As a battery design engineer at Himax Battery, I’ve always believed that a well-engineered battery is more than a component—it’s the heart of innovation. Every project starts with a customer’s unique challenge: a medical device that must stay light and reliable, a robot that needs high discharge efficiency, or an industrial control system requiring long-term stability.

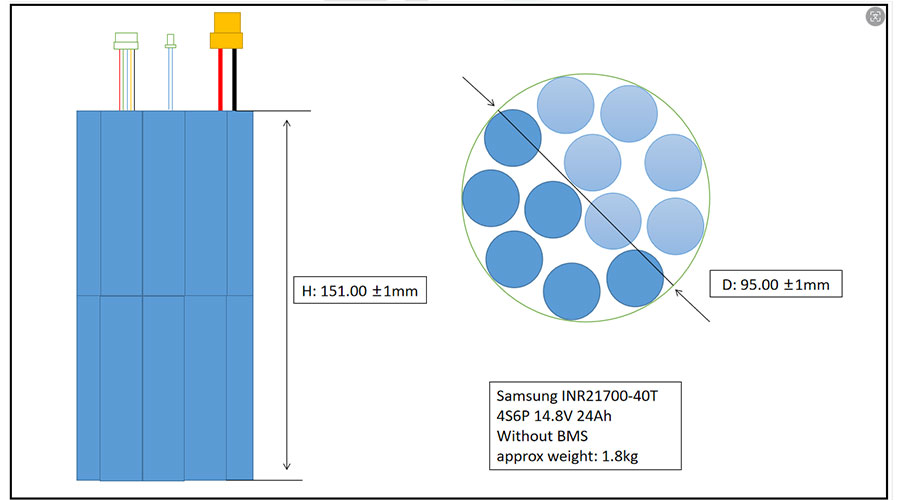

Recently, I had the privilege of designing one of our most versatile solutions — the Himax 14.8 V 18 Ah lithium-ion battery pack, model BATTERY-L-4S-18AH — a compact yet powerful system built with INR18650-30Q cells. This project taught us once again how precision, chemistry, and empathy come together to create performance that truly fits our customers’ needs.

