Can a Battery Pack Be Repaired?

Batteries used in power tools, e-bikes, and other commercial devices can often be repaired by replacing one or multiple cells. For NiCd and NiMH battery packs, finding replacement cells is relatively easy. However, sourcing quality lithium-ion (Li-ion) cells is more difficult since top manufacturers usually sell only to certified assemblers and in bulk quantities. This creates challenges for smaller service shops trying to repair Li-ion battery packs.

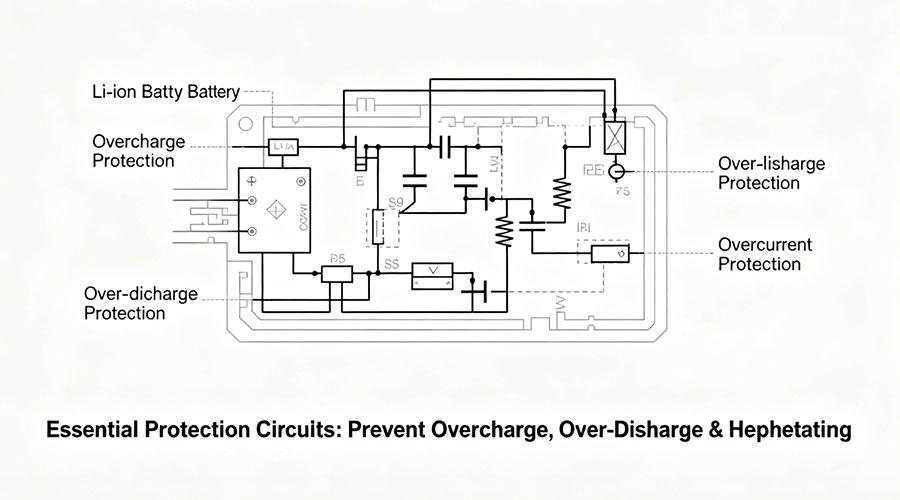

Why Protection Circuits Are Essential for Li-ion Packs

When repairing or rebuilding a Li-ion battery pack, always ensure the cells are properly connected to a protection circuit. Unlike lead-acid or nickel-based batteries, Li-ion batteries require protection circuits to prevent overcharge, over-discharge, and overheating. Without this safeguard, the repaired pack could become unstable or unsafe.

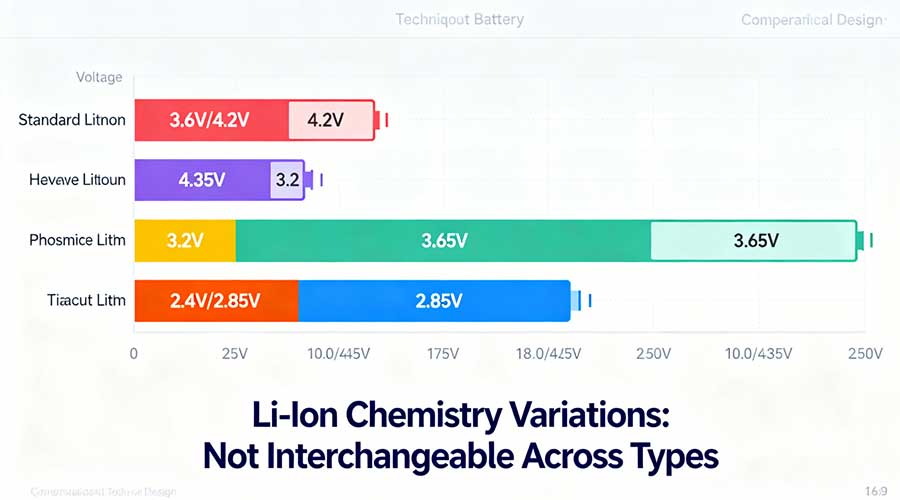

Differences Between Battery Chemistries

Lead-acid and nickel-based batteries are fairly uniform, but lithium-ion batteries come in many variations:

· Standard Li-ion: nominal 3.6V, full charge at 4.2V

· High-voltage Li-ion: charges up to 4.35V/cell

· Li-phosphate (LiFePO₄): nominal 3.2V, charge limit 3.65V

· Li-titanate: nominal 2.4V, charge limit 2.85V

Because of these differences, Li-ion cells are not interchangeable across chemistries. Using the wrong type could damage the pack or make it unsafe.

