Detecting a failing LiFePO₄ battery early can save you both downtime and replacement costs. In this post, you’ll learn exactly how to tell if a LiFePO₄ battery is bad by spotting five key signs before they lead to complete failure.

Whether you’re running solar storage systems, EV fleets, or golf cart fleets, maintaining LiFePO₄ battery health is essential for reliable performance. We’ll cover the warning signals, root causes, quick diagnostic tests, and best practices to keep your battery bank in peak condition.

How to Tell if a LiFePO₄ Battery Is Bad: 5 Key Signs

1. Voltage Irregularities

A healthy LiFePO₄ cell rests at 3.2–3.4 V. If you measure below 3.0 V or above 3.6 V per cell, that’s a red flag. Under load, a sudden voltage sag—dropping more than 0.1 V under light draw—signals increased internal resistance and early failure.

2. Capacity Loss & Rapid Discharge

When your pack delivers significantly less amp-hours than rated, you’re seeing capacity loss. If runtime falls below 80 % of the spec or the battery “dies” quickly under normal load, that indicates a worn-out cell.

3. Excessive Heat Generation

LiFePO₄ chemistry tolerates up to 60 °C briefly, but continual operation above 45 °C accelerates degradation. Use an infrared gun or thermal imaging to spot hot spots—uneven heating points to internal shorts or cell imbalance.

4. Physical Deformation

Swelling, bulging, or cracked cases are obvious. Inspect the pack housing for swelling at regular intervals, and check terminals for corrosion. Physical damage often stems from overpressure or internal gas buildup.

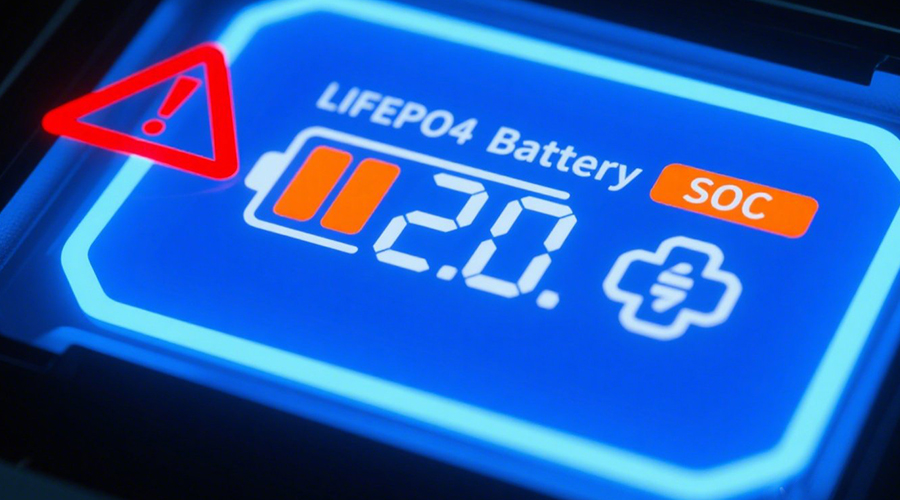

5. BMS Fault Alerts & Error Codes

Your battery management system (BMS) should log cell imbalance, overcurrent, or overvoltage faults. Recurring alarms, communication dropouts, or forced shutdowns are clear signs the pack isn’t safe to operate.

Common Causes of LiFePO₄ Battery Damage

Over-discharge Beyond Safe Depth of Discharge (DoD)

Draining below 10 % SOC stresses cells. Repeated deep discharges shorten cycle life dramatically.

Improper Charging Profile

Using a charger set for lead-acid or wrong voltage cut-offs prevents a full balance charge, leading to persistent cell mismatch.

Extreme Temperature Exposure

Operating in sub-zero or high-heat environments without thermal control causes permanent capacity loss.

