Quick take (30 seconds): Cells include passive safety features such as PTCs, CIDs and vent mechanisms that mitigate some abuse conditions. However, those passive elements alone cannot cope with system-level faults, misuse, or installation/transport failures. A properly designed battery pack must combine passive cell features with active pack-level protection (BMS, MOSFET switches, fuses and robust current sensing) to minimize risk of thermal runaway, leakage and hazardous failures.

1. Who should read this

This guide is written for procurement managers, system engineers, QA leads and technical buyers who need both the engineering rationale and an actionable factory checklist for safe battery procurement. It explains what cell-level passive protections do, where they fall short, the role of the Battery Management System (BMS), relevant standards and a practical factory inspection checklist you can use during sampling, acceptance and contract reviews.

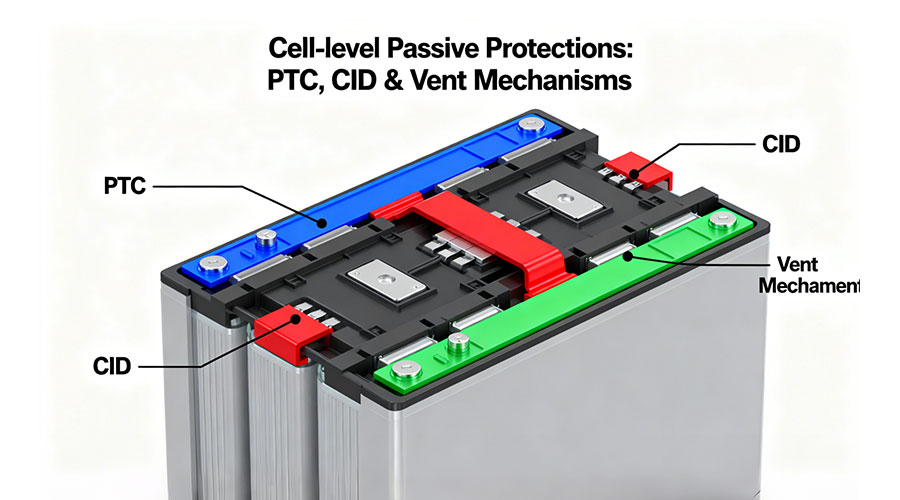

2. Cell-level passive protections: PTC, CID and venting

Most cylindrical and many pouch cells include passive safety elements integrated into the cell top cap or internal structure:

· PTC (Positive Temperature Coefficient) element: a resistive component whose resistance rises quickly with temperature. The PTC limits current during external short or overheating by increasing resistance as temperature climbs.

· CID (Current Interrupt Device): a mechanical/pressure-activated device that opens the cell’s electrical path when internal pressure or certain abuse thresholds are reached, allowing gas to vent and electrically isolating the cell.

These features are essential and reduce risk in many misuse scenarios. In production, manufacturers commonly record CID trigger pressures and PTC resistance curves for sampled cells — and these data sets are strong evidence to share with purchasers when negotiating quality agreements.

3. Why passive protection alone is insufficient

Passive elements react to internal events (heat or pressure) and can be slow or irreversible (for example, a CID may permanently open). They do not respond to many system-level failure modes such as:

· Faulty charger behavior or incorrect charge algorithm

· BMS firmware bugs or sensor failures

· External wiring short circuits, module interconnect faults or module-level heating due to poor thermal design

· Manufacturing or assembly defects in pack wiring, welded joints, or connectors

History and incident analyses show that many pack-level incidents involve combinations of factors—pack architecture, external abuse and operational errors—where cell internal safety alone could not prevent escalation. Hence the industry practice is “passive + active” protection: cell safety plus an intelligent BMS and robust protective hardware.