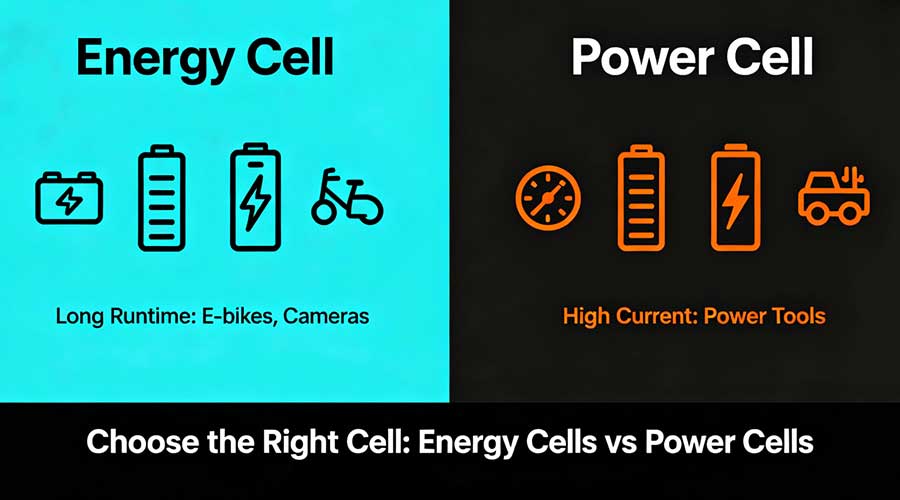

Choosing the Right Cells for Battery Pack Repair

Li-ion batteries can generally be grouped into two categories:

· Energy Cells – optimized for longer runtime, used in devices like e-bikes, cameras, and communication devices.

· Power Cells – optimized for high current output, used in power tools.

When replacing cells in a power tool battery pack, always use Power Cells of the same specification to maintain strength and performance. Mixing cell types or using cheap alternatives from unreliable sources may lead to premature failure within 2–3 years.

Should You Replace One Cell or All Cells?

If a relatively new pack has just one defective cell, replacing it can make sense. However, with an older pack, it is best to replace all cells at once. Mixing new and old cells often causes imbalance, shortening the overall lifespan. In a well-matched battery pack, all cells should have similar capacity, resistance, and performance.

Matching and Testing Replacement Cells

Cells designed for multi-cell packs must meet tighter tolerances compared to single-cell use. Before reusing or replacing cells, test them for the following health indicators:

· Capacity – ability to store energy.

· Internal resistance – affects how much current the cell can deliver.

· Self-discharge – indicates hidden defects or stress damage.

When salvaging cells from another pack, always check, label, and match them with cells of similar performance to avoid mismatch problems.

NiCd vs. NiMH Replacement Compatibility

Many users wonder if NiCd packs can be rebuilt with NiMH cells. In theory, this is possible because both chemistries share the same nominal voltage. However, their charging requirements differ. NiMH uses a more refined charge algorithm, while older NiCd chargers may overcharge NiMH due to improper detection. For safety and performance, always use the correct charger designed for the specific chemistry.

Proper Techniques for Rebuilding Battery Packs

The most reliable way to assemble a battery pack is through spot-welding. Four spot welds per cell is the industry norm, ensuring strong and low-resistance connections. Some safety and performance guidelines include:

· Limit heat transfer during welding to avoid damaging cells.

· Electrically insulate each cell since the casing is often “live.”

· If cells are at different charge levels, apply a slow charge to equalize them.

· Monitor temperature during charging — Li-ion should remain cool, while nickel-based cells will warm up slightly near full charge.

Post-Repair Testing of Battery Packs

After repairing a battery pack:

· Measure pack voltage immediately, then again after 24 hours and a few days.

· Check for abnormal voltage drops, which may indicate high self-discharge in one or more cells.

· Ensure all cells charge and discharge evenly; uneven heating or voltage drift signals a defect.

Key Safety Guidelines for Battery Pack Repair

· Only use matched cells; do not mix chemistry, capacity, or age.

· Never operate or charge Li-ion batteries without a working protection circuit.

· Always include a temperature sensor to prevent overheating.

· Apply a slow charge after repair to balance cell voltage levels.

· Avoid unrecognized or low-quality cell brands; they often fail prematurely.

· Do not attempt to repair batteries that are physically damaged, swollen, or deeply discharged below 1.5V/cell.

Repairing a battery pack is possible and cost-effective if done correctly. By choosing quality cells, ensuring proper protection circuits, and following safe repair practices, you can restore performance and extend the lifespan of power tool batteries, e-bike batteries, and other rechargeable packs.