As automotive and energy storage designs move toward larger cylindrical cells, housing materials play an increasingly important role. Replacing conventional steel housings with aluminum offers a practical path to better heat transfer, more uniform cell temperatures and improved fast-charge performance — changes that directly affect lifetime, safety margins and pack-level thermal design.

Why housing material matters for large cells

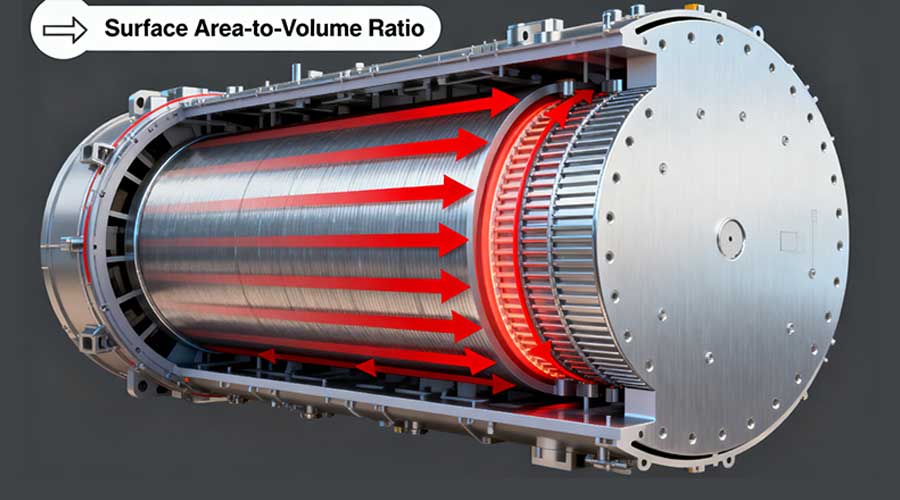

When cell diameter and length increase (for example, modern large-format cylindrical concepts), the ratio of surface area to volume falls. That means heat generated inside the active core has a longer path to reach the outer skin, and conventional low-conductivity housings make it harder to extract that heat efficiently. The housing therefore becomes a critical thermal pathway: a higher-conductivity housing material can move heat more quickly to the pack’s cooling interface, reducing hotspots and enabling higher sustained charge rates.

Safety and mechanical requirements remain essential

Any change in housing material must still meet mechanical and safety constraints. Large cells must withstand internal pressure events and be compatible with standard safety features such as CID opening, venting and cap-expulsion mechanisms that direct gases away from neighboring cells. Engineering the wall thickness and mechanical properties of an aluminum housing requires careful design and validation to maintain burst-pressure integrity and predictable failure modes.

Thermal advantages of aluminum vs steel housings

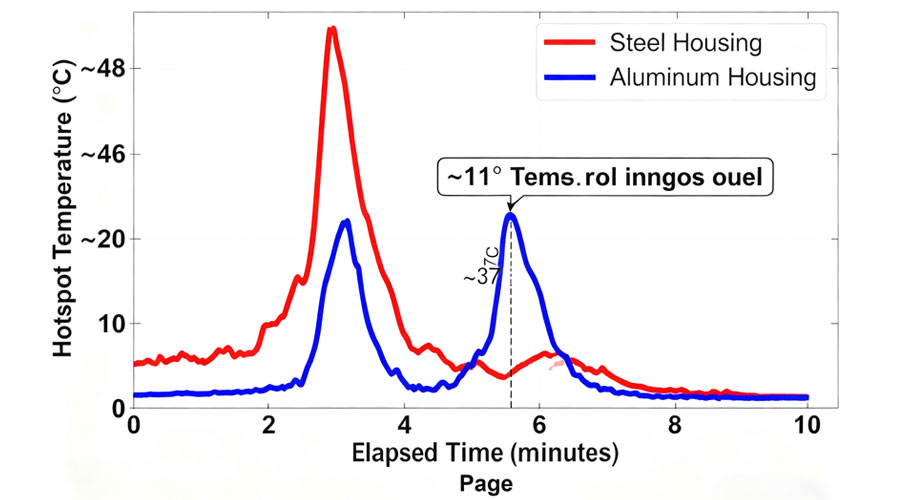

Aluminum alloys have significantly higher thermal conductivity than nickel-plated steel or other common housing materials. Thermal simulations comparing aluminum housings to steel references show meaningful reductions in maximum hotspot temperatures and improved temperature uniformity under high-rate (e.g., 3C) charging. In side-wall cooling configurations, simulation results indicate temperature differences on the order of ~11°C at a 10-minute fast charge window — a difference large enough to materially affect ageing and allowable charge currents.

