Industrial water pumps play a critical role in factories, warehouses, farms, construction zones, and municipal systems. When the power goes out, these pumps must continue running to prevent downtime, equipment damage, and even safety hazards. That is why selecting the right backup battery system is essential for maintaining operational reliability. This guide explains how to evaluate and choose backup batteries for industrial water pumps, with a focus on understanding performance requirements, environmental considerations, and long-term reliability.

Understanding Why Industrial Pumps Need a Backup Battery

Industrial water pumps often move large volumes of water in critical applications. Any unexpected shutdown can cause serious problems. Power failures may result from severe weather, grid instability, equipment malfunction, or scheduled maintenance. A battery backup system provides instant emergency power so the pump can keep operating until the main supply returns.

In industrial settings, even a few minutes of downtime can cause flooding, stalled production, or contamination risks. If the pump supports cooling systems, a power loss could cause machinery to overheat. If it handles wastewater, failure could lead to environmental hazards. Because of this, facilities increasingly rely on a dependable Sump Pump Battery Backup or other industrial-grade battery solutions.

Identify the Type of Pump and Its Power Requirements

Before selecting a battery, you must know the pump’s electrical specifications. Industrial water pumps vary widely in size and function, and each model demands a specific amount of power. Look for the following information on the pump label or user manual:

- Rated voltage (commonly 12V, 24V, or 48V DC for battery-driven systems)

- Running amperage

- Starting amperage (often significantly higher)

- Motor type (AC motor, DC motor, or inverter-driven)

Many pumps have a high surge current when starting up. Your battery backup pack must supply enough initial power without dropping voltage. Choosing a battery with insufficient peak output can result in the pump failing to start at all.

For larger industrial systems, you may also need an inverter capable of converting battery DC power to AC. In this case, ensure the inverter is surge-rated to match the pump’s startup load. Proper sizing protects both the pump and the backup system.

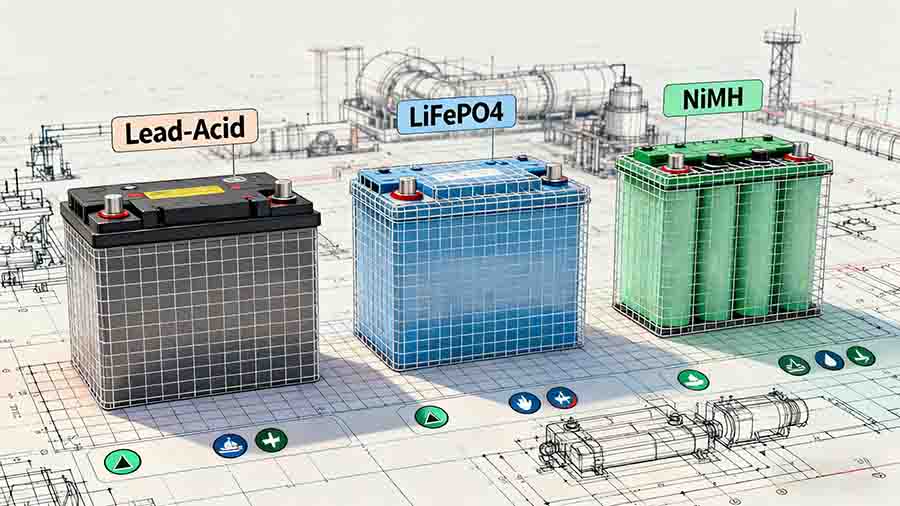

Choose the Right Battery Chemistry for Industrial Applications

Battery chemistry plays a huge role in performance, lifespan, and safety. Several types are commonly used in industrial backup systems:

Deep-Cycle Lead-Acid Batteries

These are affordable and widely used in backup power applications. Their advantages include predictable performance and strong surge current. However, flooded lead-acid types require maintenance, while AGM batteries offer maintenance-free operation. They tend to be heavy and may have shorter life under high-cycle conditions.

Lithium Iron Phosphate (LiFePO4) Batteries

LiFePO4 batteries are becoming the preferred choice for many industrial teams. They offer longer lifespan, lighter weight, and stable performance in demanding conditions. They can deliver high continuous power and recharge quickly. They are ideal for modern Sump Pump Battery Backup applications where reliability and efficiency matter.

Nickel-Metal Hydride (NiMH) Batteries

NiMH batteries are less common in pump systems but may be used in specialized applications requiring moderate capacity and long cycle life.

When selecting the best chemistry, consider whether the pump must run for long durations, operate in harsh environments, or require rapid recharging. For most heavy-duty industrial uses, LiFePO4 deep-cycle batteries provide superior long-term value.

Calculate Battery Capacity and Runtime Requirements

To choose the correct battery size, you must understand how long the pump needs to run during an outage. Some industries require only a few minutes of operation; others may need several hours of backup runtime.

