By Himax Battery

Charging a battery sounds straightforward — push current into the cells until they’re full. In practice, charging is where chemistry, heat, electronics and system-level engineering intersect. The charging strategy you choose directly affects safety, cycle life, and total cost of ownership. For procurement teams and system integrators buying battery packs in volume, charging specs should be treated as core acceptance criteria, not optional documentation.

COMMON CHARGE METHODS — WHAT ENGINEERS USE

Engineers deploy a handful of pragmatic charging methods depending on cell chemistry, available power, and product requirements:

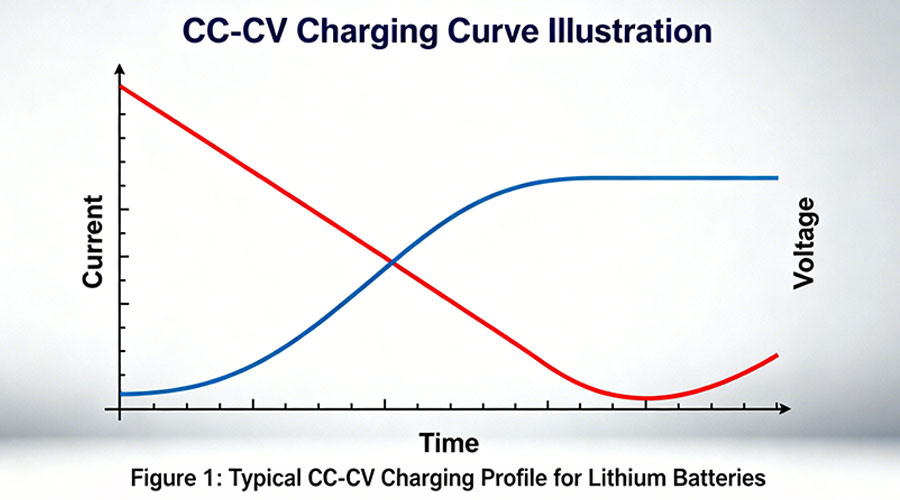

• CC–CV (Constant Current → Constant Voltage)

The industry default for most lithium cell types. Charge at a stable current until pack voltage reaches the target; then hold that voltage while current tapers off. It is robust, predictable and typically backed by cell manufacturers’ datasheets.

• CP–CV (Constant Power → Constant Voltage)

Useful when upstream power is constrained or when charging through an inverter; it limits power draw rather than current.

• Multi-stage or stepped CC–CV

A compromise between speed and longevity: higher current during the initial stage, then stepped reductions to control heating and reduce stress.

• Pulsed or variable profiles

Occasionally used to manage thermal spikes or ionic transport. These profiles can offer benefits but add complexity and require careful validation.

KEY LIMITS YOU MUST RESPECT

When evaluating cells or packs, insist that suppliers provide explicit limits tied to their charging recommendations:

• Maximum charge voltage (per cell) — Exceeding the recommended upper voltage accelerates side reactions and increases safety risk. Use the cell maker’s upper-voltage limit as the hard spec.

• Maximum charge current / C-rate — Faster charging shortens time-to-charge but increases heat and accelerates ageing. Choose a maximum C aligned with the cell’s proven performance.

• Temperature window — Charging outside the recommended temperature range (both cold and hot) damages cells or triggers protection. Derating or thermal management is required for reliable operation.

• Per-cell monitoring — Pack-level voltage alone is insufficient. BMS must monitor individual cells to prevent imbalance-driven issues.

