The Role of Lithium-ion Batteries in the New Energy Revolution

Lithium-ion (Li-ion) battery technology sits at the center of the global transition toward decarbonized power systems. From supporting intermittent renewables to enabling electrified transport, Li-ion batteries provide the power density, efficiency and lifecycle performance required for modern energy systems. For engineers, OEMs and procurement teams, understanding how different Li-ion chemistries, pack designs and system integrations affect cost, reliability and performance is essential when specifying bulk purchases or architecting utility-scale projects.

This article explains the technical foundations, compares common Li-ion chemistries, outlines application-driven architecture choices, and provides procurement and validation guidance tailored for bulk buyers and system integrators.

Why Li-ion is the dominant choice for modern energy applications

Li-ion batteries combine several properties that make them uniquely suitable for renewable integration and electrification:

- High energy and power density — enabling compact energy storage and high-rate discharge for grid services.

- High round-trip efficiency — typically 88–95%, which reduces energy losses compared with alternatives.

- Rapid response and power controls — ideal for frequency regulation, peak-shaving and ancillary services.

- Maturing manufacturing base & supply chain — enabling scalable procurement and module-level customization.

These attributes mean Li-ion is often chosen for three primary roles in modern energy systems: (1) behind-the-meter commercial storage, (2) utility-scale battery energy storage systems (BESS), and (3) vehicle electrification.

Comparing Li-ion chemistries — strengths and tradeoffs

Different Li-ion chemistries trade energy density, cost, cycle life and safety. Below is a concise technical comparison useful when selecting cells for a given application.

Chemistry comparison table (practical guide)

| Characteristic | NMC / NCA (High-energy) | LFP (LiFePO4) | LTO (Lithium Titanate) |

| Typical energy density (Wh/kg) | 180–250 | 90–160 | 60–80 |

| Cycle life (to 80% capacity) | 1,000–2,000 | 2,000–6,000 | 7,000–20,000 |

| Safety & thermal stability | Moderate (better with additives) | Excellent (high stability) | Excellent (very stable) |

| Cost per kWh (cell level) | Mid–high | Low–mid | High |

| Fast charge capability | Good (needs thermal controls) | Good | Excellent |

| Operating temp range | −20°C to 60°C | −20°C to 60°C (robust) | −40°C to 65°C (excellent) |

| Best use cases | EVs where range is critical | Grid storage, UPS, telecom, ESS | Ultra-high cycle, extreme temp/fast charge use |

Selection guidance:

- Use NMC/NCA when maximizing specific energy (EV range) matters.

- Use LFP where cycle life, safety and low TCO are priorities (stationary storage, telecom, many B2B applications).

- Use LTO for extreme cycle life and fast-charge systems where cost is secondary.

System-level architecture choices for renewable integration

When integrating Li-ion into renewable systems, pack-level choices impact overall system performance and lifecycle cost.

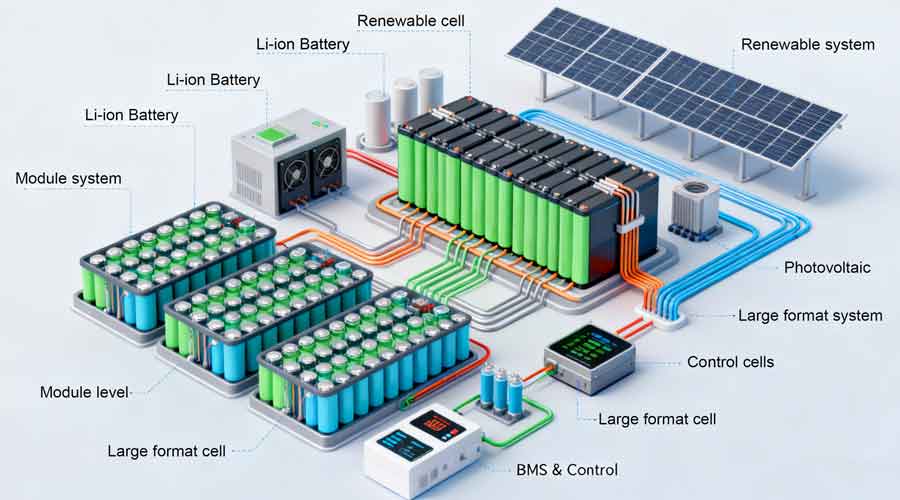

Modular vs large-format cells

- Modular small-format cells (18650, 21700): High packing efficiency, mature thermal management designs, well-suited for scalable BESS and EVs.

- Large-format pouch/prismatic cells: Lower assembly cost and simplified BMS wiring for some stationary applications; require robust mechanical support and pressure control.

