Understanding volts and amps is essential when you design, specify, or buy batteries. This guide uses plain English, concrete examples, and an actionable procurement checklist so engineers and B2B buyers can pick the right battery architecture for a real product or system.

Quick summary: the essentials

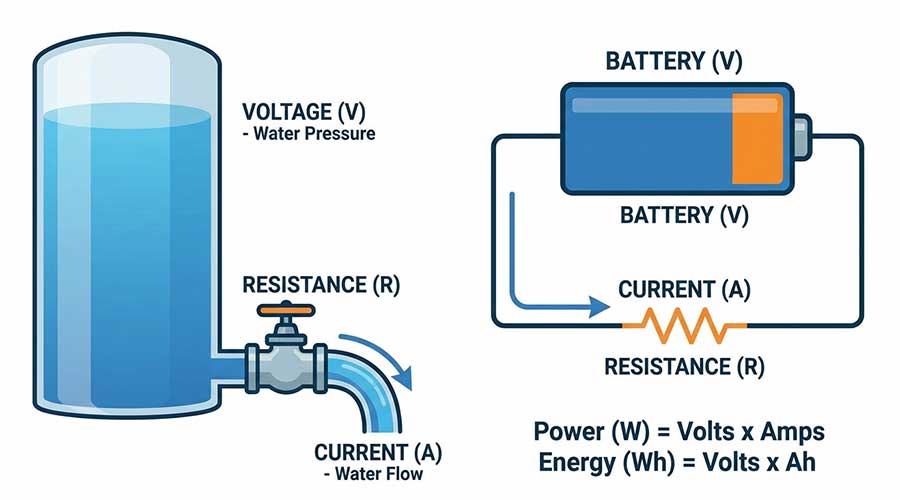

- Voltage (V) — electrical potential (like water pressure).

- Current (A / amps) — the flow of electric charge (like water flow).

- Power (W) = volts × amps — the rate of doing electrical work.

- Remember: energy stored = Wh = V × Ah. Use Wh (not Ah alone) to compare runtime across different voltages.

What voltage tells you (and why it matters)

Voltage in battery packs

- A single LiFePO4 cell nominal ≈ 3.2 V. Packs in series add voltages (4S → ~12.8 V).

- System voltage determines what power electronics you can connect directly and affects wiring size and efficiency.

When to choose higher voltage

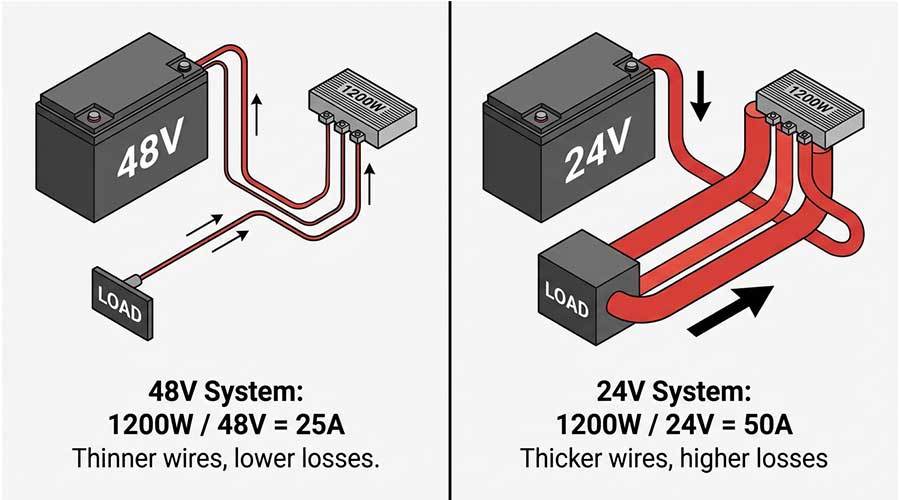

- For the same power, higher voltage reduces current (I), lowering I²R losses and allowing thinner wiring.

- Tradeoffs: higher-voltage systems need components rated for that voltage and stricter insulation and safety design.

Example: To deliver 1,200 W:

- At 48 V → I = 1200 / 48 = 25 A.

- At 24 V → I = 1200 / 24 = 50 A.

- Higher voltage halves current and roughly quarters resistive losses for the same wiring.

