At Himax, we understand that every robot has unique power demands. Whether you’re building automated guided vehicles (AGVs), service robots, or industrial robots, the battery that powers these systems must be tailored to your specific needs. We specialize in offering custom robot battery solutions with a focus on the battery management system (BMS) and ensuring that every step of the design, testing, and production process meets industry standards. Below, we’ll walk you through our customization process, testing services, and the advantages of working with Himax for all your robot battery needs.

1. Consultation & Requirements Definition

The first step in creating the perfect robot battery is understanding the specific needs of the application. At Himax, we work closely with our customers during the early stages of the project to define the battery management system (BMS) specifications and the hardware/software requirements.

Our Process:

· In-depth Consultation: Our engineers collaborate with clients to analyze the working conditions of the robot—voltage, current, environmental factors like temperature and humidity, and specific power demands (e.g., high discharge rates, long operational times).

· BMS Specification Document: Based on this consultation, we provide a detailed BMS requirement document outlining the electrical and thermal management needs, battery protection strategies, and integration points with the robot’s existing systems. This document serves as the blueprint for the battery pack design, ensuring that all specifications are aligned with the project’s goals.

· Technical Support & Advice: Our team provides insights into battery types (such as LiFePO₄, Li-ion), BMS architecture, and system integration to optimize the design for performance, safety, and efficiency.

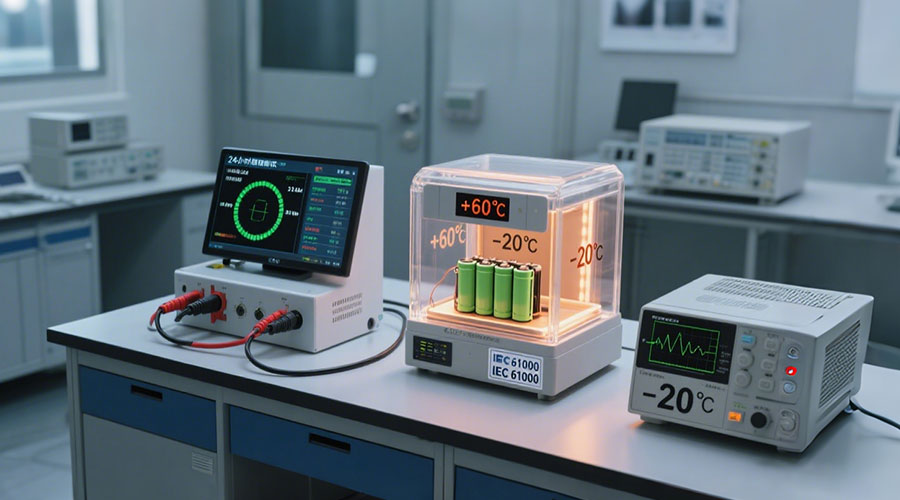

2. Prototype Development & Laboratory Testing

Once we have agreed on the design, we move to the prototype phase, where we develop the first batch of robot batteries for testing. Our in-house laboratory is equipped to carry out rigorous tests to ensure that the prototype performs under real-world conditions.

Testing Services:

· 24-Hour Cycle Testing: We run continuous charge and discharge tests to simulate long-term use, verifying the cycle life and overall performance of the robot battery. This test also helps detect any potential issues early in the process.

· High & Low Temperature Testing: Our lab conducts tests at both high (+60°C) and low (–20°C) temperatures to ensure that the robot battery can handle extreme conditions without performance degradation or safety risks.

· Electromagnetic Compatibility (EMC) Testing: To ensure the BMS and robot battery function without interference, we test the system’s resilience to electromagnetic interference (EMI), ensuring it meets industry standards like IEC 61000.

Certifications & Standards:

· We ensure that all our prototypes meet UL 2056 (for portable power packs) and IEC 62619 (for industrial rechargeable batteries) certifications. UL Solutions Battery Module and Pack Testing

3. Scaling Up to Mass Production

Once the prototype has been successfully tested, Himax helps clients move from the pilot run to full-scale production. Our ability to support both small batch testing and large-scale manufacturing ensures that the robot battery can be delivered reliably at the required volume and quality.

