If you love flashlights, you already know the battery matters as much as the LED and driver. I’m Alex from Himax Battery — we design and manufacture rechargeable cells and packs — and I want to share a practical, user-friendly guide about flashlight batteries. This one’s written for hobbyists, EDC fans, and small manufacturers alike: quick trade-offs, safety reminders, and a few factory-side tips that aren’t obvious when you’re shopping by “mAh” alone.

This post is not marketing. It’s real-world advice from people who test cells and build packs every day.

The short version (TL;DR)

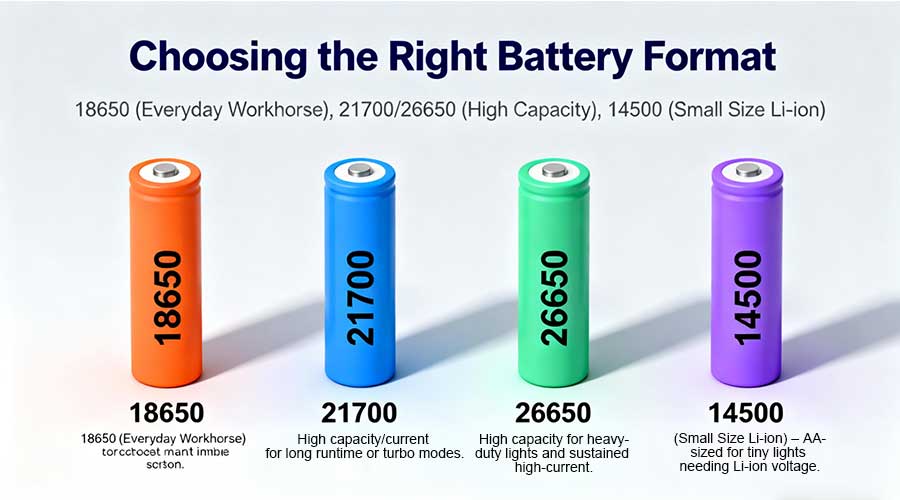

- 18650 = versatile, great balance of capacity and current.

- 21700 / 26650 = higher capacity and/or current for big throwers or long runtime.

- 14500 = AA-sized Li-ion for tiny lights that need Li-ion voltage.

- Protected cells are safer for casual users; unprotected are common in high-drain builds — make sure the light has proper cutoffs.

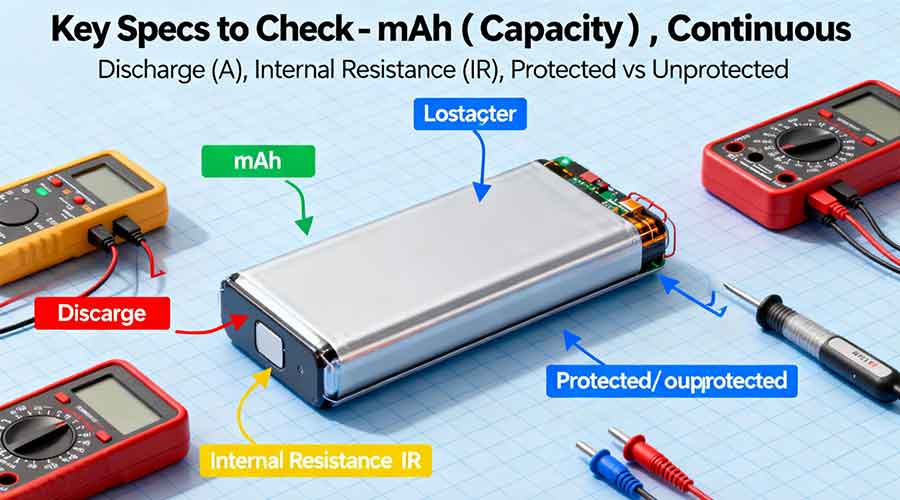

- Don’t pick cells by mAh only. Check continuous discharge rating (A), internal resistance (IR), and real-world sag under load.

- Use a good charger. On-board USB charging is convenient but not always gentle on cells long-term. External, balanced chargers are still best.

Cell formats & when to choose them

18650 — the everyday workhorse

Most full-size EDCs and mid-size flashlights are built around 18650s. They strike a good balance: decent capacity, multiple chemistry choices, and widely available. Use 18650s when you want predictable runtime and a wide selection of cells tuned for low IR or higher capacity depending on the light.

21700 / 26650 — when runtime or sustained high-current matters

For higher-output lights or heavy-duty work lights, 21700s and 26650s give longer runtime and often better thermal performance. If your driver needs sustained current for turbo modes, these formats can win even if the mAh numbers look similar.

14500 — small size, Li-ion punch

If your light is built for AA/14500 and you want Li-ion performance, 14500 is a good option. Do not swap 14500 into a light designed for NiMH AAs unless you confirm the charger and protection scheme are compatible.

Multiple cells & pack configurations

If a light uses multiple series cells (2×18650, 3×18650, etc.), matching is important. Use cells from the same batch with similar cycle history — mixing old & new, or high-IR with low-IR, increases stress and shortens life.

