Meta title: How Temperature Affects Lithium Battery Charging — Best Practices for Safety & Longevity | Himax Battery

Meta description: Learn why temperature is the single biggest factor in charging performance and lifetime of lithium batteries, how to avoid lithium plating and overheating, best charger/BMS features, storage rules and procurement tips for bulk buyers.

Primary keyword: lithium battery charging temperature

Secondary keywords: low-temperature charging, lithium plating, LiFePO4 charging, temperature compensation, BMS temperature protection

TL;DR (for busy procurement / engineering teams)

- Charging outside the recommended temperature window shortens life and can create safety risks — cold charging risks lithium plating, hot charging accelerates degradation.

- For most lithium-ion chemistries, safe charging temperatures are roughly ~]0–45°C (manufacturer-dependent); many recommend 10–40°C as an optimal charging window to avoid plating and excessive aging.

- LiFePO4 chemistry tolerates higher abuse temperatures better than NMC but still suffers capacity loss outside its ideal range; temperature-specific charging strategies and a capable BMS are essential for bulk systems.

1. Why temperature matters more than most engineers expect

Temperature affects reaction rates, internal resistance, SEI (solid electrolyte interphase) growth, and in turn the battery’s ability to accept charge and retain capacity. Heat speeds up chemical side-reactions that permanently reduce cell capacity; cold slows ion transport and increases the chance that incoming lithium will plate on the anode surface instead of intercalating — a root cause of permanent capacity loss and safety risk.

2. Practical temperature thresholds (rules of thumb)

· Cold-charge risk: Charging below ~0°C (32°F) is dangerous — metallic lithium (plating) can form at the anode, causing irreversible capacity loss and increased short-circuit risk. Avoid charging at or below freezing unless the cell or system explicitly supports it.

· Recommended charging window (general): ~10°C–40°C for routine charging; many manufacturers specify safe charging from ~0–45°C but performance and lifetime degrade near extremes. Always confirm with the cell datasheet.

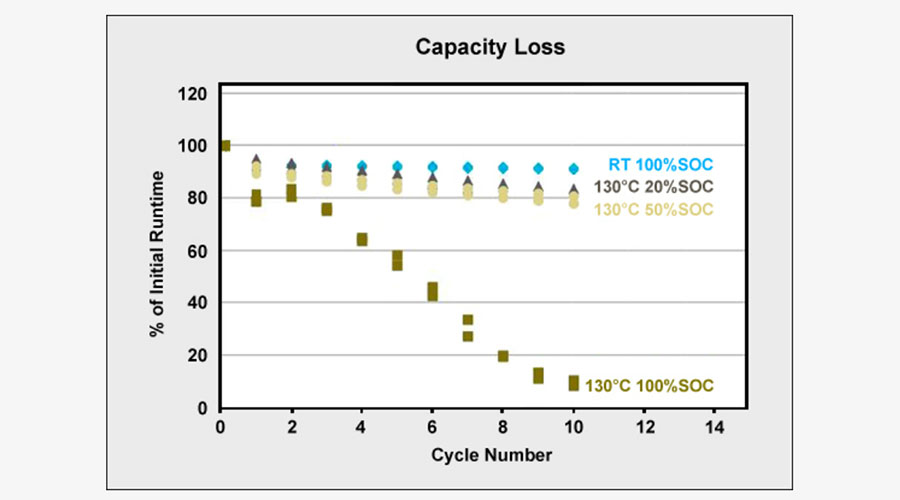

· High-temperature effects: Sustained charging above ~45–50°C accelerates electrolyte decomposition and SEI growth, increasing self-discharge and shortening cycle life. Heat management is essential for fast-charge systems.

Note: exact numbers vary by cell chemistry, formulation and manufacturer — treat the ranges as engineering starting points, not absolute specs.

3. What happens physically at low and high temperatures (expanded)

Low temperatures — lithium plating and increased internal resistance

· Ion mobility drops; at typical charging voltages the anode surface can get metallic lithium deposited instead of allowing ions to intercalate. That plated lithium can become electrically isolated or form dendrites, increasing internal short risk and irreversible capacity loss. This is the main reason many systems prevent charging below a cutoff.

High temperatures — faster aging and safety margins shrink

· Elevated temperatures accelerate side reactions (electrolyte breakdown, SEI thickening). Repeated high-temperature charging cycles multiply capacity fade and can increase self-heating under load. Effective thermal design and conservative float/absorption voltages help mitigate these effects.

4. Chemistry-specific notes (what bulk buyers should know)

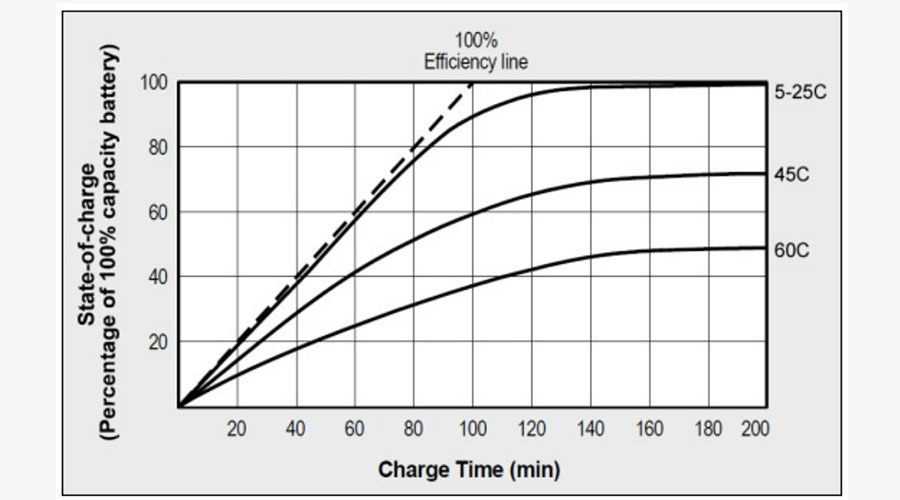

· LiFePO4 (LFP): More thermally stable and safer under abuse; slightly wider thermal window, but still suffers capacity fade and reduced charge acceptance at low T. Testing shows temperature significantly alters LFP charge/discharge behavior and cycle life — adjust charge algorithms accordingly.