Our Mass Production Process:

· Small Batch Production: We begin with small batch runs (100 to 500 units) to validate the design and address any last-minute issues before full-scale manufacturing begins.

· Quality Control:

o Incoming Quality Control (IQC): We carefully inspect all materials and components to ensure they meet specifications before production begins.

o In-Process Quality Control (IPQC): Throughout the production process, we perform regular checks to guarantee that every step of assembly is in line with industry standards.

o Outgoing Quality Control (OQC): Before shipping, every robot battery undergoes a final inspection, ensuring it passes all safety tests and performance requirements.

· Supply Chain Assurance: Himax partners with top suppliers of raw materials, ensuring consistent availability and timely delivery of components, so you never experience supply chain disruptions.

After-Sales Support:

· Warranty & Maintenance: Himax offers comprehensive after-sales support, including product warranties, preventive maintenance schedules, and technical troubleshooting.

· Software Updates & Optimization: We provide ongoing support for BMS software updates, ensuring your robot battery stays optimized for performance throughout its life cycle.

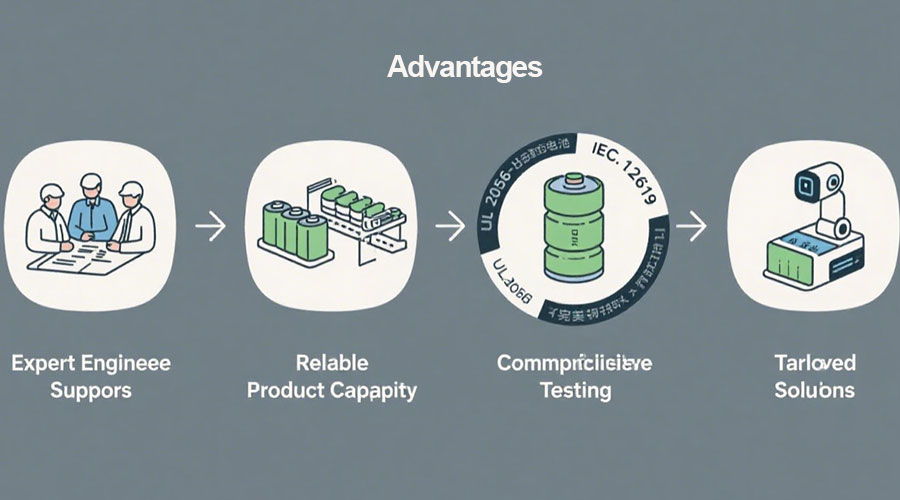

4. Why Choose Himax for Your Custom Robot Battery Needs?

Tailored Solutions:

Himax provides complete customized robot battery solutions from design to delivery, ensuring the battery packs meet all the safety, performance, and environmental requirements specific to your application.

Expert Engineering Support:

Our team of experienced engineers assists you throughout the process—from initial consultations to prototype development, testing, and scaling up to mass production. We ensure that every detail is covered, providing the highest quality product possible.

Reliable Production Capacity:

With our in-house capabilities, we support both small batch testing and large-scale production. Whether you’re making 100 units or 100,000, we guarantee consistent quality, timely delivery, and reliable performance.

Comprehensive Testing and Compliance:

Our laboratory testing, along with certifications from UL and IEC, ensures that every robot battery meets global standards. We conduct extensive thermal, electrical, and mechanical testing to confirm each battery is up to the task.

Get Started with Himax Today

At Himax, we believe in providing customized robot battery solutions that not only meet but exceed our clients’ expectations. Our comprehensive testing, quality control processes, and engineering support ensure that your batteries are safe, durable, and ready for deployment in any industrial or robotic application.

Contact Himax today to learn more about our custom robot battery solutions and start your project with us!