Key specs you must check (and what they mean)

- mAh (capacity): how much charge is stored — useful, but not the whole story.

- Continuous discharge rating (A): critical for high-output lights. This tells you what the cell can sustain without overheating or losing too much voltage.

- Peak discharge rating: often advertised for brief bursts; don’t assume sustained performance.

- Internal resistance (IR): lower IR → less voltage sag under load and cooler operation. For throwers and turbo modes, aim for low IR.

- Cycle life / chemistry: some chemistries (e.g., LiFePO4) trade capacity for safety and cycle life — useful in certain applications but less common in standard EDC lights.

·Protected vs unprotected: Protected cells include a small PCB to prevent over-discharge / over-current. Good for general users; less common in high-drain performance builds.

Charging: what most people miss

- External smart chargers (dedicated analyzers/chargers) offer balancing, proper termination, and cell-level health data. For long term battery health, they’re the best option.

- On-board USB charging is convenient but depends entirely on the light’s charging circuit. Some integrated chargers lack balance charging or accurate cutoff and can accelerate wear if you use them constantly. If a light has USB charging and you also care about lifespan, consider periodic charge cycles on an external charger.

- Avoid cheap, no-name USB chargers and inexpensive multi-port chargers without per-slot monitoring. They can overheat cells or leave them at 100% for hours.

Safety & storage — real, practical rules

- If a cell puffs/swells — stop using it. Do not charge, do not puncture. Move it outside if you can safely remove it, and store it in a metal container with sand or a LiPo safety bag until you can recycle it properly.

- Store spare cells at ~30–50% SoC for long-term storage. Full charge + heat = accelerated aging.

- Do not mix cell ages/brands in multi-cell packs. For packs, pair cells by capacity, IR, and cycle history. For bulk procurement, request matched batches.

- Use proper protection on packs destined for consumer products — BMS or protection PCBs that handle overvoltage, overcurrent, and temperature cutoffs.

Real-world testing — what matters more than paper specs

We run cells through discharge curves, thermal cycling, and IR tests. Two practical markers you can use when choosing cells:

- Voltage sag under realistic load. A cell that holds voltage under high current feels “punchier” and keeps output steady in turbo modes.

2. Heat rise during sustained draw. Lower temperature rise = more reliable and safer operation.

If a cell advertises very high mAh but sags heavily under load or gets hot, you’ll lose real-world performance in flashlights.

Buying tips for hobbyists and small brands

- Buy from reputable sellers. Avoid random “10000 mAh 18650” listings on marketplace sites. If a spec looks unbelievable, it probably is.

- Ask for datasheets. A genuine manufacturer provides IR, discharge curves, and cycle life data.

- Request batch traceability for bulk orders. For small-run OEMs, ask suppliers for batch IDs and QC reports.

- Consider certifications (UL/IEC/etc.) if your product will be sold commercially — they reduce liability and simplify shipping.

For OEMs & bulk buyers — what we recommend

If you’re sourcing batteries for a product or production run, here are some factory-side suggestions:

- Specify real-world discharge profiles when requesting samples. Don’t just request “max mAh” — provide the driver current profile you expect in the field.

- Require matched sets for multi-cell packs. Matching by capacity and IR avoids premature failure.

- Ask for QC & test reports (IR distribution, capacity spread, cycle test results).

- Clarify shipping & hazmat logistics. Damaged goods and hazmat rules can delay shipments — build realistic lead times for batteries.

- Certifications matter. For many markets, IEC/UL/CE and UN38.3 testing are basic requirements; getting them up-front saves headaches.

(Himax Battery provides spec sheets, matched-batch options, and QC reports for bulk customers — if you want a sample test we can help set that up.)

Pairing cells to driver types — quick rules of thumb

- Boost drivers (they step voltage up): prioritize stable voltage under load and low IR.

- Buck drivers (they step voltage down): these tolerate a wider input range but still benefit from high-capacity cells.

- Constant-current / regulated drivers: check startup draw and peak pulses — your cell must handle both the peak and sustained draws.

A short troubleshooting list

- Light flickers on high mode → likely sag / weak cell or poor contact. Try clean contacts and a fresh cell.

- Runtime worse than spec → check IR and real-world discharge curve rather than factory mAh.

- Charger shows odd voltages → test cells individually on a bench charger before assuming the charger is bad.

Final thoughts (and a little factory honesty)

Batteries are the quiet workhorses under the hood of any flashlight. If you want reliable performance, don’t buy on one number alone. Look for a balance of low internal resistance, appropriate continuous discharge rating, and consistent manufacturing quality.

If you’re a DIYer, hobbyist, or a small brand putting together runs of flashlights, ask your battery supplier for real test data, matched batches, and information about logistics/hazmat handling. Those conversations save time and prevent failures later.

If you’re curious about packs, spec sheets, or matched-batch samples from a manufacturer point-of-view, reply here or contact us at Himax Battery. We’re happy to share non-promotional technical info and test data — no sales pressure, just real specs so you can choose what works.

What cell format are you using in your daily carry light, and what behavior would you like to improve (runtime, throw, thermal performance)? I’ll try to answer with practical suggestions.

Find articles related to 18650 lithium ion batteries