BMS & controls

A proper Battery Management System (BMS) is critical — for cell balancing, thermal protection, state-of-charge (SOC) estimation and safety interlocks. For grid applications, BMS must integrate with EMS (Energy Management System) for charge/discharge scheduling, demand response and market participation.

Thermal management

Active liquid cooling gives the best performance for high-power applications; passive and air cooling can be adequate for many stationary systems but must be validated against worst-case duty cycles.

Performance KPIs and procurement metrics

Bulk buyers and engineers should include these measurable KPIs in RFQs and specs:

- · Cycle life at specified DoD and temperature (e.g., cycles to 80% capacity at 25°C, 1C, 80% DoD).

- Round-trip efficiency (system-level).

- Energy throughput guarantee (MWh over warranty period).

- Degradation rate (% capacity loss per year or per 1,000 cycles).

- Cell internal resistance and impedance growth profile.

- Safety certifications and test reports (IEC 62619, UN38.3, UL1973 where applicable).

Including measurable targets reduces ambiguity and speeds supplier qualification.

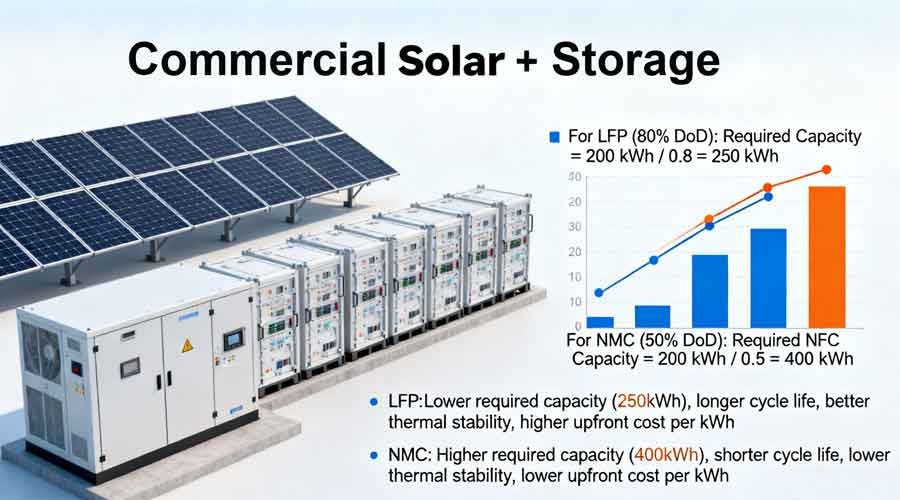

Example — sizing for a commercial solar + storage installation

Consider a commercial customer needing 200 kWh usable energy to manage peak demand and self-consumption. Design choices:

- Using LFP (80% DoD): pack nominal capacity ≈ 250 kWh.

- Using NMC (50% DoD recommended for long life): pack nominal capacity ≈ 400 kWh.

Trade-offs: LFP offers smaller nominal capacity, longer cycle life and better TCO; NMC may be more compact for the same nominal capacity but may require cell replacements sooner.

Procurement checklist for bulk buyers

- Define duty cycle: daily cycles, partial cycles, C-rate distribution, and expected calendar life.

2. Require standardized test data: cycle life, calendar life, low-temp performance, thermal runaway tests.

3. BMS/EMS integration requirements: communication protocols, safety interlocks, and control strategy.

4.Warranties tied to energy throughput: specify MWh warranty or remaining capacity guarantee over time.

5.Sample & pilot program: require sample modules and a short pilot deployment under real load.

How Himax Battery supports system integrators

Himax provides engineering and procurement support for large projects:

- Custom pack design to match cell chemistry and mechanical constraints. (See: /custom-battery-design/)

- LFP and other product lines optimized for energy storage and telecom. (See: /lifepo4-battery/)

- Pre-production pilot runs with performance reports, environmental testing and safety certifications.

- Integration support for BMS/EMS and commissioning.

Our goal is to convert energy-system requirements into validated hardware and predictable lifecycle economics.

Conclusion — practical advice for buyers

Li-ion batteries are the enabling technology for the new energy economy, but selecting the right chemistry, cell format and system architecture matters. Bulk buyers should focus on measurable KPIs, pilot validation and clear procurement specs that reflect duty cycle and performance goals. Partner with a manufacturer that can provide engineering depth, sample validation and supply certainty — qualities Himax delivers as part of our B2B offering.

CTA: For specification templates, pilot program quotes or modular sample packs, contact Himax Battery at services@himaxelectronics.com or visit himaxbattery.com/contact.

Find articles related to li-ion batteries