wh usable per cycle) ≈ 4.1 MWh delivered over life (ignoring calendar aging).

Evidence & nuance: controlled lab experiments and recent studies confirm these ranges and show DoD is a dominant variable, but not the only one—C-rate, temperature, and SOC window also strongly influence results.

Why deep discharge damages some chemistries more than others

Lead-acid vs LiFePO4 vs NMC (high-level)

- Lead-acid: deep discharges (high DoD) accelerate sulfation and drastically reduce cycle life. Keeping DoD shallow (≤50%) is common for long life.

- LiFePO4 (LFP): structurally robust; can tolerate deeper DoD repeatedly while retaining long cycle life, which is why LFP is favored in stationary storage. Still, shallower cycling increases lifetime.

- NMC / high-energy Li-ion: more energy-dense but usually more sensitive to deep cycling at high temperatures and high C-rates.

Recovery from deep discharge: safe procedures & limits

When recovery is feasible

- If a battery reached a very low terminal voltage but cells are not internally shorted or severely chemically damaged, limited recovery may work. Some manufacturers provide stepwise recovery procedures (e.g., controlled pre-charge, parallel-to-healthy-battery conditioning). These procedures must be executed with monitoring and PPE.

Recovery workflow (engineer checklist)

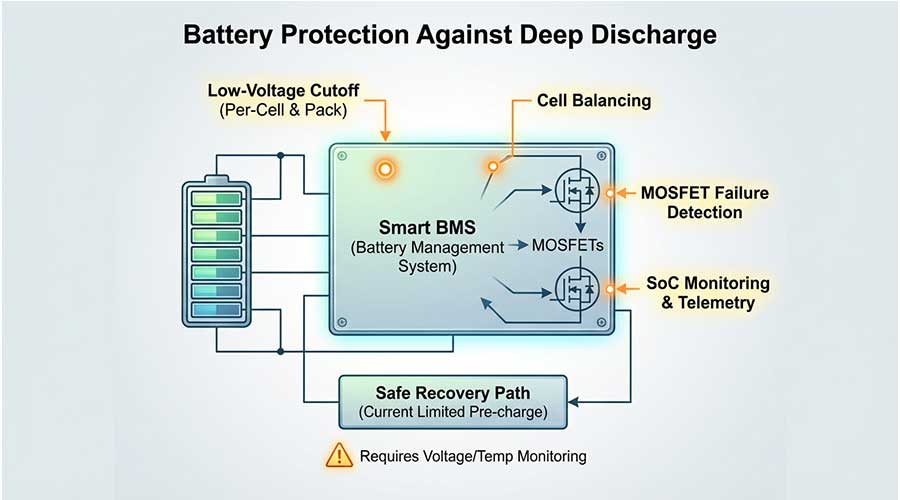

- Isolate the pack and follow manufacturer guidance—do not connect untrained equipment.

2. Measure per-cell voltages; if any cell < manufacturer minimum (often ~2.5–3.0 V for Li-ion), inspect individually.

3. If safe, apply a limited-current pre-charge to raise each cell to a safe threshold (~3.0 V for many Li-ion ICs) before normal charge. Use current-limited lab PSU or charger with recovery mode.

4. Monitor temperature and voltage continuously. Stop immediately on abnormal heating or large cell imbalance.

5. Run capacity and internal resistance tests after recovery — often the pack will have permanently reduced capacity or higher internal resistance.

Important: deep-discharge recovery can work for some packs but not for packs with internal shorts, severe degradation, or long-term self-discharge below safe thresholds. Rely on manufacturer repair/replacement policies when available.

Prevention: engineering controls that limit deep discharge risk

BMS & protection features (what to require)

To prevent harmful deep discharge and to support recovery when necessary, a modern BMS should include:

- Low-voltage cutoff per-cell and pack-level to prevent over-discharge.

- Cell balancing to avoid one weak cell being driven into deep discharge.

- MOSFET status / failure detection and event logging so that switch failures or shorts are diagnosed early.

- State-of-charge (SoC) estimation and configurable DoD limits for different modes (normal, long-term storage).

- These protections materially reduce field failures and simplify warranty and maintenance management.

Operational policies

- Define an operational DoD target for the product (example: 20–80% SOC window) that balances runtime and lifecycle cost.

- Enable “reserve” mode in firmware that keeps a buffer (e.g., 5–10%) to prevent inadvertent deep discharge in edge cases.

- Include telemetry (CAN/Bluetooth) for fleet monitoring to detect recurring deep-discharge events early.

Procurement & RFP checklist: specify DoD & protections explicitly

When you request quotes or compare suppliers, insist on these items in the spec:

Electrical & lifecycle

- Rated nominal voltage and usable Wh at specified DoD (e.g., usable Wh at 80% DoD).

