Self-discharge is a natural behavior in all batteries—energy slowly decreases even when the battery is not connected to any load. For consumer electronics, robotics, backup systems, and long-storage applications, the self-discharge rate plays a significant role in product reliability, user experience, and the total cost of ownership.

However, when the self-discharge rate becomes higher than normal, it may indicate internal issues or improper storage conditions. This article explains what “elevated self-discharge” means, what causes it, how it affects battery performance and safety, and how Himax Battery prevents it through production and quality control.

What Is Elevated Self-Discharge—and Why It Matters

Elevated self-discharge refers to a condition where a battery loses charge faster than expected while resting. Although self-discharge is normal, excessive levels usually point to internal abnormalities such as contamination, micro-shorts, material degradation, or mechanical damage.

In severe cases, elevated self-discharge may be an early sign of internal short circuits, localized heating, or chemical instability—all of which must be taken seriously.

How Different Battery Chemistries Behave

Self-discharge varies by chemistry:

·NiMH / NiCd: Higher natural self-discharge and steeper drop in the first days after charging.

·Lead-acid: Moderate self-discharge but sensitive to high temperature.

·Lithium-ion: Relatively low self-discharge (often 1–2% per month), though influenced by temperature, aging, and the BMS standby current.

For lithium-ion batteries, this makes proper storage voltage and temperature extremely important.

Temperature and State of Charge (SoC)

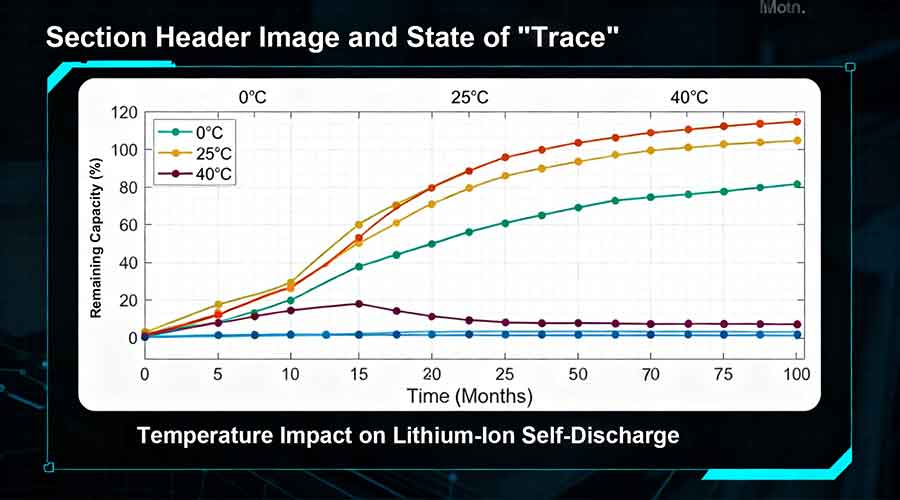

Temperature

Self-discharge increases rapidly as temperature rises. A common engineering guideline is that self-discharge roughly doubles for every 10°C increase.

Storing batteries in hot environments—such as cars, warehouses without ventilation, or near heat sources—significantly accelerates charge loss and aging.

State of Charge

·High SoC (close to 100%) increases self-discharge and accelerates aging.

·Mid-level SoC (30–60%) is ideal for long-term storage.

Common Causes of Elevated Self-Discharge

Elevated self-discharge typically comes from one or more of these factors:

1.Material contamination or coating defects introduced during electrode manufacturing.

2.Electrolyte impurities or unstable SEI formation, creating unwanted leakage paths.

3.Mechanical stress or compression, damaging the separator and causing micro-shorts.

4.Long-term deep discharge (very low voltage), leading to copper deposition or dendrite formation.

5.Aging and repeated cycles, gradually increasing internal resistance and side reactions.

While some causes originate from usage conditions, the majority can be prevented with proper manufacturing controls.

How Elevated Self-Discharge Affects Performance

·Reduced standby life — batteries stored for short periods may already be low in charge.

·Capacity fade and higher internal resistance — often accompanies increased self-discharge.

·Potential safety risks — abnormal heat generation or internal shorts may begin with elevated leakage current.

·Higher maintenance and replacement costs, especially for OEMs with long supply chains or long inventory cycles.

How Himax Battery Prevents Elevated Self-Discharge

As a professional lithium battery manufacturer, Himax implements a multi-stage quality control process to minimize self-discharge issues:

1. Cell Screening and Self-Discharge Testing

We perform incoming inspection on cells, including self-discharge monitoring and leakage testing. Cells outside our thresholds are rejected.

2. Clean Assembly and Strict Material Control

Our production lines use controlled environments, precision welding, and high-purity electrolyte and separator materials to avoid conductive contaminants.

3. Aging (Stabilization) Tests

After pack assembly, batteries undergo charge/discharge cycles followed by static observation. Packs with abnormal voltage drop or temperature behavior are flagged.

4. BMS Calibration and Low Standby Consumption

We optimize the BMS firmware to ensure low quiescent current and stable protection thresholds.

5. Root-Cause Analysis and Traceability

Any abnormal samples undergo teardown analysis. Findings directly feed back into process improvements and supplier audits.

This ensures every pack leaving Himax meets consistent performance expectations—even after weeks or months of storage.

How Customers Can Prevent Elevated Self-Discharge

OEMs, distributors, and end users can further protect their battery life by following these practices:

1. Check Battery Levels Regularly

Inventory batteries should be inspected periodically and recharged when necessary.

2. Store at Mid-Level SoC

For long-term storage, keep batteries around 30–50% charge, not fully charged or near empty.

3. Avoid Extreme Temperatures

Do not store batteries in hot warehouses, vehicles, or unventilated environments.

4. Do Not Leave Batteries in Deep Discharge

Once a battery hits cutoff voltage, recharge it soon. Long-term zero-voltage storage can cause irreversible damage.

5. Verify Supplier Test Data

When purchasing large quantities, request self-discharge reports, aging test data, and batch traceability.

Himax provides these documents for all OEM clients upon request.

For Product Engineers: System-Level Design Tips

To ensure the best long-term behavior in your device:

·Pick a BMS with low standby current for extended shelf life.

·Implement a gentle wake-up charging routine for deeply discharged packs.

·Provide user prompts for storage and battery maintenance.

·Conduct worst-case temperature × SoC matrix tests during development.

These practices greatly reduce the likelihood of unexpected field failures.

What to Do If You Suspect a Battery Has Abnormal Self-Discharge

1.Stop using the battery and disconnect it from the device.

2.Move it to a cool, ventilated area.

3.Check for symptoms such as swelling, odor, or unusual heat.

4.Provide the batch number, photos, and storage conditions to your supplier for diagnosis.

Himax offers quick technical support and detailed batch analysis for OEM customers.

Conclusion: Himax Battery’s Commitment to Reliability

Elevated self-discharge is both a performance issue and a potential early indicator of internal faults. With proper manufacturing, thoughtful system design, and correct storage practices, it can be prevented or minimized.

Himax Battery is committed to:

·Strict cell selection and pack-level testing

·Comprehensive aging and self-discharge evaluation

·Traceable quality control

·Engineering support for custom pack designs

·Reliable performance for long-storage and high-consistency applications

If you need self-discharge test reports, storage guidelines, or customized pack recommendations for your device, our engineering team is ready to assist.

Find articles related to Battery Discharge