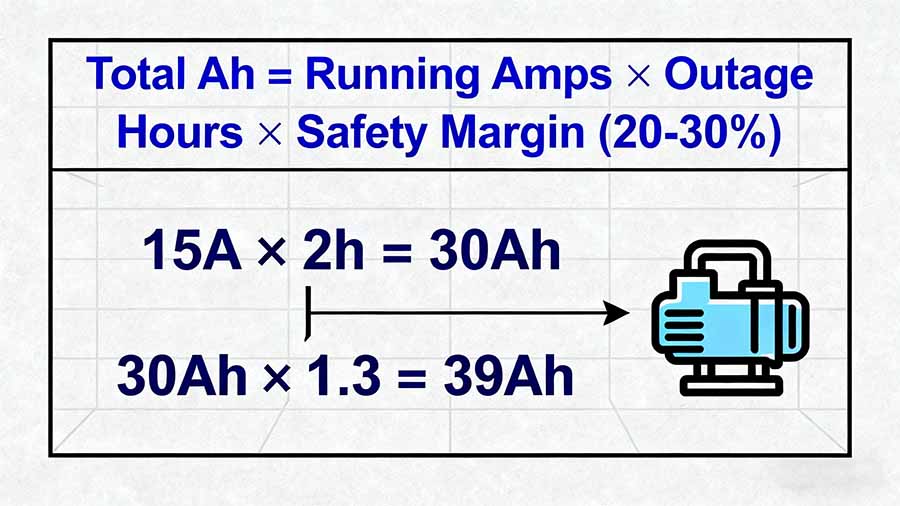

A simple way to estimate capacity:

- Identify the pump’s power consumption (watts or amps).

- Determine the expected outage duration.

- Add a safety margin of 20%–30%.

For example, if a pump consumes 15 amps at 24 volts and must run for two hours:

- Total amp-hours needed = 15A × 2h = 30Ah

- With a 30% margin: 30Ah × 1.3 = 39Ah

This means you should select a battery of at least 40Ah capacity. Industrial systems often need much higher capacity and may require multiple batteries connected in parallel to extend runtime.

Having accurate calculations prevents underperforming systems and ensures the pump stays operational throughout an outage.

Consider Environmental and Operating Conditions

Industrial environments vary widely. The backup battery must withstand temperature swings, moisture, vibration, and other harsh conditions.

Consider the following factors:

- Temperature Range: Some batteries—especially lead-acid—lose capacity in cold temperatures.

- Moisture & Humidity: Pumps often operate in wet environments, so batteries should be sealed or placed in protective enclosures.

- Vibration Resistance: Industrial sites may expose batteries to continuous vibration from machinery.

- Space Constraints: The chosen battery must physically fit in the pump’s installation area.

A rugged industrial backup power solution is crucial for long-term reliability. Batteries designed for marine, solar, or off-grid power applications often perform well in pump environments.

Evaluate Safety, Monitoring, and Maintenance Needs

Safety is a major concern when selecting backup batteries. Look for:

- Overcurrent and short-circuit protection

- Thermal management systems

- Overcharge and deep discharge protection

- Built-in battery management systems (BMS) for lithium batteries

A Sump Pump Battery Backup with a smart BMS provides status monitoring, balancing, temperature control, and diagnostic alerts. This helps extend battery life and reduces maintenance time.

For lead-acid batteries, regular inspections for corrosion, water levels (if applicable), and voltage drop are necessary. Lithium batteries require far less maintenance.

Plan for Installation, Expansion, and Replacement Cycles

A backup system for industrial water pumps should be designed with future scalability in mind. Consider whether the facility may upgrade to larger pumps, extend runtime needs, or add additional support systems.

Your installation plan should factor in:

- Space for additional batteries

- Compatible voltage configurations

- Accessible wiring and connections

- Cooling or ventilation if required

Regular battery replacement planning also matters. Lead-acid batteries may last 2–4 years, while LiFePO4 batteries often last 8–12 years or more. Long lifecycle batteries reduce downtime and long-term cost.

Why a Well-Designed Battery Backup System Matters

A reliable battery backup system ensures continuous water flow, protects equipment, and keeps the facility safe. It eliminates the risk of flooding, overheating, system failures, and costly downtime. Investing in a robust solution reduces long-term risks and provides peace of mind for facility managers and maintenance teams.

As industries become more automated, the need for dependable backup power will continue to grow. Selecting a high-quality backup battery is one of the most effective ways to ensure pump systems remain operational under any condition.

HiMAX Sump Pump Battery Backup Introduction

HiMAX offers premium Sump Pump Battery Backup solutions designed for industrial reliability. Our deep-cycle LiFePO4 battery systems provide long lifespan, fast charging, stable power delivery, and superior safety protection. HiMAX batteries are engineered for high surge output, making them ideal for pumps that require strong startup currents. With built-in smart BMS control, durable housings, and customizable voltage and capacity options, HiMAX delivers dependable emergency power for factories, warehouses, commercial buildings, and water management facilities. If you need a powerful, maintenance-friendly, and long-lasting backup battery for your industrial pump system, HiMAX provides a solution you can trust.

Find articles related to Sump Pump Battery