Smart glasses are no longer a prop from sci-fi — they’re a real product family with two overlapping but distinct goals: AI-first glasses, which put smart assistants and sensing front-and-center, and AR glasses, which blend graphics into your field of view. The hardware (cameras, mics, tiny processors) looks similar, but the design tradeoffs — especially battery, weight, and thermal management — are very different. This article breaks down the difference in plain English and explains how smart battery choices change the experience.

AI Smart Glasses: the “assistant” in your frames

AI smart glasses prioritize sensing, voice, and on-device (or cloud-assisted) intelligence. Typical jobs include voice queries, live transcription, visual search, object recognition, and hands-free photo/video capture. Because many AI tasks can be optimized for lower-power sensors or offloaded to the cloud, manufacturers often design these devices to be sleek and lightweight, with modest display needs and longer usable hours between charges.

Common hardware tradeoffs

- Tiny cameras + mics and a low-power AI pipeline (on-device edge inference + selective cloud offload).

- Minimal or no transparent display hardware (saves space and battery).

AR Smart Glasses: digital overlays that must be shown

AR smart glasses put visual overlays — navigation arrows, instructions, or 3D models — into your real world. That requires display tech (waveguides, micro-OLED, or HUD), accurate spatial tracking, and more graphics horsepower. The result: bulkier optics, higher power draw, and a much tougher battery envelope.

Key implications

- Displays + tracking = higher continuous power draw.

- Bigger batteries or swappable cases are common to maintain useful runtime.

- Tradeoffs: visual fidelity vs. comfort (weight and heat).

Quick comparison: what each type prioritizes

- Typical battery strategy: AI favors efficient cells + edge inference; AR requires higher-capacity cells and clever thermal design.

- Weight vs runtime: AR designers accept more weight (or external batteries) for better visuals; AI designers optimize for minimal mass.

Why battery chemistry & form factor matter more than you think

For wearables, energy density and form factor are the two biggest constraints. Lithium-ion and lithium-polymer (LiPo/pouch) chemistries deliver the best energy-per-gram available for commercial products today, which is why nearly all smart glasses use some flavor of Li-ion/LiPo. Li-Po (pouch) cells are especially attractive because they can be shaped thin and curved to fit temple or rim cavities. These chemistry choices underpin how long the glasses run, how warm they get, and how heavy the frame feels.

Design notes backed by industry guidance

- Li-ion/Li-Po offer the highest energy density currently available for compact wearables; this is why manufacturers pick them for smart glasses.

- Designers often must trade capacity for comfort: more mAh = more runtime but also more mass in the temples.

- For AR devices with persistent displays, total system power budgets can require external or swappable battery solutions to reach day-long use. Recent product examples show removable battery systems becoming more common in the space.

Practical battery specs for smart-glass engineers

Below are pragmatic targets to guide early development (these are starting points — real product needs vary):

- Ultra-light AI glasses (all-day wear): 200–400 mAh pouch cell(s); system draw optimized < 200–300 mW average.

- Hybrid AI + HUD (light AR): 400–800 mAh distributed cells (temples + bridge); expect display bursts that raise peak draw.

- Full AR (wide FOV waveguide): 800 mAh+ or swappable case solution; thermal pathways and active power management are essential.

For exact cell type, capacity, and pack topology you’ll select cells by required continuous and peak discharge (C-rate), physical envelope, and safety targets. See Battery University for chemistries and energy-density tradeoffs.

Thermal, charging, and safety considerations

- Thermal: Heat affects both user comfort and battery lifetime; place cells away from skin when possible and design airflow or thermal paths.

- Charging & case design: Many vendors offload charging to a companion case (like many true-wireless earbuds) to keep glasses light. Fast charging is possible but needs careful thermal control.

- Safety & certifications: For commercial wearable products, expect to meet regional safety standards (CE, RoHS, UN38.3, IEC norms). Certified packs prevent recalls and simplify distribution.

