As a senior battery design engineer at Himax Battery, I frequently get asked: “How far can I discharge before it damages my battery pack lifecycle?” In the world of lithium-ion and related chemistries (e.g. NMC, LFP), the depth of discharge (DoD) is a critical design variable. Choosing the right DoD not only influences cycle life but also affects system cost, weight, and customer satisfaction.

This paper analyzes empirical data from “How to Extend Lithium Battery Life,” integrating the latest academic research to explain how Himax batteries utilize depth of discharge (DoD) as an optimization tool to achieve performance enhancements and cost reductions in customized battery syst.

Key SEO keywords: depth of discharge lithium batteries, DoD cycle life, Himax Battery design, lithium battery longevity, NMC vs LFP cycle life.

What is Depth of Discharge (DoD) and Cycle Life

· Depth of Discharge (DoD) is the fraction (percentage) of battery capacity used per discharge cycle. Example: if a battery is fully discharged from 100% to 20%, that’s 80% DoD.

· Cycle life refers to how many full equivalent cycles (often to a given capacity fade threshold, e.g. 70-80% of original) a battery can complete under specified DoD, temperature, current rate, etc.

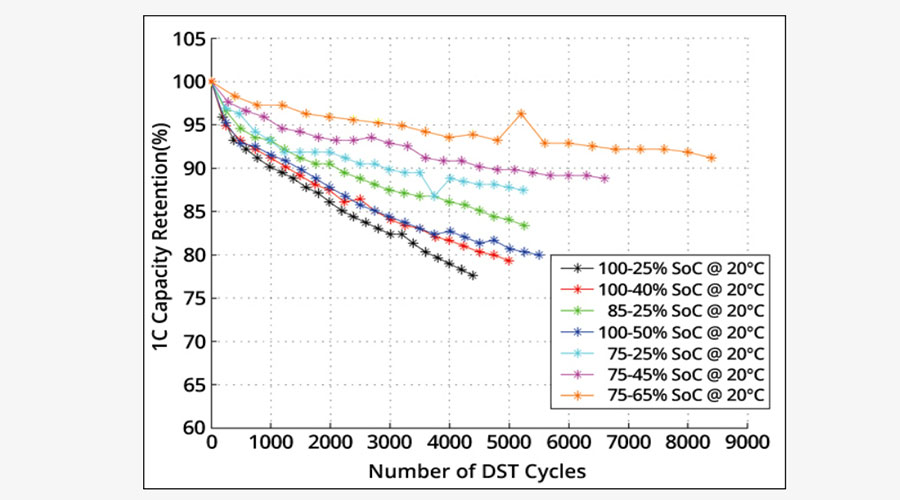

Lower DoD tends to increase cycle count dramatically, albeit at the cost of delivering less energy per cycle.

Empirical Data: DoD vs Cycle Life

Here are distilled numbers for common cobalt-based Li-ion cells (e.g. NMC) and lithium iron phosphate (LFP) chemistries:

| Depth of Discharge (DoD) | Approximate Cycle Life | Comments |

| 100% DoD | ~300 cycles (NMC), ~600 cycles (LFP) before ~70% capacity fade. | Full discharge places high stress. Useful if maximum energy per cycle is required. |

| 80% DoD | ~400 cycles (NMC), ~900 (LFP) | Common in moderate to heavy use applications. |

| 60% DoD | ~600 cycles (NMC), ~1,500 (LFP) | A trade-off region: good energy per cycle, reasonable cycle life. |

| 40% DoD | ~1,000 cycles (NMC), ~3,000 (LFP) | Often used in energy storage systems or backup power where lifetime matters. |

| 20% DoD | ~2,000 cycles (NMC), ~9,000 (LFP) | Low stress, high longevity; but energy per cycle is low. |

| 10% DoD | ~6,000 cycles (NMC), ~15,000 (LFP) | Very shallow cycling; useful in specialized systems where frequent recharging is acceptable. |

These numbers refer to cycles until capacity drops to about 70% of original. Also important: operating temperature, current rate, and voltage limits significantly influence those cycle numbers.

