Choosing the right lithium-ion chemistry is a foundational decision for any product that relies on rechargeable batteries. Chemistry affects energy density, cycle life, thermal behavior, cost and the system requirements for BMS and thermal management. This guide compares common cathode and anode families (LFP, NMC, LCO, LTO, graphite, silicon) and gives procurement teams practical steps to validate a chemistry for volume use.

Why chemistry matters for procurement and system design

A chemistry label (e.g., “LFP” or “NMC”) is shorthand — real performance depends on electrode formulation, cell construction and supplier process control. Two cells that both claim “NMC” can behave very differently under fast charge or elevated temperatures. For buyers, the right chemistry reduces warranty costs, improves safety and matches product expectations (range, lifetime, weight).

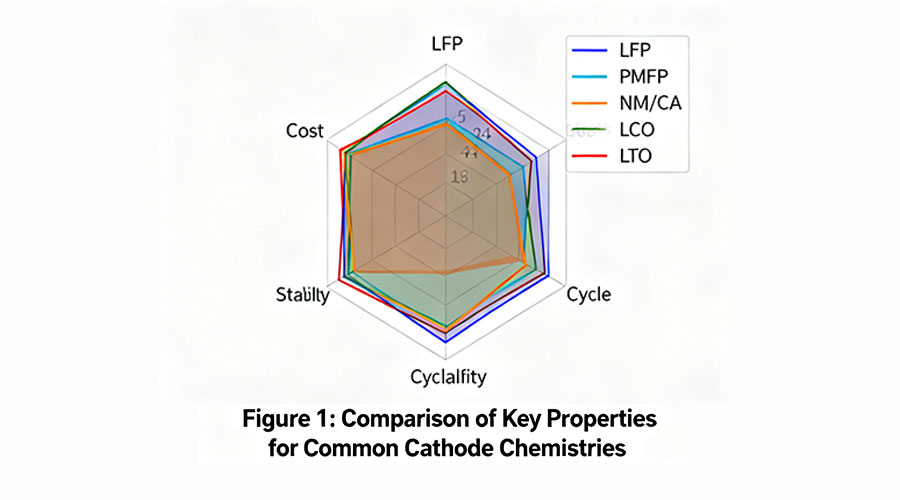

Cathode chemistries — quick comparison and use cases

LiFePO₄ (LFP)

· Strengths: exceptional thermal stability, long cycle life, strong safety profile.

· Tradeoffs: lower gravimetric energy density than nickel-rich chemistries.

· Best for: solar ESS, backup power, commercial EVs and any design prioritizing lifetime and safety over maximum energy per kg.

LMFP (Lithium Manganese Iron Phosphate)

· Strengths: higher energy than LFP (typically ~15–20% uplift) while keeping LFP’s thermal robustness.

· Status: commercially maturing — a good middle ground when you need more energy without sacrificing too much safety.

NMC / NCA (Nickel-rich chemistries)

· Strengths: higher practical energy density — favored in passenger EVs and portable devices.

· Tradeoffs: more sensitive to overvoltage and temperature; requires stricter thermal and BMS controls. Variants (e.g., NMC111 → NMC622 → NMC811) shift the nickel/cobalt/manganese balance, affecting cost and behavior.

LCO (Lithium Cobalt Oxide)

· Strengths: historically high energy density for compact consumer cells.

· Tradeoffs: cost, thermal tolerance and lifecycle are less favorable for heavy-duty or high-cycle applications.

LTO (Lithium Titanate Oxide)

· Strengths: exceptional rate capability, wide temperature tolerance and very long cycle life.

· Tradeoffs: lower energy density; used where fast charge/discharge and longevity dominate the requirements (e.g., industrial, cycling infrastructure).

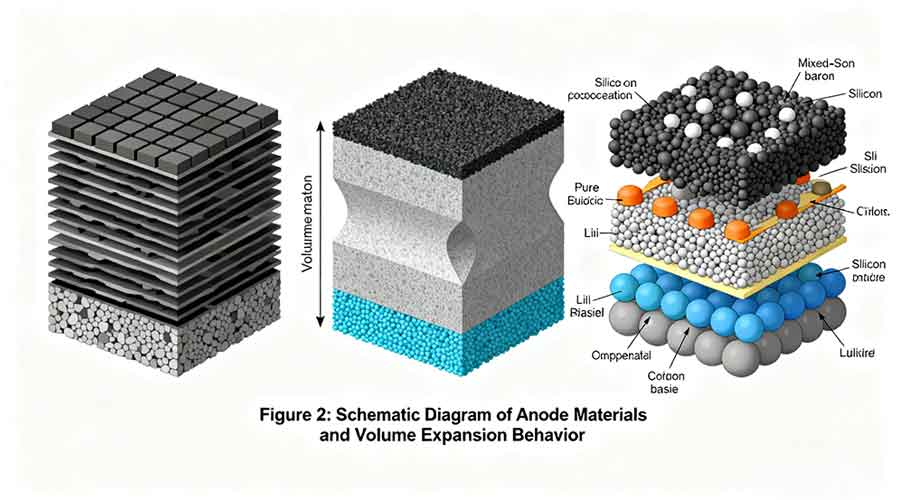

Anode options — graphite, silicon and hybrids

Graphite

The workhorse anode: stable, predictable, good cycle life. Most commercial cells use graphite or graphite blends.