- Cycle-life curve or table vs DoD (e.g., cycles to 80% capacity at 100%/80%/50% DoD).

BMS & diagnostics

- Per-cell low-voltage cutoffs and balancing accuracy.

- MOSFET failure detection, event logging, and communication interface (CAN/RS485/Bluetooth).

Testing & compliance

- Deliver sample test reports (cycle test protocol, temperature conditions).

- Required certifications (e.g., UN38.3 for transport, IEC standards where relevant).

After-sales

·Recovery / repair policy for deeply discharged packs (procedure, authorized returns).

·Local support or partner network for troubleshooting.

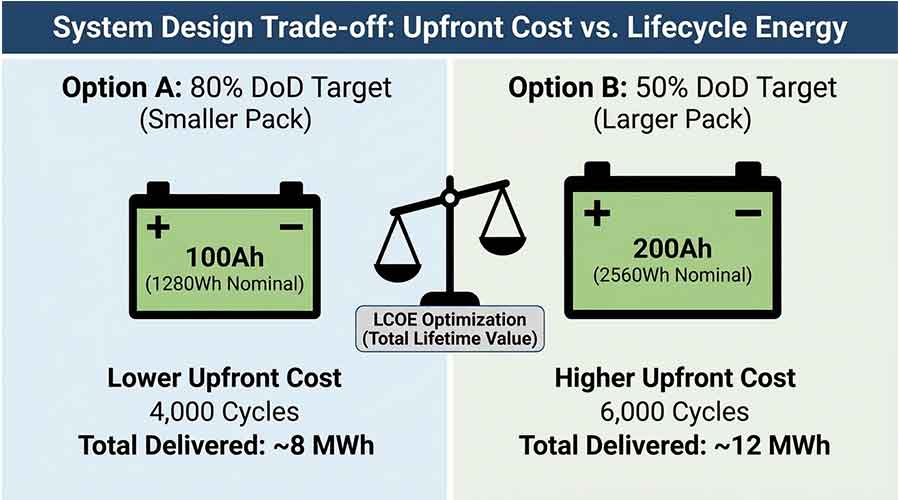

Quantified example: design trade-offs for a solar backup system

Scenario: you need ~2 kWh usable energy daily for a remote site for 10 years with one cycle/day.

Options based on chemistry & DoD policy:

- LiFePO4, 80% DoD, 4,000 cycles:

o Usable per cycle = 2 kWh → total life energy = 2 kWh × 4,000 = 8 MWh.

o Calendar estimate: 4,000 cycles at 1/day ≈ 11 years (ignores calendar aging).

- LiFePO4, 50% DoD, 6,000 cycles:

o Pack must be larger (to deliver 2 kWh usable at 50% DoD, nominal capacity = 4 kWh).

o Total life energy = 2 kWh × 6,000 = 12 MWh — higher lifecycle delivered energy, but higher upfront cost.

Use LCOE-style calculation (cost per MWh delivered over life) to choose the optimal capacity vs. DoD target.

Industry trends & practical implications (data points)

- LFP adoption for stationary storage: LFP’s tolerance for deeper cycles and long calendar life is a major driver for grid and residential storage adoption. Expect vendors to quote cycle-life at 80% DoD as standard.

- Smarter BMS telemetry is increasingly normative; fleet/asset owners expect remote SoC/DoD monitoring and event logs.

How Himax Battery supports DoD-driven engineering (brief, practical)

Himax offers engineering support that helps customers translate DoD objectives into pack specs:

- Delivery of cycle-life data at requested DoD values and C-rates for chosen cell families.

- Custom BMS options with per-cell monitoring, MOSFET diagnostics, and configurable DoD/SOC windows.

- Recovery guidance and sample testing for packs to validate field tolerance to deep-discharge events.

When you ask multiple vendors for quotes, include a line-item asking them to provide cycles vs DoD at your target C-rate and operating temperature—this yields apples-to-apples comparisons.

Quick reference: best practices checklist (copy/paste)

- Target operational DoD (e.g., 50% / 80%): ______

- Required usable Wh per cycle: ______

- Required cycles to 80% capacity: ______

- BMS features required: low-voltage cutoff, balancing, MOSFET diagnostics, telemetry

- Recovery policy / authorized service centers: ______

- Certifications required: UN38.3 / IEC / other: ______

Conclusion (data-led takeaway)

Depth-of-discharge is among the most influential levers for battery lifecycle and delivered energy. Quantify your DoD target early, demand vendor cycle-life curves at that DoD and C-rate, and require BMS protections (low-voltage cutoff, balancing, MOSFET diagnostics, telemetry). With the right specs and supplier testing data, you can optimize lifecycle cost and operational resilience—especially when selecting LiFePO4 for heavy-cycle stationary applications.

Find articles related to Battery Pack