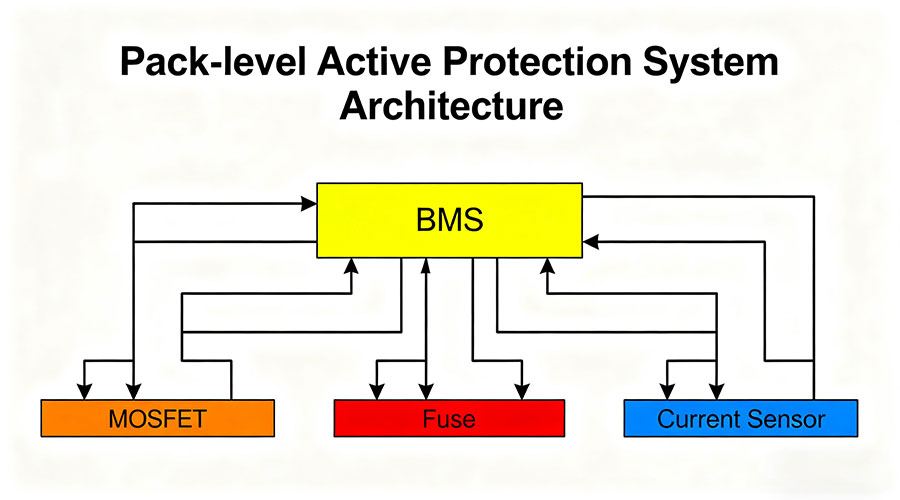

4. Pack-level active protections: what a BMS must do

A well-designed BMS is the active safety layer and typically provides:

· Per-cell voltage monitoring and cell balancing

· Pack current measurement (shunt or Hall sensor) for over-current and short-circuit detection

· Temperature sensing across the pack and thermal derating

· Charge and discharge cut-offs (over-voltage and under-voltage)

· Fast disconnect capability (MOSFETs, solid-state switches, or well-spec’d mechanical fuses)

· Event logging, fault codes and communication to higher-level controllers or telematics

Design best practices include redundant current sensing where the application is critical, Vds monitoring on MOSFETs to infer device health, and multi-path fail safes so that a single component failure cannot leave the pack unprotected.

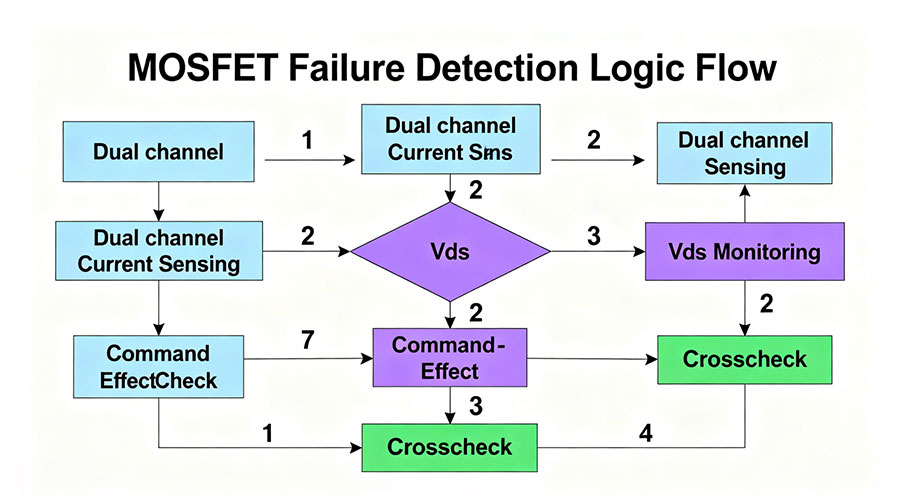

5. MOSFET failure modes and factory detection (our recommended practice)

MOSFETs perform switching and protection duties, but they can fail in ways that defeat the protection function (e.g., drain-source short, gate driver failure, solder joint crack). At factory test and in BMS logic we recommend:

· Dual current channels (redundant sensing): compare two independent current measurements; large discrepancies indicate sensor or path failure.

· Vds (drain-source voltage) monitoring: when MOSFET is commanded off, Vds should read near pack voltage; persistent low Vds when off indicates a shorted MOSFET.