What current (amps) tells you (and why it matters)

Current defines stress and sizing

- Devices draw current: motors, inrush loads, and heaters can require large peak currents; sensors draw milliamps.

- Battery current determines thermal load, required cell C-rate, fuse sizing, and connector selection.

Important current specs

- Continuous discharge current — safe long-term draw.

- Peak (burst) current — startup or short pulses.

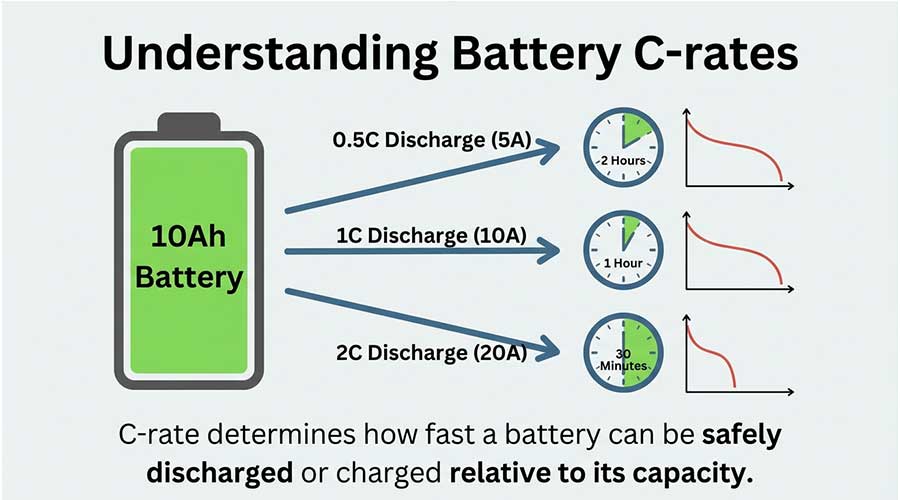

- Max charge current — how fast the pack can be safely recharged (often specified as a C-rate, e.g., 0.5C, 1C).

C-rate example: 10 Ah pack at 2C → 20 A discharge.

How volts & amps interact (practical formulas)

- Ohm’s law: V = I × R (R = resistance).

- Power: P = V × I.

- Energy: Wh = V × Ah.

Use these to size wires, fuses, and power electronics and to estimate battery heating and efficiency.

Battery performance under load: sag, heat, and aging

- Internal resistance (Rint) causes terminal voltage drop under load: V_terminal = V_nominal − I × Rint. High currents → larger voltage sag.

- Heat is proportional to I²Rint — high current accelerates thermal stress and capacity fade.

- Choose low-Rint cells for high-discharge applications (power tools, e-bikes).

Charging basics: voltage sets chemistry limits; current sets speed

- Voltage profile: each chemistry has a max cell charge voltage—exceeding it damages the cell.

- Charge current: higher amps = faster charge but more heat and stress. Smart charge algorithms taper current as voltage approaches the maximum to protect cells.

Rule of thumb: never exceed the manufacturer’s max charge voltage or recommended charge current without explicit validation.

Applications: how volts & amps change design choices

Consumer electronics

Low voltage, modest current — priority: energy density and compact size.

E-bikes & power tools

Moderate voltage + high discharge current — priority: low internal resistance cells and thermal management.

Solar ESS & backup power

Higher nominal voltages (24 V, 48 V, 51.2 V, 102.4 V, etc.) to improve efficiency in medium/high power systems; choose chemistries like LiFePO4 for long cycle life and stability.