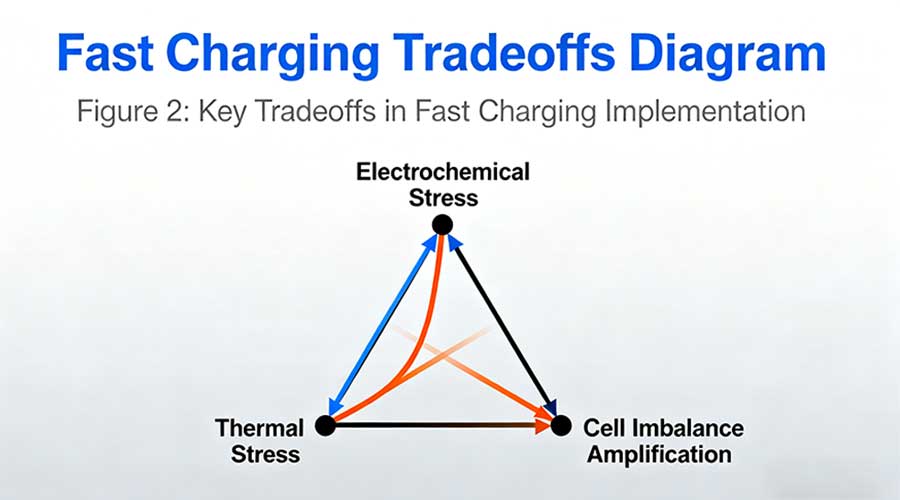

FAST CHARGING — THE TRADEOFFS

Fast charging is a headline feature for users, but it compounds three problems:

- Electrochemical stress — higher currents speed up side reactions that reduce capacity and can cause lithium plating under certain conditions.

- Thermal stress — fast charge generates more heat; without robust thermal design or active cooling the pack will reach protective thresholds or suffer accelerated degradation.

- Cell imbalance amplification — differences in capacity and internal resistance between cells become more consequential under high currents, requiring more capable BMS balancing.

In short: fast charging is not just “more current.” It demands co-optimized cell chemistry, thermal strategy, and BMS capability, validated with real-world testing.

PRACTICAL RECOMMENDATIONS FOR PURCHASERS & INTEGRATORS

When you evaluate suppliers or accept a pack design, make charging requirements a formal part of your technical acceptance checklist:

- Request the recommended charge profile and ageing data

— Ask for CC/CV curves, the recommended max C-rate, and cycle life data tied to the supplier’s stated charge profile.

- Verify BMS capability

— Confirm per-cell voltage sensing, balancing method (passive/active), protection thresholds (over/under voltage, over/under temperature, overcurrent) and logging/telemetry features if needed.

- Require fast-charge cycle tests (if you intend to fast charge)

— Test under your specific charge curve and expected ambient conditions. Track capacity fade, DC internal resistance growth and any anomalous events.

- Specify thermal management

— For packs designed to support high C charging, demand temperature rise figures under load and proof of any active cooling strategy.

- Collect compliance and transport paperwork

— Include UN38.3, IEC test reports and any other relevant certificates in your purchase acceptance criteria.

CHEMISTRY NOTES — QUICK GUIDANCE

Different lithium formulations tolerate charge differently:

• LiFePO₄ (LFP) — More thermally stable and often more forgiving at higher currents; ideal for safety-oriented, long-life applications.

• NMC / NCA — Higher energy density but more sensitive to overvoltage and temperature; fast charging is possible but requires conservative control and stronger thermal management.

Always validate against the specific cell datasheet. Labels like “NMC” or “LFP” describe broad families — performance varies by formulation and vendor.

SHORT BUYING CHECKLIST (ONE PAGE)

Before signing a PO or approving a pack design, confirm in writing:

• Recommended charge profile (voltage, current, temperature limits) from the cell supplier.

• BMS feature list and balancing strategy.

• Fast-charge test results for your target profile and ambient conditions.

• Compliance documents (UN38.3, IEC/other applicable reports).

• Warranty terms tied to specified charge regimes.

CONCLUSION — MAKE CHARGING A CONTRACT ITEM

Charging strategy influences user experience, lifecycle cost, and safety. For bulk buyers and integrators, the simplest way to reduce risk is to demand charge profiles and test data up front, ensure BMS capabilities match the pack’s charge ambitions, and validate fast-charge claims under your expected use conditions. Those steps turn marketing claims into predictable engineering outcomes.

ABOUT HIMAX BATTERY (OPTIONAL CTA)

Himax Battery supplies custom LiFePO₄ and lithium-ion packs for industrial, solar and mobility applications. We offer engineering support for charge profile tuning, BMS integration and fast-charge lifecycle testing. To request samples or a custom technical datasheet, contact our sales team at services@himaxelectronics.com or visit https://himaxelectronics.com/contact.