Exploring the Intelligence Behind Modern Energy Systems

“The battery is a wild animal—and intelligence is what domesticates it.”

— A reflection often heard in the battery industry, and one that captures the essence of modern smart battery design.

Understanding the Nature of the Battery

Unlike mechanical systems that show visible wear or performance degradation, batteries often appear unchanged — whether full or empty, new or aging. This invisibility of their internal condition has long challenged users and engineers alike.

Three key uncertainties define this challenge:

- Unknown Remaining Runtime: Users rarely know exactly how much energy is left.

- Uncertain Power Capability: Devices can’t easily predict if a battery can meet high power demands.

- Charger Compatibility: Each battery type requires a specific charging algorithm and chemistry profile.

Smart battery technology was developed to bridge these gaps — adding data, control, and communication to what was once a silent energy source.

Beyond the Fuel Tank Analogy

It’s tempting to think of a battery as a fuel tank that stores and releases energy. But while fuel levels in a tank can be directly measured, a battery’s state-of-charge (SoC) depends on electrochemical reactions that are complex, nonlinear, and influenced by temperature, aging, and usage history.

Unlike liquid fuel measurement:

· A battery’s open-circuit voltage (OCV) only loosely reflects its SoC.

· Capacity fades over time, meaning that even a “full” reading may represent only half of the original energy.

· Voltage under load can fluctuate, making instant readings unreliable.

This is why a simple voltage-based gauge is no longer sufficient for modern systems that demand reliability, predictability, and precision.

The Birth of the Smart Battery

The introduction of “smart” batteries marked a turning point. These are not merely power sources but data-driven subsystems capable of communicating with host devices and chargers.

Smart batteries are now standard in:

· Medical devices requiring strict safety and runtime assurance.

· Defense and aerospace systems with high reliability needs.

· Computing and industrial equipment that depend on energy predictability.

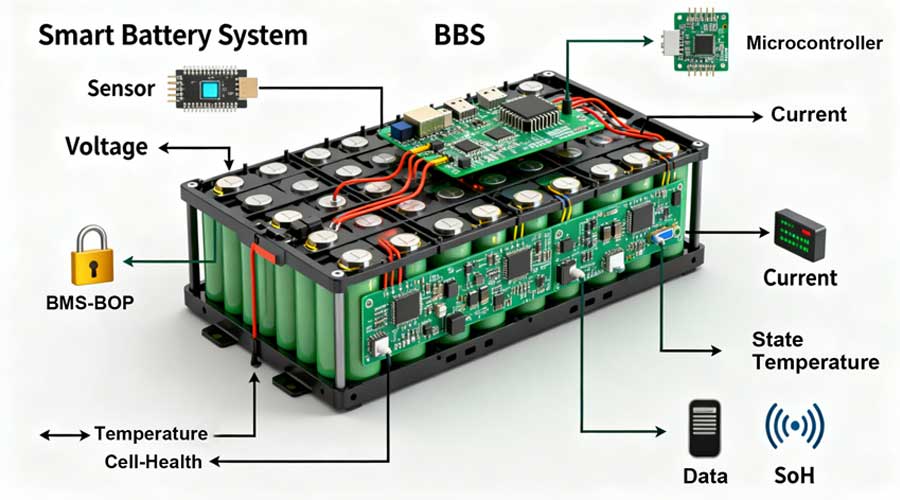

The Smart Battery System (SBS) concept integrates sensors, microcontrollers, and communication circuits within the pack. Together, they form a closed-loop architecture that monitors and manages performance parameters such as voltage, current, temperature, and state-of-health (SoH).

Safety and Communication: The Core of SBS

Placing intelligence within the pack enhances safety. The SBS continuously communicates with the host and charger, ensuring:

· Accurate charge termination based on both digital data and analog feedback.

· Redundant temperature monitoring to prevent overheat conditions.

· Real-time updates to support preventive maintenance and user alerts.

Evolution of Smart Battery ICs

The first commercial fuel-gauge ICs appeared in 1990, developed by Benchmarq. Today, many ICs follow standardized protocols such as 1-Wire and SMBus, allowing interoperability across diverse platforms.

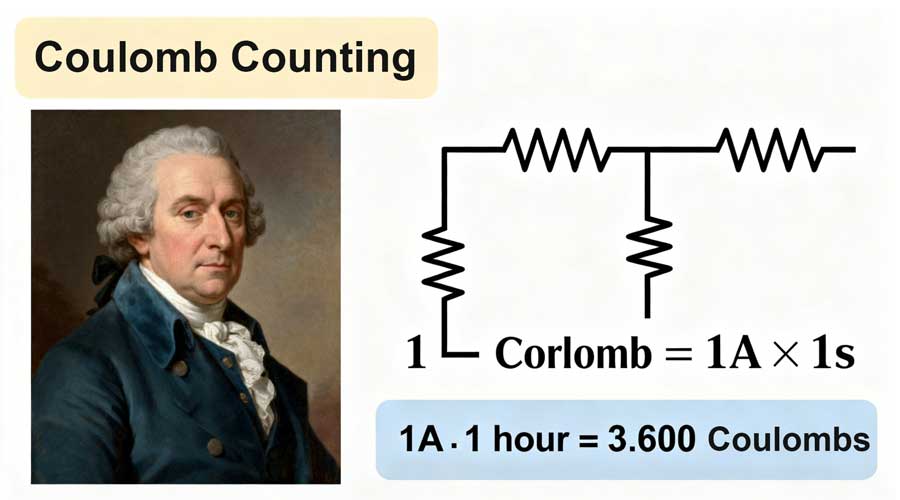

Coulomb Counting — Measuring the Flow of Energy

| Parameter | Definition |

| 1 Coulomb (C) | Charge transferred by a current of 1 ampere in 1 second |

| 1 A for 1 hour | 3,600 Coulombs of charge flow |

At the heart of every smart battery lies the Coulomb Counting principle, developed from Charles-Augustin de Coulomb’s 18th-century experiments. It measures charge by tracking current flow over time:

