Understanding the Core Differences Between NiMH and Lithium-ion Batteries

Nickel-metal hydride batteries and lithium-ion batteries dominate many commercial applications. Each offers strengths that align with different product needs. Companies must compare both battery types with a clear strategy. One key factor is the stability of a NiMH battery, which many engineers view as dependable for devices that require long-term durability.

Lithium-ion batteries, on the other hand, deliver higher energy density. They power modern mobile electronics, electric vehicles, and smart tools. Their compact size and lightweight build give designers more flexibility. However, their performance depends on extremely stable usage conditions.

When businesses evaluate these two chemistries, they must first understand the operating demands of their product. They should compare energy density, cycle life, charging performance, temperature tolerance, and long-term maintenance. Each factor influences cost, user experience, and safety standards.

Evaluating Energy Density and Power Requirements

A NiMH battery provides moderate energy density, which is appropriate for devices that do not require extreme power output. Products like handheld scanners, medical diagnostic tools, and emergency lights often rely on NiMH because consistency matters more than high peak power.

Lithium-ion batteries outperform NiMH in energy density. Their chemistry allows significantly more watt-hours per kilogram. This gives designers more room to create compact devices. Lithium-ion batteries also support fast charging, which benefits tools, laptops, and mobility equipment.

Companies should examine the long-term power consumption of their applications. If the device runs continuously but does not demand rapid discharge, NiMH may be more cost-effective. If the device needs high voltage stability or quick bursts of power, lithium-ion is often the better option.

Assessing Environmental Tolerance and Safety

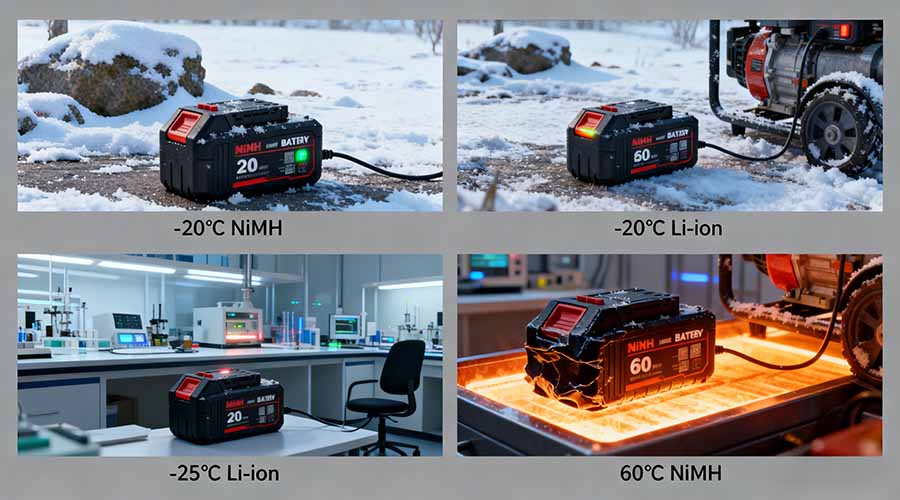

Environmental tolerance plays a major role in battery selection. A NiMH battery performs well in colder climates. This makes it ideal for outdoor equipment, weather monitoring systems, and industrial tools. It also handles overcharging better, which reduces the risk of thermal issues.

Lithium-ion batteries need careful voltage control. They are sensitive to extreme heat, deep discharge, and mechanical impact. For companies producing consumer electronics, advanced battery management systems (BMS) are mandatory to maintain safety. This increases development cost.

Businesses should prioritize safety certification and validate batteries under real-world conditions. If the device will be used by untrained consumers, NiMH might reduce risk. If the device operates in controlled environments, lithium-ion may offer better performance.

Life Cycle Expectations and Maintenance Needs

Companies should project the expected lifetime of the battery in daily use. A NiMH battery typically delivers strong cycle life when maintained properly. It tolerates frequent full discharges and repeated recharging. This characteristic works well for emergency systems and backup power applications.

Lithium-ion batteries offer longer cycle life under partial discharge patterns. They excel in mobile devices because users naturally follow this pattern. But lithium-ion degrades faster in high-temperature environments or under continuous heavy load.

This is why companies must test both chemistries under their unique use scenarios instead of relying on generic cycle life numbers. Planning for maintenance schedules, replacement intervals, and warranty coverage helps avoid long-term costs.

Cost Considerations and Production Planning

A NiMH battery often costs less than lithium-ion. It uses older, more stable manufacturing methods, and the raw materials are widely available. This benefits businesses seeking predictable cost structures. NiMH is also less restricted by international shipping regulations.

Lithium-ion batteries involve higher costs because of their advanced chemistry, protection circuits, and certification requirements. However, economies of scale in consumer electronics have lowered their price significantly in recent years.

When setting budgets, companies should consider not only the battery cost but also the manufacturing environment, required certifications, logistics, and after-sales service. A low-cost battery may still become expensive if it requires frequent replacement.

Matching Battery Type to Industry Applications

The ideal battery depends on the intended industry application. A NiMH battery works well in industries with long replacement cycles, moderate power demands, and outdoor environments. Examples include medical equipment, security systems, communication devices, and industrial tools.

Lithium-ion batteries thrive in applications requiring high efficiency and compact size, such as drones, laptops, electric vehicles, and power tools. Companies focusing on innovation often prefer lithium-ion due to greater design freedom.

Before choosing, teams should map user behavior patterns and device performance expectations. Real-world simulations reveal whether NiMH or lithium-ion is more suitable.

Strategic Recommendations for Corporate Decision-makers

Choosing the right battery model depends on more than technical specifications. A NiMH battery may offer a more predictable performance curve with fewer regulatory hurdles. Lithium-ion batteries may offer superior performance but require greater engineering investment.

To make the best decision, companies should follow these strategic steps:

- Define the device’s power and performance requirements.

- Analyze environmental and safety constraints.

- Estimate total lifecycle cost, not just initial battery cost.

- Conduct prototype testing under real operating conditions.

- Assess compliance and transportation regulations.

- Consider the brand’s long-term sustainability goals.

A careful evaluation ensures the selected battery model aligns with both product performance and business strategy.

HiMAX NiMH Battery Introduction

HiMAX offers high-performance NiMH battery solutions designed for companies that need reliability, safety, and long service life. Our batteries deliver stable output, strong temperature tolerance, and excellent cycle durability, making them ideal for industrial equipment, medical devices, power tools, and consumer electronics. With advanced R&D capabilities and strict quality control, HiMAX ensures every NiMH battery meets global safety standards and supports long-term commercial use. If your business requires dependable, eco-friendly, and cost-efficient NiMH power solutions, HiMAX is ready to be your trusted partner.