What this means for fast charging and cycle life

Lower peak temperatures and better thermal homogeneity translate into two practical benefits: faster allowable charge profiles before thermal limits are reached, and slower calendar/cycle ageing driven by hot-spot induced degradation. In other words, an aluminum housing can expand the safe operating envelope for fast charging — provided the rest of the system (cell chemistry, electrode formulation, BMS and cooling contact design) is optimized to match.

Design considerations when using aluminum housings

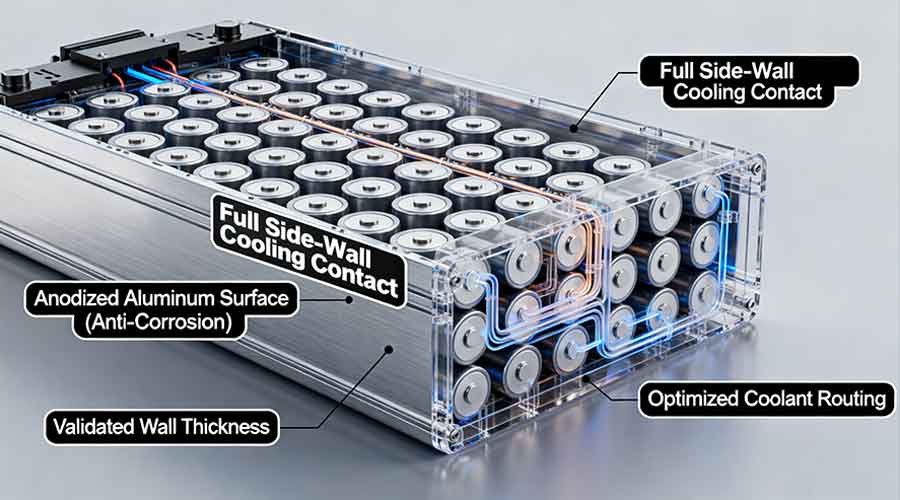

1.Thermal contact design — a high-conductivity housing only helps if heat is efficiently transferred from the housing to the pack cooling system. Ensure consistent contact pressure and a well-designed cooling interface (e.g., full side-wall contact or engineered inserts).

2.Mechanical integrity & thickness optimization — aluminum’s mechanical properties differ from steel; use finite element analysis and validated formulas to size wall thickness to meet burst-pressure requirements while minimizing added mass.

3.Corrosion and surface treatment — consider coatings, anodizing or other surface finishes to prevent galvanic corrosion when aluminum interfaces with other materials and to control electrical isolation.

4.Manufacturing & joining — aluminum welding, brazing or joining techniques differ from steel; plan manufacturing processes, tooling and quality controls accordingly.

5.Pack-level thermal modeling — update system thermal models to reflect the housing’s conductivity and to optimize coolant routing for the best temperature uniformity.

Practical steps for procurement & integration teams

· Request thermal simulations and test data that compare housing materials under your target charge profiles and cooling approach.

· Specify mechanical acceptance criteria (e.g., burst pressure, vent behavior) and require validated FEA or test reports.

· Validate contact resistance and thermal interface design during prototype testing—small gaps or inconsistent contact pressure negate aluminum’s conductivity advantage.

· Confirm manufacturing capability: verify supplier experience with aluminum cell housings at your required production volumes and tolerances.

· Balance mass and performance: aluminum can reduce hotspot temperatures but may alter pack mass and assembly procedures — assess the system-level tradeoffs.

When aluminum housing is most appropriate

· Large cylindrical cells (e.g., 4680-class formats) where surface-to-volume ratios stress thermal design.

· Packs that rely on side-wall cooling or direct cell-to-chassis heat extraction.

· Applications that require improved fast-charge performance without sacrificing cycle life.

Limitations and caveats

Aluminum housing is not a universal fix. Its benefits depend on pack architecture and cooling strategy; poor thermal contact, inferior surface finishes, or inadequate mechanical design can negate any advantage. Additionally, system designers must evaluate manufacturability, corrosion protection and cost impacts relative to the chosen application. Always verify improvements with both simulation and empirical testing before volume production.

Conclusion — a systems approach wins

Switching to an aluminum cell housing can deliver measurable improvements in thermal management, temperature homogeneity and fast-charge capability for large cylindrical cells. However, the housing is only one piece of the puzzle: cell chemistry, electrode engineering, BMS strategy and cooling interface design must be co-optimized to realize the full benefit. For pack designers and bulk buyers, demand comparative thermal data and validated prototypes early in the selection process to turn promising concepts into reliable production outcomes.

About Himax Battery

Himax Battery provides custom pack engineering, cell sourcing and thermal integration services. If you’re evaluating large-format cylindrical cells or considering alternative housing materials for improved fast-charge performance, contact our engineering team for prototype support and comparative thermal testing: services@himaxelectronics.com or https://himaxelectronics.com/contact.

Find articles related to Battery Thermal Management