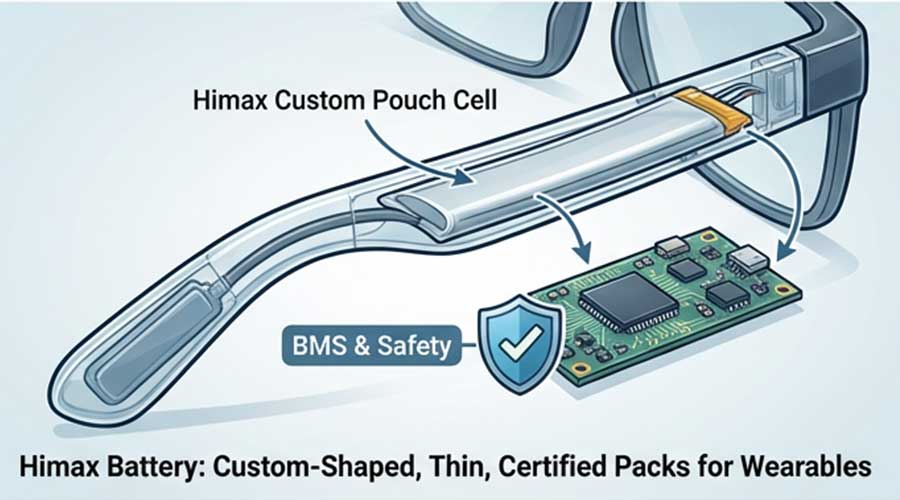

How Himax Battery helps designers ship better smart glasses

At Himax Battery we specialize in wearable and custom-shaped battery packs optimized for weight-sensitive products like smart glasses. Here’s how we make a difference for engineering and product teams:

- Form-fit pouch and custom cell shaping: We design ultra-thin, curved pouch cells and modular packs that tuck into temple arms or bridge zones — getting energy where space exists without forcing bulky frames.

- Chemistry choice tailored to the product: For the lightest AI glasses we recommend high-energy pouch Li-ion/Li-Po cells; for use cases needing extreme safety or long cycle life (some enterprise AR), we can design LiFePO4 variants where volume allows. (We’ll help you pick the right chemistry based on runtime, weight, and cycle-life targets.)

- Integrated BMS & safety layers: Our packs include BMS options for cell balancing, overcharge/overdischarge protection, and MOSFET-level fault detection — essential for always-worn devices.

- Prototyping, testing & certifications: We provide pre-sales QC, sample packs, and can support UN38.3, CE, and RoHS processes so your supply chain clears regulatory gates faster.

- Experience & support: With nearly two decades (18+ years) in battery manufacturing and custom solutions, Himax provides design consults, EMC-aware layouts, and after-sales technical support to help you iterate quickly and ship safely.

Want a sample? We offer engineering samples and design support so your team can validate fit, thermal behavior, and runtime before committing to mass production.

Quick checklist for smart-glass product managers

- Set an early target for acceptable weight (e.g., ≤40–50 g total device for consumer wear).

- Budget power into the UX: displays + tracking cost watts; microphones and event cameras cost milliwatts.

- Decide charging strategy: on-device charging vs. charged carry case vs. swappable battery.

- Specify required certifications and duty cycles up front (enterprise devices often need higher cycle life and extended warranty).

- Talk to your battery partner early — battery shape dictates mechanical design as much as electronics do.

Conclusion: the future is hybrid

The line between AI and AR glasses will keep blurring. The winners will be devices that pair smart, low-power AI with the right display compromises — and, crucially, the right battery strategy. When your team needs to balance runtime, weight, safety, and manufacturability, a battery partner that understands wearable constraints makes the difference between a prototype and a product people actually wear.

Himax Battery builds thin, certified, customizable packs for wearables and enterprise AR — from consultation and samples to production and after-sales support. Contact our wearable team at services@himaxelectronics.com to start a battery design review.

Find articles related to LiPo/pouch Battery