However, no battery is perfectly efficient — energy losses during charging, discharging, and aging mean that the output is always less than the input. Smart fuel gauges use advanced algorithms to correct for these variations.

Smart Battery Communication Systems

1. Single-Wire System (1-Wire)

Developed by Dallas Semiconductor, this system combines data and clock signals on one wire. It stores essential data such as voltage, current, and SoC.

Typical Applications:

· Handheld devices

· Two-way radios

· Mobile scanners

· Portable measuring instruments

Its low cost makes it ideal for compact devices, though each manufacturer often uses proprietary communication protocols.

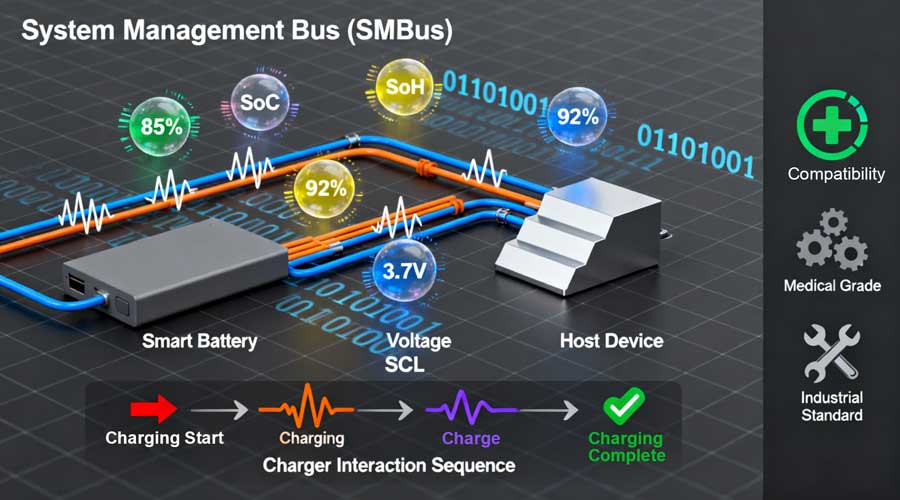

2. System Management Bus (SMBus)

Introduced in 1995 through a Duracell/Intel initiative, the SMBus uses a standardized two-wire protocol derived from I²C.

Key Benefits:

· Supports state-of-charge (SoC) and state-of-health (SoH) monitoring.

· Enables smart charging, where the battery instructs the charger — not the other way around.

· Provides universal compatibility across chemistries and devices.

Example Implementations:

The Sony and Hitachi 35 and 202 Series SMBus batteries powered early laptops and biomedical devices. While the concept of standardization was strong, proprietary coding by manufacturers soon fragmented the market to prevent unauthorized battery use.

Smart Battery Data Architecture

| Type | Content | Persistence |

| Permanent Data | Manufacturer ID, battery type, serial number, production date | Stored permanently |

| Temporary Data | Cycle count, usage history, temperature, maintenance records | Updated dynamically |

Resolution levels are typically 1mV for voltage, 0.5mA for current, and ±3°C for temperature accuracy.

SMBus Charger Levels

| Level | Description | Application |

| Level 1 | Discontinued — limited to a single chemistry | Legacy systems |

| Level 2 | Fully controlled by the smart battery; charger acts as slave | Laptops, built-in chargers |

| Level 3 | Hybrid system where charger can also act as master | Industrial and biomedical instruments |

Level 3 systems dominate in professional environments where reliability and compliance are critical.

Advantages and Limitations of Smart Batteries

| Advantages | Limitations |

| Accurate state-of-charge and full capacity estimation | Increases cost by ~25% |

| Automatic charger configuration | Requires periodic calibration |

| Service reminders and maintenance tracking | Adds charger complexity |

| Protection from unauthorized battery use | SoC does not directly indicate runtime |

Best Practices for Using Smart Batteries

· Regular Calibration: Perform a full charge–discharge cycle every 3 months or 40 partial cycles to maintain gauge accuracy.

· Validate Actual Capacity: A full SoC reading doesn’t always mean full capacity — aging can reduce runtime to 50% or less.

· Use Compatible Brands: Prevent communication or charging mismatches by pairing batteries with the same OEM system.

· Monitor Anomalies: Incorrect SoC reporting may indicate a communication issue or pack fault.

Conclusion: Intelligence Drives Reliability

Smart batteries are more than just energy sources — they are intelligent subsystems that transform how energy is stored, managed, and understood.

At Himax, we believe that intelligent battery design is key to building safer, more efficient, and longer-lasting power systems. By integrating precise sensing, reliable communication, and adaptive control, smart batteries redefine what’s possible in portable energy management — from industrial automation to next-generation mobility.