Deeper Insights & Recent Studies

To further refine design, Himax engineers incorporate newer findings:

- Chemistry Differences (NMC vs LFP vs Others): LFP tends to handle deeper discharges and more cycles under harsh DoD and temperature conditions. Recent research (e.g. Degradation of Commercial Lithium-Ion Cells as a Function of Chemistry and Cycling Conditions) shows that even when adjusted for energy throughput, LFP offers higher total cycle count under low to moderate discharge stresses.

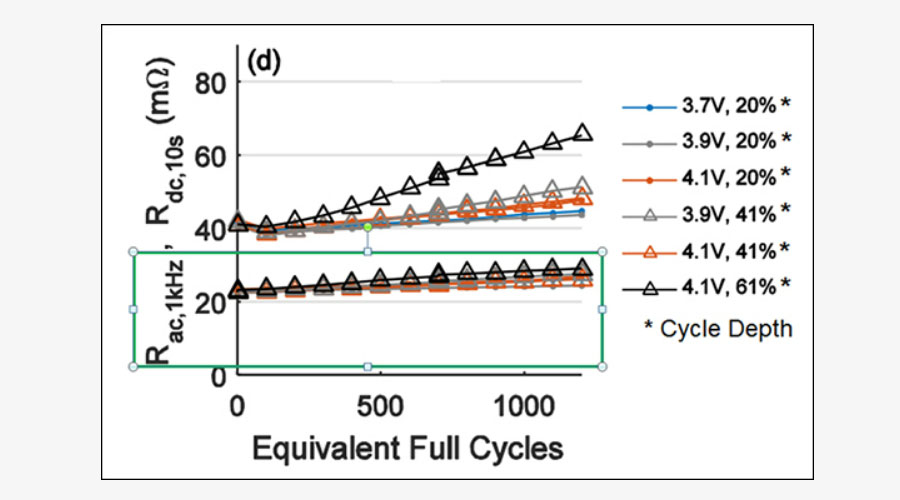

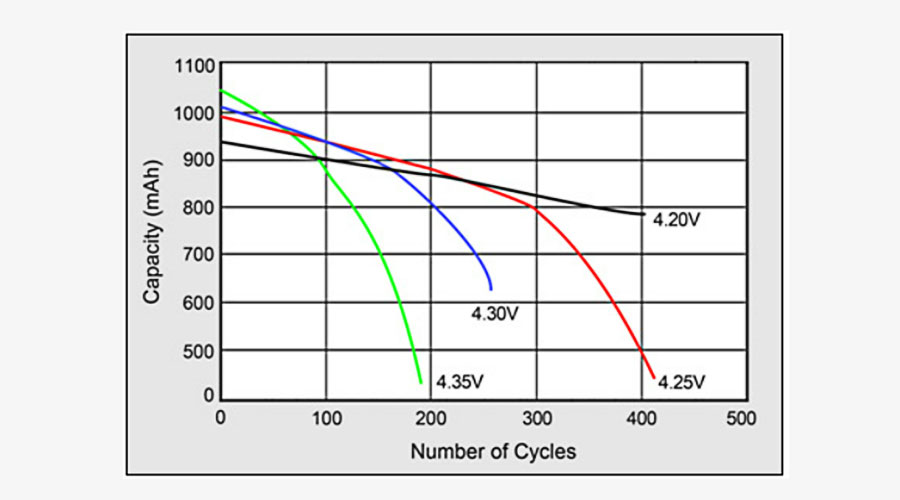

- Voltage Cut-offs and Charge Voltage Limits: High charge voltage (e.g. charging to 4.20-4.30V per cell) increases stress, especially under high DoD. Lowering the peak voltage by 0.1V to 0.2V can nearly double cycle life in many cases, at the cost of some energy density. BU-808’s tables show this clearly.

- Temperature Effects: Elevated temperatures exacerbate DoD stress. For example, storing or cycling at 40-60 °C greatly accelerates capacity fade. Best practice is to keep operating and charging temperatures low (say 25-30 °C or lower) in moderate use.

- Energy Throughput vs Cycle Count: It’s not just number of cycles: total delivered energy over battery life is a more meaningful metric. A battery cycled shallowly many times may deliver more cumulative energy even if cycle count is higher. Himax design considers energy delivered per cost (Wh per $) over lifetime.

