In today’s fast-evolving battery landscape, transparency isn’t just a buzzword—it’s a business imperative. The European Union’s upcoming Battery Passport regulation will reshape how manufacturers, suppliers, and end-users interact with battery products throughout their life cycle. In this article, we’ll break down what the Battery Passport is, why it matters for manufacturers, and how your factory can get ahead of the curve—even if you’ve never tackled digital traceability before.

Why the Battery Passport Matters

Come February 1, 2027, the EU will require all industrial and electric-vehicle battery packs over 2 kWh to carry a unique Battery Passport. Think of it as a QR code (or NFC tag) that unlocks:

· Materials & Chemistry: From active materials to binder agents

· Carbon Footprint: Precise CO₂-equivalent emissions for each pack

· Performance Metrics: Cycle life, warranty data, manufacturing date

· Supply–Chain Transparency: Proof of ethical sourcing and conflict-mineral compliance

For manufacturers, this isn’t just compliance red tape. A clear, verifiable Battery Passport:

· Builds Trust with OEMs and end-users who demand proof of origin and performance

· Streamlines Recycling by giving recyclers accurate end-of-life data, boosting circular-economy credentials

· Differentiates Your Brand in a crowded market, showcasing your commitment to sustainability and quality

What Information You’ll Need to Collect

To assemble a compliant Battery Passport, your factory must capture and manage several data categories:

1. Raw Material Batches

O Supplier name, lot number, date received

2. Cell & Pack Assembly

o Cell model, configuration, assembly date, quality-control test results

3. Performance Testing

o Capacity validation, cycle-life test logs, thermal-runaway simulations

4. Carbon Footprint Calculation

o Emissions from raw materials, energy used in production, transportation data

5. Regulatory Certifications

o UN 38.3, IEC 62133, CE declarations

Pro Tip: Align these data points with your existing MES (Manufacturing Execution System) or ERP modules. If you’re still using paper logs or siloed spreadsheets, now’s the time to invest in digital forms and automated data capture.

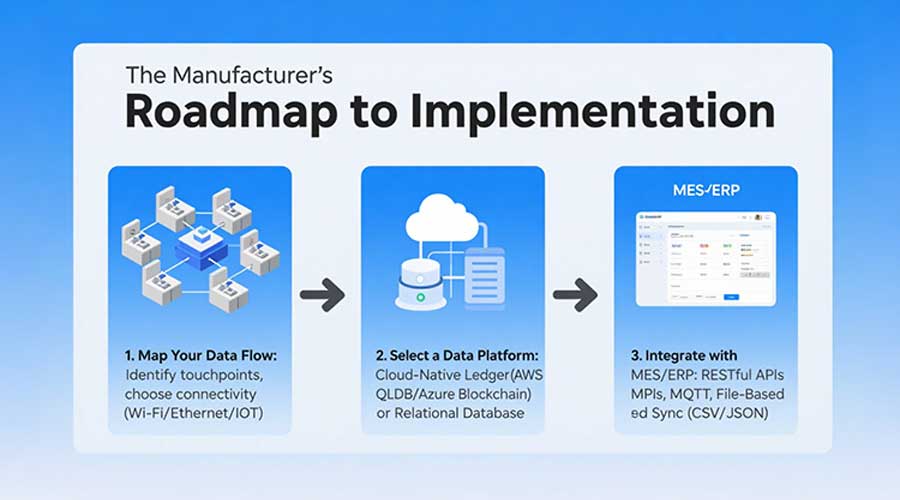

The Manufacturer’s Roadmap to Implementation

1. Map Your Data Flow

· Identify Touchpoints: Every station—mixing, coating, assembly, testing—must feed data into a central system.

·Choose Your Connectivity: Wi-Fi, Ethernet, or lightweight IoT gateways (e.g., MQTT-enabled devices) ensure real-time data transfer.

2. Select a Data Platform

You have two main paths:

· Cloud–Native Ledger (e.g., AWS QLDB, Azure Blockchain) for immutable audit trails

· Relational Database with strong access controls, versioning, and audit-log plugins

Whichever you pick, plan for scalability—today’s pilot becomes tomorrow’s full-line rollout.

3. Integrate with MES/ERP

· RESTful APIs are often easiest to implement and maintain

· MQTT works well for high-frequency sensor data (like temperature or humidity)

· File–Based Sync (CSV/JSON exports) can bridge legacy systems

Your goal: when a cell is stamped “OK” in production, that event—and all its metadata—flows automatically into the Battery Passport database.

EU Commission – Batteries Regulation & Battery Passport

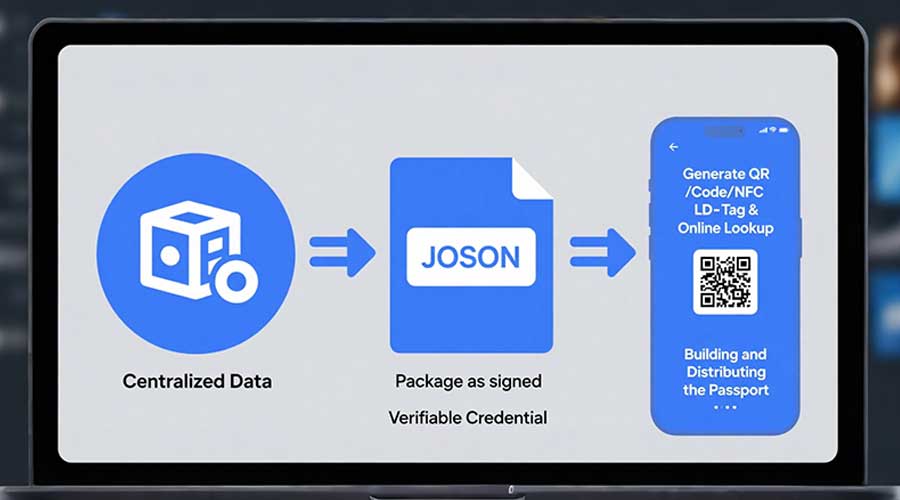

Building and Distributing the Passport

Once data is centralized, you need to:

1. Package the Passport as a signed JSON-LD or Verifiable Credential

2. Generate a QR Code/NFC Tag linked to that credential

3. Provide an Online Lookup: Simple web page or mobile app where OEMs and recyclers scan and view full battery history

Security Note: Employ digital signatures (PKI) to prevent tampering, and enforce HTTPS on all APIs.

Turning Compliance into Competitive Advantage

By embracing the Battery Passport now, you:

· Demonstrate Leadership in sustainability and traceability

· Expand Market Access into buyers who insist on full-chain transparency

· Reduce Risk of costly recalls or fines for non-compliance

At Himax Battery, our turnkey solutions help you integrate data capture hardware, cloud infrastructure, and front-end passport display—so you can focus on making the highest-quality cells and packs.

Ready to make your factory a pioneer in digital battery traceability? Contact our team for a free consultation and see how we can customize a Battery Passport implementation that fits your production flow.