Silicon (composite or additives)

Silicon offers a step-change in theoretical capacity but brings up to ~400% volume expansion on lithiation. Practically, silicon is blended into graphite electrodes in limited fractions or engineered as composite structures to boost energy without destroying cycle life.

LTO (as anode variant)

When used as an anode, LTO enables extreme rate and safety characteristics at the cost of cell energy density.

Electrode engineering — why details beat labels

A cell’s behavior depends on electrode formulation (particle size, binder, conductive additive), coatings, and manufacturing quality. Ask suppliers for electrode composition or at least high-level specs: are silicon additives used, what binder chemistry is chosen, and how is electrode porosity controlled? These details impact fast-charge tolerance, swelling, and cycle fade.

Practical selection checklist for procurement teams

When evaluating cells or packs, require the following documented evidence before approving a supplier:

- Datasheet with recommended charge/discharge profiles — explicit max charge voltage, recommended C-rate, and temperature window.

2. Cycle life data tied to specific charge profiles — e.g., capacity retention after 500 cycles at your intended charge/discharge settings.

3. Fast-charge test reports (if needed) — capacity fade, DC internal resistance growth and temperature rise under the proposed fast-charge curve.

4. BMS requirements & pack integration notes — per-cell sensing, balancing approach (passive vs active), protection thresholds.

5. Thermal characterization — temperature rise under charge/discharge and any recommended thermal mitigation.

6. Compliance and transport paperwork — UN38.3, IEC test reports (e.g., IEC62619 where applicable).

7. Supply chain & raw material risk statement — especially if your design relies heavily on nickel or cobalt ratios.

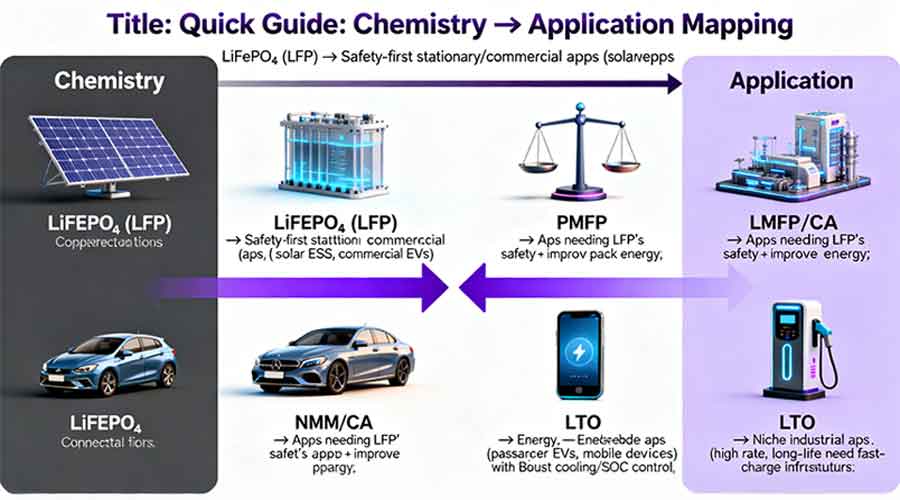

Rules of thumb: chemistry → application mapping

· LFP: safety-first stationary and commercial applications.

· LMFP: when LFP’s safety is needed with improved pack energy.

· NMC/NCA: energy-dense applications (EVs, mobile devices) where system cooling and SOC control are robust.

· LTO: niche high-rate, long-life industrial applications.

How to avoid common pitfalls

· Don’t accept generic chemistry labels — insist on supplier test data under your real use conditions.

· Match BMS and thermal design to chemistry: nickel-rich cells that promise fast charge must come with stricter cell-level monitoring and cooling.

· If you rely on silicon-enhanced anodes, request swelling/expansion data and long-term calendar life tests.

Short procurement-ready summary (one paragraph)

Chemistry choice is a systems decision: energy density, cycle life, safety and thermal behavior are products of both active materials and how the cell is engineered and managed. For bulk buyers, require datasheets, age-related cycle data tied to your charge profile, thermal and fast-charge test reports, and explicit BMS integration notes before approving any cell or pack.

FAQ (add these as visible content and include in JSON-LD)

Q: What is the safest chemistry for long life?

A: LiFePO₄ (LFP) is widely recognized for thermal stability and long cycle life, making it a top choice where safety and longevity matter.

Q: Can all cells be fast-charged?

A: No. Fast charge tolerance depends on cell chemistry, electrode formulation and thermal management. Always request fast-charge test data for your intended profile.

Q: What should I request from a supplier before purchase?

A: Datasheets, cycle life tests under your charge/discharge profile, thermal rise reports, BMS integration notes and compliance paperwork (UN38.3, IEC reports).

About Himax Battery (CTA)

Himax Battery supports chemistry selection, cell sourcing and complete pack engineering for industrial, solar and mobility customers. We perform charge-profile tuning, BMS co-design and lifecycle testing to validate chemistry choices for your product. Request samples or technical datasheets at services@himaxelectronics.com or visit https://himaxelectronics.com/contact.

testing: services@himaxelectronics.com or https://himaxelectronics.com/contact.

Find articles related to lifepo4 batteries

- Recommended Himax LiFePO4 Battery Models

- The Ultimate Guide to Charging Lithium Iron Phosphate (LFP) Batteries: Voltage, Charging Curves, and Best Practices