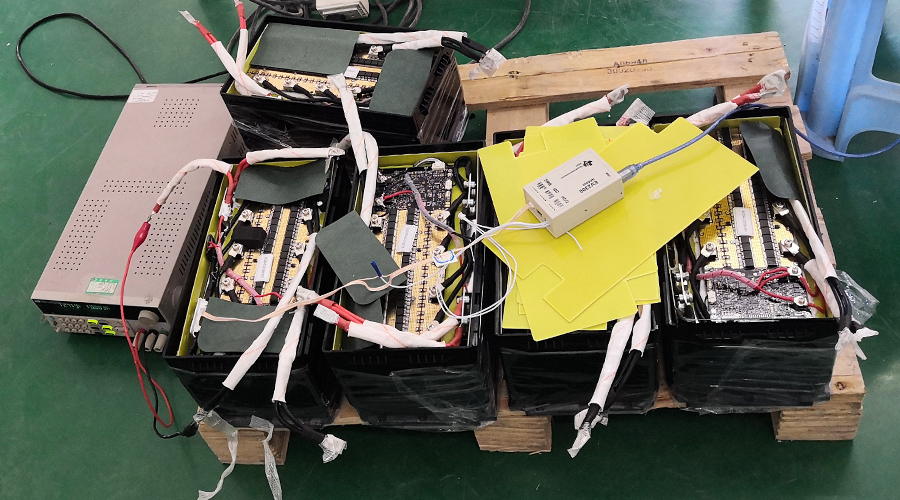

Cell Imbalance & Inadequate Equalization

Without periodic balancing, some cells carry more load than others, triggering early failure in the weakest cells.

BMS Malfunction or Poor Integration

A misconfigured BMS won’t protect cells correctly. Loose sense wires, firmware bugs, or wrong thresholds all lead to undetected faults.

How to Test Your LiFePO₄ Battery Health

Multimeter Voltage Check

Measure resting voltage after 24 hours off-charge. Cross-check under light load to confirm internal resistance is within spec.

Capacity & Load Test

Discharge at a known current and record the time to cut-off. Compare delivered amp-hours to the rated capacity.

Internal Resistance Measurement

Use an impedance tester or smart charger with IR test. Elevated internal resistance (>1 mΩ per cell) means aging cells.

Thermal Imaging Inspection

Scan the pack under load using an IR camera. Any cell running >5 °C hotter than its neighbors is at risk.

BMS Diagnostics & Data Log Review

Download event logs to spot repeated over-current, under/over-voltage or temperature warnings.

When to Replace Your LiFePO₄ Battery

· Cycle Life Threshold: Pack capacity falls below 80 % after rated cycles (e.g. 2,500 cycles).

· Persistent BMS Faults: Errors continue after recalibration or repair.

· Capacity < 70 % of Rated Ah: Even after a full conditioning cycle.

Maintenance Tips to Extend LiFePO₄ Battery Life

Use a Dedicated LiFePO₄ Smart Charger

A charger with proper constant-current/constant-voltage profile and end-of-charge detection protects cells from overvoltage.

Maintain Ambient Temperature (20–25 °C)

Store and operate within this range for optimal battery lifespan optimization.

Perform Periodic BMS Balancing

Schedule balance cycles every 30–60 days to keep each cell at equal SOC.

Store at 50 % State-of-Charge for Long Periods

Long-term storage at 4.0 V pack voltage (≈50 % SOC) minimizes stress and self-discharge.

Keep Terminals Clean and Connections Tight

Corrosion or loose lugs increase resistance and heat, accelerating wear.

Conclusion & Next Steps

Early detection is the key to battery care for LiFePO₄ systems. By watching for these five signs, diagnosing faults, and following proactive maintenance, you’ll maximize uptime and ROI.

Ready to upgrade your LiFePO₄ battery solution? Contact Himax Battery for factory-direct packs, custom BMS integration, and full technical support tailored to your fleet or solar installation.

FAQ

Can a bad LiFePO₄ cell be reconditioned?

Minor voltage sag can sometimes be reversed via controlled balance charging, but physical damage or high internal resistance cells must be replaced.

How often should I run a balance cycle?

Every 30–60 days under normal use, or immediately after noticing voltage drift during a capacity test.

What’s the ideal storage SOC for LiFePO₄?

Store at 3.35 V per cell (≈50 % SOC) to minimize stress and slow self-discharge.