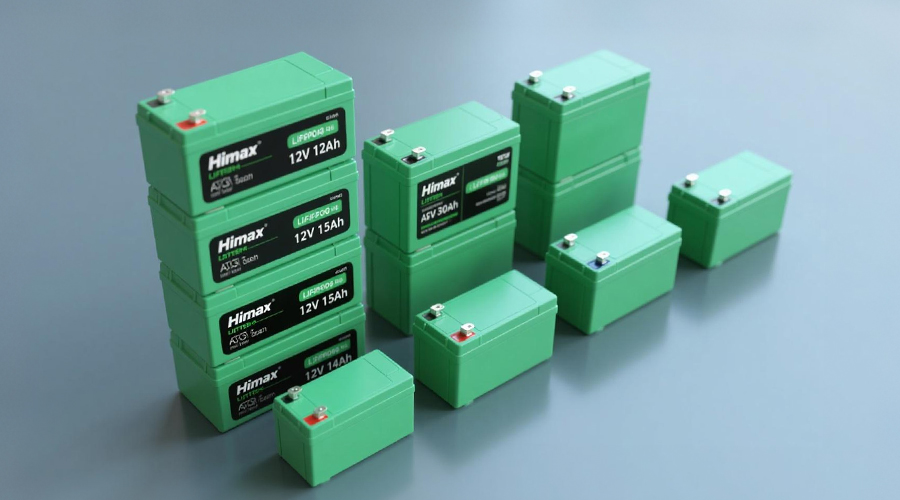

Power Your Compact Projects with 12 V LiFePO₄: Small Packs, Big Benefits

Whether you’re equipping telecom backup racks, outfitting portable medical carts, or keeping security panels online, a reliable 12 V LiFePO₄ battery and matching 12 V LiFePO₄ battery charger make all the difference. In this guide, we’ll walk you through why LiFePO₄ battery 12 V packs in the 6 Ah–30 Ah range are the ideal choice for B2B applications—and how to pick, integrate, and maintain them for years of trouble free service.

1. Your Next Compact Power Solution

Imagine your engineering team fitting a 6 Ah LiFePO₄ module into a slim telecom UPS, or your operations manager swapping out a 30 Ah pack in a security kiosk between shifts—no lead acid slurry, no surprise downtime. That’s the everyday advantage of a 12 V LiFePO₄ battery: small size, light weight, and rock solid performance.

2. Why 12 V LiFePO₄ Rules for Small Capacity

· Space & Weight Savings

Compared to lead acid cells, LiFePO₄ chemistry cuts weight by nearly half. A 12 Ah pack can weigh under 2 kg—a game changer when every gram counts.

· Inherent Safety

LiFePO₄’s stable crystal structure resists thermal runaway. In sensitive environments—medical carts, remote IoT nodes—you get peace of mind alongside performance.

· Long Lifecycle & Lower TCO

Expect over 2,000 charge cycles with minimal capacity fade. Fewer replacements mean lower lifecycle costs and simplified inventory planning.

3. Three Key Benefits for Your Workflow

1. Consistent Voltage Output

From first to last cycle, your devices see a steady 12 V rail—no brownouts, no performance dips.

2. Fast, Smart Charging

A dedicated 12 V LiFePO₄ battery charger balances cells and optimizes charge time, typically delivering a full charge in 3–5 hours at the correct current.

3. Built In BMS Protection

Integrated BMS safeguards against overcharge, over discharge, short circuits, and extreme temperatures—reducing field failures and service calls.

4. Small Capacity LiFePO₄ Specs at a Glance

| Capacity | Dimensions (L×W×H) | Weight | Cycle Life | Charger Current |

| 6 Ah | 150×65×95 mm | ~0.9 kg | ≥ 2,000 | 1–2 A |

| 8 Ah | 151×65×100 mm | ~1.1 kg | ≥ 2,000 | 1–2 A |

| 12 Ah | 151×98×98 mm | ~1.8 kg | ≥ 2,000 | 2 A |

| 20 Ah | 181×77×167 mm | ~3.0 kg | ≥ 2,000 | 3–5 A |

| 24 Ah | 181×76×167 mm | ~3.5 kg | ≥ 2,000 | 5 A |

| 30 Ah | 260×168×208 mm | ~5.5 kg | ≥ 2,000 | 5–8 A |

Pro Tip: For maximum longevity, charge at ≤ 0.5 C. For example, pair a 12 Ah pack with a 5 A charger to balance speed and cycle life.

5. Four B2B Use Cases

1. Telecom Backup Systems

o Needs: Compact UPS modules; occasional power holds through outages.

o Solution: 6–12 Ah packs with reliable standby voltage.

2. Portable Medical Equipment

o Needs: Quick recharge between procedures; strict safety standards.

o Solution: 8–12 Ah modules with medical grade BMS and fast charge capability.

3. Security & Alarm Panels

o Needs: Consistent backup power for sensors and comms; infrequent maintenance windows.

o Solution: 12–20 Ah packs rated for thousands of cycles under trickle loads.

4. Remote IoT & Edge Devices

o Needs: Solar charged nodes or off grid sensors; wide temperature operation.

o Solution: 20–30 Ah packs with solar compatible charge profiles and –20 °C to +60 °C rating.

6. Selecting the Right 12 V LiFePO₄ Charger

·Dedicated vs. Generic

Only a purpose built 12 V LiFePO₄ battery charger delivers the correct end of charge cutoff and cell balancing. Generic lead acid chargers risk under or over charging.

·Ideal Charge Rate

Aim for 0.2–0.5 C (e.g., 4 A for 20 Ah) to optimize both turnaround time and cycle life.

·Must Have Features

o LED/ LCD charge status indicators

o Temperature compensation

o Short circuit and reverse polarity protection

o Universal AC input (100–240 VAC) for global deployment

7. Integration & Deployment Best Practices

1. Mechanical Mounting

Use vibration damping brackets or standard DIN rail trays; secure connectors to the torque specs.

2. Electrical Hookup

Choose Anderson, IEC, or custom connectors rated beyond your peak current; verify wiring insulation and strain relief.

3. BMS Configuration

Set your over /under voltage thresholds and enable telemetry (CAN, RS485) if remote monitoring is needed.

8. Maintenance & End of Life Strategies

·Routine Health Checks

Monthly voltage spot checks and quarterly internal resistance tests help forecast end of life and schedule replacements.

·Proper Storage

Store packs at 40–60% state of charge in a cool, dry environment. Check every three months and top up as needed.

·Recycling & Trade In

Partner with certified recyclers or explore trade in credits on volume orders to recover residual value and reduce waste.

9. B2B FAQ Corner

1. Can I parallel different Ah ratings?

Yes—with caution: parallel only identical voltage and cell chemistry packs, and balance their state of charge before connecting.

2. What’s the lead time for 1,000 units?

Typical turnaround is 6–8 weeks after order confirmation; expedited options may be available.

3. Do you offer custom form factors or branding?

Absolutely—our engineering team can tailor dimensions, labels, and connectors to your specifications.

4. How are international warranties handled?

We provide regional service hubs, remote diagnostics, and advance replacement programs to minimize your downtime.

10. Take the Next Step

Ready to see how a 12 V LiFePO₄ battery and charger can streamline your operations?

· Request Samples: Trial 6–30 Ah packs in your setup before committing.

· Get a Customized Quote: Share your application details for optimized pack and charger bundles.

· Consult Our Engineers: From BMS firmware tweaks to mechanical integration, we’re here to help.

Contact HimaxBattery.com today and power your projects with confidence.