1. Core Technical Specifications

| Parameter | Specification |

| Cell Type | Lithium-ion (INR18650-30Q) |

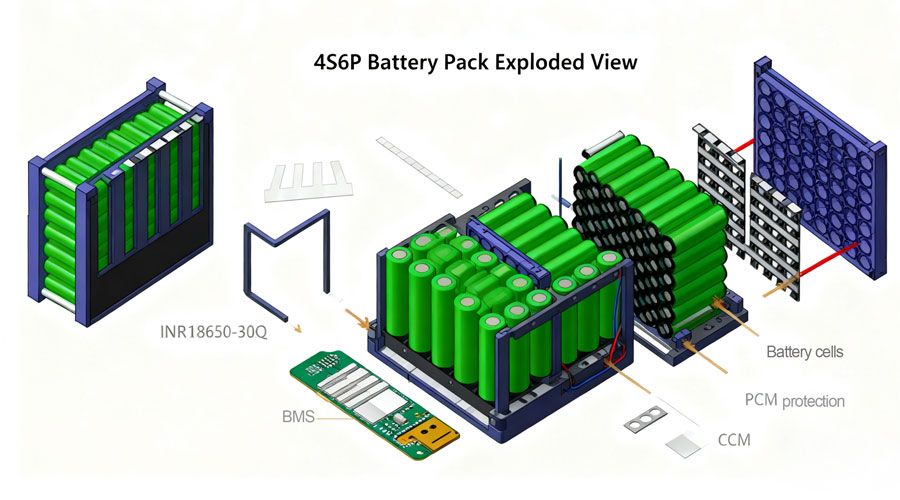

| Configuration | 4S6P (24 cells total) |

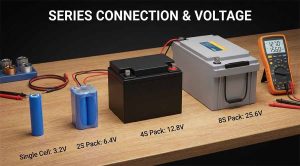

| Nominal Voltage | 14.8 V |

| Nominal Capacity | 18 Ah |

| Energy | 266.4 Wh |

| Standard Charge | 16.8 V, 3.6 A (CC/CV mode) |

| Max Charge Current | 9 A |

| Standard Discharge Current | 3.6 A |

| Max Continuous Discharge Current | 60 A (120 A pulse, 1 s) |

| Discharge Cut-off Voltage | 10 V |

| Cycle Life | ≥ 250 cycles (≥ 60% capacity retention) |

| Weight | Approx. 1.2 kg |

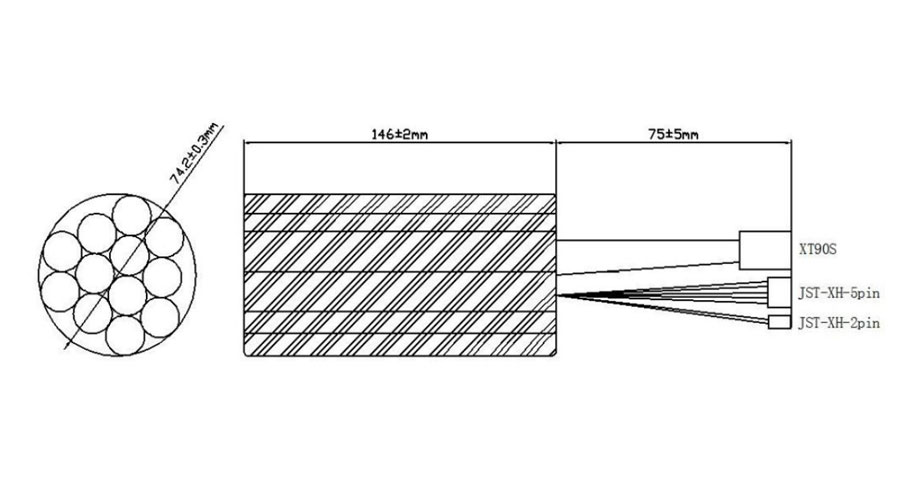

| Dimensions | Ø 74.5 mm × 148 mm |

| Operating Temperature | Charge 0–45 °C / Discharge –20–60 °C |

| Storage Temperature | –10–45 °C |

| Connectors | XT90S / JST-XH (5 pin & 2 pin) |

| Internal Resistance | ≤ 20 mΩ |

This pack offers the perfect balance of power density, durability, and safety, suitable for industrial robots, surveillance systems, portable equipment, and automated tools that demand both lightweight construction and high current delivery.

2. Designed from the Inside Out

The foundation of this battery lies in the Samsung INR18650-30Q cells, selected after analyzing multiple chemistries for energy density and cycle behavior.

Our 4S6P configuration provides a robust 18 Ah capacity, while maintaining voltage stability under heavy load. With a continuous discharge current of 60 A, it effortlessly powers systems that require strong surge performance, such as UAV propulsion modules or motor-driven tools.

From an engineer’s perspective, every component — from the 10 AWG output cable to the XT90S anti-spark connector — was chosen not only for performance, but for the specific application profile of our client’s device.

That’s what sets custom lithium battery packs apart from standard catalog products: they’re tuned to the system, not the other way around.

3. Built-In Protection and Reliability

Each Himax custom battery pack integrates a Protection Circuit Module (PCM) designed to prevent overcharge, over-discharge, short circuit, and overcurrent events.

During testing, we simulate extreme mechanical and electrical stresses — crush tests, vibration cycles, and short-circuit conditions up to 150 °C — to ensure that no fire, smoke, or explosion occurs.

When I hold the final prototype in my hands after a full compliance validation (GB/T18287-2013, UL1642, CE61960), I don’t just see numbers and graphs — I see safety engineered into every ampere.

4. Electrical Performance in Real-World Conditions

In field applications, the 14.8 V 18 Ah pack shows remarkable voltage stability and thermal consistency.

Even after 28 days of idle storage at 20 °C, the pack retains over 90% capacity, and under –10 °C, it still delivers 75% discharge efficiency — a testament to the balanced chemistry and internal design.

These details matter to system integrators. A well-behaved discharge curve can mean hours of extended operation and reduced calibration time for their end product.

That’s why we tailor each pack’s BMS parameters, wire gauge, and connector type to align perfectly with our clients’ current profiles and design constraints.

5. Customization: The Himax Design Philosophy

When clients approach us, they don’t just want a battery—they want a solution. Some ask, “Can you help reduce my system’s weight?” Others want to extend operational time without redesigning their PCB.

As Himax engineers, we start by asking questions:

· What’s your operating temperature range?

· How much peak current do you need?

· Is your device portable, fixed, or automotive-grade?

Then we model the power consumption, select optimal cell chemistry, and configure pack geometry.

Sometimes, switching from a 3.6 V NMC cell to a 3.2 V LiFePO₄ architecture saves the customer cost and enhances safety; in other cases, a higher energy NCA chemistry boosts run-time without changing the housing.

Every design is an engineering conversation — and that’s what makes working at Himax Battery so rewarding.

6. Tested for Safety and Long-Term Value

Each pack undergoes multiple safety verifications, including:

· Drop Test: 1 m onto concrete — no fire or leakage.

· Vibration Test: 10–55 Hz for 30 min per axis — stable structure, no failure.

· Heating & Crush Tests: up to 130 °C and 13 kN — no explosion or venting.

These are not just tests — they’re promises of quality. For our industrial clients, reliability means fewer replacements, lower downtime, and long-term cost savings.

7. Partnering for Power: Himax Custom Battery Services

Our custom battery services include:

· Electrical and Mechanical Design (voltage, capacity, discharge rate optimization)

· BMS Development (protection thresholds, communication protocols)

· Prototype Testing and Certification Support (UN 38.3, IEC 62133, CE, UL)

· Mass Production and Supply Chain Integration

From prototype to production, our mission is simple: deliver a battery pack that fits perfectly into your system—technically, mechanically, and economically.

When a customer sends me a message saying, “Your pack made our equipment lighter and doubled its runtime,” that’s the real satisfaction of being a battery designer.

8. Conclusion

The Himax 14.8V 18 Ah Li-ion battery pack represents the essence of what we strive for: engineering precision blended with customer empathy.

By choosing Himax, you’re not just buying a power source — you’re gaining a design partner committed to efficiency, safety, and innovation.

Whether you need a compact pack for portable electronics or a robust energy module for industrial robotics, our team of Himax Battery engineers is ready to help you design smarter, perform longer, and save more.