How Himax Battery Designs to Optimize DoD for Customer Benefit

As a battery system designer, here’s how I apply DoD data to optimize packs for our customers:

· Match DoD to the Application Profile:

For applications like backup power or stationary ESS, where battery can be recharged frequently, we design for shallow-to-moderate DoD (20-60%) to maximize cycle life. For portable power tools or EVs, customers often demand larger usable capacity per cycle; in that case we allow higher DoD but adjust chemistry (e.g. choose cells with robust cathode materials, LFP or high-nickel NMC) or more conservative voltage cut-offs.

· Voltage Window Engineering:

We set charge voltage ceilings and discharge cut-offs such that the DoD doesn’t include extremes that stress the battery. For example, preventing discharge below a safe voltage (say 2.5-3.0V per cell in many NMC chemistries) and limiting charge to e.g. 4.10V instead of 4.20V helps extend life especially under deeper DoDs.

· Thermal Management:

When deeper DoD is required, we ensure effective thermal control: cooling, heat dissipation, avoiding long durations at high temperature or in high SoC with high DoD events. Because as BU-808 shows, DoD stress compounds with temperature stress.

· Custom BMS & Usage Profiles:

Himax’s custom battery services include configurable BMS (battery management systems) that can be programmed to limit depth of discharge in usage (e.g. only allow 80% of full capacity), or to manage charging so that frequent partial cycles are handled gently, minimizing stress.

· Selecting Cell Chemistry with Right Tradeoffs:

If a customer needs high usable energy and accepts fewer cycles, we may choose high-energy NMC; if lifetime and safety are priorities (e.g. energy storage, mission-critical systems), we lean toward LFP which shows greater tolerance for many DoD/temperature/cycle combinations.

Design Case Example

Let me walk you through a hypothetical design scenario:

A client making mobile medical diagnostic equipment wants a battery pack that can deliver ~8 hours of runtime between recharges, and expects >3 years field life (~1,500 cycles), with occasional operation in warm climates (up to 45 °C).

· Using BU-808 data: To achieve ~1,500 cycles, a DoD of ~60% (or lower) is safer. If 80% DoD is used, cycle count drops.

· We select an LFP cell with high cycle durability. We set charger to limit to ~4.05V instead of full 4.20V. We design the battery usage (runtime vs recharge interval) so typical discharge is between 85% → 25% (≈60% DoD), with cell resting periods.

· Also, thermal design ensures that during discharge the internal temperature remains under ~35 °C.

This approach results in a battery pack meeting the client’s runtime, with >1,500 cycles (at or above ~70-80% capacity retention), reduced maintenance or warranty costs, and lower lifecycle cost per Wh.

Trade-Offs: Usable Capacity vs Lifetime vs Cost

Of course, there are trade-offs. Decreasing DoD (i.e. using only part of the battery’s capacity per cycle):

· Reduces energy delivered per cycle → may require more frequent recharging or larger capacity to meet uptime.

· Increases cost per usable Wh initially (because you need more cells or capacity).

But over lifetime, shallower cycling often reduces total cost per delivered Wh by reducing replacement frequency and reducing maintenance. Himax uses total cost-of-ownership (TCO) modeling to find the optimal DoD / capacity combination per customer.

Recommendations for Users & OEMs (from Himax Battery’s Perspective)

- Define usage profile before selecting battery design — how many hours per use, how frequently, environmental temperature, charging behavior.

- Set conservative voltage limits — limit peak charge voltage when possible, avoid deep discharge below safe thresholds.

- Limit frequent high DoD use unless cell chemistry is designed for it — if you expect many deep discharge cycles daily, select cells rated for high DoD and high durability (often LFP or advanced NMC variants).

- Implement BMS policies — charge scheduling, state-of-charge window locking, thermal monitoring, and rest periods.

- Monitor capacity fade early — use early cycle data to adjust system settings, track how actual cycle life compares with predictions (from BU-808 and lab data) so design adjustments can be made in next iterations.

Conclusion

Depth of Discharge is one of the most powerful levers in battery design. Controlling DoD with smart chemistry choice, voltage windows, thermal management, and BMS calibration allows designers to extend cycle life significantly.

At Himax Battery, we blend empirical research, the latest academic findings, and deep understanding of customer needs to deliver battery packs that are optimized, long-lasting, safe, and cost-effective.

If you are an OEM, integrator, or system designer, we welcome the opportunity to work together — to design your next battery pack with optimized DoD settings that maximize lifetime without sacrificing performance or budget.