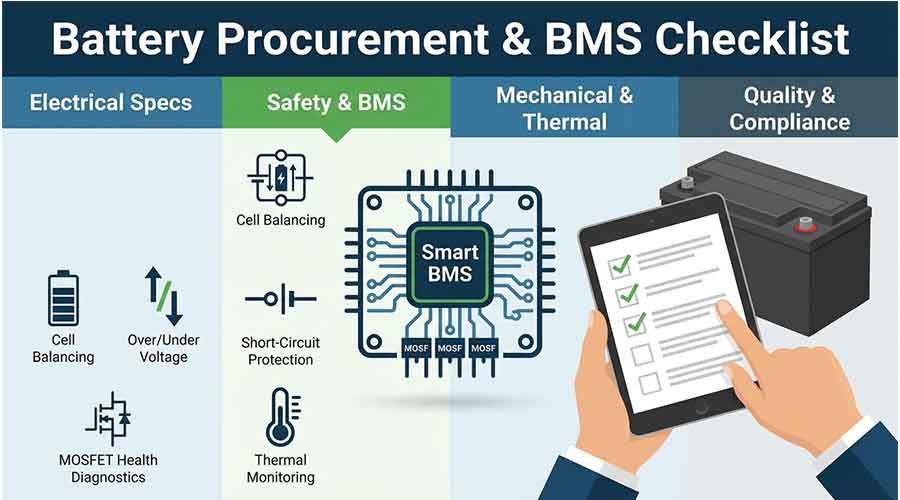

Procurement checklist — what to require from suppliers

Use this when requesting quotes or comparing vendors.

Electrical & performance

- Nominal voltage and max charge voltage (V)

- Continuous discharge current (A) and peak current (A)

- Rated capacity (Ah) and usable energy (Wh at specified DoD)

- Recommended max charge current (A) / C-rate

Safety & BMS

- BMS functions: cell balancing, over/under voltage, overcurrent, short-circuit protection, temp monitoring

- Diagnostic features: MOSFET health detection, event logs, communication (CAN/RS485/Bluetooth)

- Protections that matter for industrial buyers: MOSFET failure sensing, thermal cutoffs

Mechanical & thermal

- Enclosure rating (IP), connectors, terminal type, cooling strategy

Quality & compliance

- Test reports (cycle life, abuse tests), factory QA process, certifications required by market (e.g., UN38.3, IEC, CE)

- Samples, burn-in/run-in test options, and inspection rights for bulk orders

Logistics & after-sales

- Lead time, MOQ, spare modules availability, local after-sales support

Quick supplier-ready spec table (copy into RFP)

| Field | Example / Fill |

| System nominal voltage (V) | 12.8 / 25.6 / 51.2 |

| Continuous discharge (A) | e.g., 50 A |

| Peak discharge (A) | e.g., 200 A (10s) |

| Capacity (Ah) / Usable Wh | e.g., 100 Ah / 1280 Wh (80% DoD) |

| Max charge current (A) | e.g., 0.5C = 50 A |

| BMS features required | Balancing, MOSFET diagnostics, CAN |

| Certifications | UN38.3, IEC62619, CE |

| Notes | Thermal management, connector type |

Industry trends that influence volts & amps decisions

- Upward shift in system voltages for EVs and energy storage to reduce current and losses.

- Smarter BMS and diagnostics are standard for industrial packs (predictive maintenance, MOSFET monitoring).

- Preference for LiFePO4 in commercial storage for cycle life and safety—while high-power Li-ion variants remain common in high C-rate applications.

How Himax Battery can help (practical engineering support)

- Custom series/parallel layouts to meet target voltage and current requirements.

- Cell selection and testing for required C-rate and temperature ranges.

- Integrated BMS options with MOSFET failure sensing and diagnostics to reduce electrical risk.

- Sample testing, compliance documentation, and scalable production for bulk buyers.

Use these as checklist items in an RFP to compare vendors by engineering capability — not marketing.

Quick formulas & reference

- Power: P (W) = V (V) × I (A)

- Energy: Wh = V × Ah

- Example: 12.8 V × 20 Ah = 256 Wh

- C-rate: Current (A) = C-rate × Ah

Short FAQ

Q: Does higher voltage always improve efficiency?

A: Higher voltage reduces current for the same power, improving conductor efficiency, but requires higher-voltage-rated components and safety measures.

Q: Will a higher-amp charger force more current into my battery?

A: The battery/BMS limits charging current. A higher-rated charger only supplies capability; the pack draws what it safely accepts.

Q: What determines runtime most directly — V or Ah?

A: Runtime is determined by energy (Wh). Ah must be considered with system voltage: Wh = V × Ah.

Conclusion

Volts are pressure; amps are flow — together they define your system’s power and integration needs. For reliable performance, convert system power requirements into explicit voltage and current specs, require BMS diagnostics and MOSFET health features, and compare vendors with the same test and documentation standards.

Find articles related to Battery Pack