· Command vs. effect cross-check: if the BMS issues a turn-off but the measured current or Vds doesn’t change as expected, log a fault and isolate the pack.

Including such detection logic in acceptance testing and in the BMS firmware increases field safety and reduces returns/recalls.

6. Standards you must know: IEC 62133 and UN 38.3

Two industry standards form the backbone of portable battery safety and transport:

· IEC 62133 (Part 2 for lithium systems): defines required safety tests for cells and batteries under reasonably foreseeable misuse and intended use, including overcharge, short circuit, mechanical and thermal abuse tests. Manufacturers commonly cite IEC 62133-2 certification for lithium packs.

· UN Manual of Tests and Criteria — Sub-section 38.3: mandatory transport tests for lithium cells and batteries (altitude, thermal, vibration, shock, external short circuit, overcharge/forced discharge, etc.). Passing UN 38.3 is normally required for air and many international ground/sea shipments. Recent revisions and clarifications make it important to request the version and test summary when reviewing supplier documents.

When you ask suppliers for “certificates,” always ask for the test report numbers and a test summary (test conditions, sample IDs and pass/fail criteria) — not only the “certificate” image.

7. Packaging and shipping: an often-overlooked source of incidents

A large share of battery failures during transit are caused by short circuits and poor packaging. Industry recommendations (and regulatory guidance) insist on:

· Terminal insulation (caps, tape, or segregated trays)

· No bare cells in the same box as metal objects

· Robust outer cartons and the correct hazard/UN labels when applicable

Empirical analyses indicate that a meaningful portion of transport incidents can be eliminated by strict packaging controls and training for logistics partners.

8. Practical factory inspection checklist (summary) — use this as a contract attachment

(Full checklist PDF is available for download; see link below.) Key items to include in your incoming or factory audit:

· Cell level sampling: CID trigger pressure distribution, PTC resistance vs temperature curves, cell IR and capacity at 25°C with statistics.

· Pack functional verification: BMS over/under voltage thresholds, over-current/short circuit trip behavior and timing, MOSFET operation checks, and sample discharge curves (0.2C to ~10% SOC).

· Safety abuse sample tests: controlled overcharge, external short test, mechanical and thermal abuse on representative samples with video and waveform evidence.

· Documentation & traceability: complete test data, raw waveforms, test equipment calibration records, and sample retention policy.

· Packaging & transport checks: terminal insulation, labeling, and UN 38.3 report for the lot.

You should write the checklist into the purchase/quality agreement as an annex so it becomes a contractual deliverable.

(Download the complete English factory checklist PDF at the bottom of this page.)

9. Quick procurement QA list — copy and paste for buyers

1. Do you have IEC 62133-2 test report numbers for this battery model?

2. Is there a UN 38.3 test summary available for the shipping lot?

3. Can the supplier provide CID top-cap pressure data and sampled PTC curves?

4. Does the BMS provide downloadable fault logs and event timestamps?

5. Are MOSFET/fuse operation test records available for the pack?

6. Are discharge curve samples (0.2C to cut-off) available for the production batch?

7. Is the packaging certified for transport (insulated terminals, correct labeling)?

8. Are hull/thermal abuse test videos or photos provided?

9. Is there a sample retention and failure analysis workflow?

10. Are pass/fail acceptance thresholds explicitly written in the T/C?

10. Real-world examples & lessons learned (anonymized)

We commonly see two recurring themes in returned/failed batches: (1) improper assembly/welds causing intermittent high resistance and local heating, and (2) incomplete BMS watch-dogs that fail to detect a gate driver or sense resistor failure. Contract clauses that require a small number of destructive or abuse tests on random samples — with video evidence — are highly effective at preventing repeat failures.

11. Conclusion — measurable, contractable safety

Turn the abstract requirement “meet IEC 62133/UN 38.3” into deliverables: provide test report numbers, raw data, CID/PTC distributions, BMS logs and the factory checklist signed by QA. That combination — passive cell safety plus active pack protections and contractual test evidence — is the practical way to reduce risk, lower after-sales costs and build buyer confidence.