· NMC / NCA (typical EV/portable cells): Higher energy density but more temperature-sensitive — more prone to accelerated aging when charged hot and to lithium plating when charged cold.

5. Charger & BMS features you must require (for reliability & safety)

When specifying systems or placing bulk orders, insist on chargers and BMS with:

- Temperature sensing (cell / pack & ambient): multiple sensors, not a single ambient reading.

- Cold-charge inhibit or reduced-current profile: prevent full-current charging below a safe threshold; raise to normal current after cell warms.

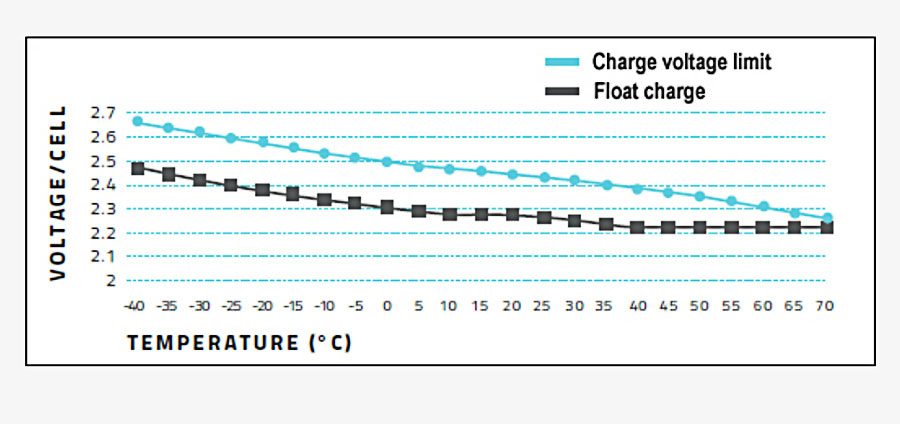

- Temperature-compensated voltage setpoints: adjust float/absorption voltages with temperature (example: lead-acid uses ~3mV/cell/°C — lithium uses different compensation logic or current-limited strategies).

- Adaptive charge rates: reduce C-rate as cell temp rises above safe thresholds; allow temporary higher C only if short-duration and well-cooled.

- Thermal runaway monitors and fail-safe disconnects for large packs.

Including these items in RFPs reduces warranty exposure and improves lifetime for customers.

5. Charger & BMS features you must require (for reliability & safety)

When specifying systems or placing bulk orders, insist on chargers and BMS with:

- Temperature sensing (cell / pack & ambient): multiple sensors, not a single ambient reading.

- Cold-charge inhibit or reduced-current profile: prevent full-current charging below a safe threshold; raise to normal current after cell warms.

- Temperature-compensated voltage setpoints: adjust float/absorption voltages with temperature (example: lead-acid uses ~3mV/cell/°C — lithium uses different compensation logic or current-limited strategies).

- Adaptive charge rates: reduce C-rate as cell temp rises above safe thresholds; allow temporary higher C only if short-duration and well-cooled.

- Thermal runaway monitors and fail-safe disconnects for large packs.

Including these items in RFPs reduces warranty exposure and improves lifetime for customers.

7. Storage & transport temperature guidance

· Short term storage (days-weeks): Store at moderate SOC (~30–50%) and room temp.

· Long term storage (months): Store at lower SOC (20–40%) and cool, dry conditions; avoid storing fully charged at high temp. Heat while at high SOC produces worst aging.

8. Testing checklist for bulk procurement (what to demand from suppliers)

When you buy in volume, include these tests in contracts or incoming QA:

· Charge acceptance vs temperature curve: show capacity retention and coulombic efficiency tested at multiple temps (e.g., -10°C, 0°C, 10°C, 25°C, 45°C).

· Cold-charge plating test: explicit test demonstrating resistance to lithium plating or defined recovery procedure.

· Cycle life at elevated temperatures: accelerated aging test at 45°C or 60°C for X cycles with reported capacity retention.

· Thermal imaging during fast charge: verify hotspots are within spec.

· BMS thermal management validation: log showing how BMS reduces current or isolates pack when temps exceed thresholds.

Including these items in purchase orders reduces surprises and supports warranty claims.

9. Design recommendations for system integrators

· Place temperature sensors close to the cells, not just on the case. Pack thermal gradients are common.

· Allow controlled pre-warming in cold climates: small, low-current “pre-heat” can bring cells into safe charging window without damage.

· Combine passive and active cooling for fast-charge systems — fans, heat plates, or phase-change materials as needed.

· Document temperature-dependent derating in datasheets given to customers.

10. Short FAQ

Q: Can I charge lithium batteries in winter?

A: Yes — but avoid charging below the cell’s specified low-temperature limit (commonly ~0°C). If charging in cold weather is unavoidable, use pre-warm routines or reduced charge currents to avoid lithium plating.

Q: Will charging at high temperatures speed charging?

A: Higher temperatures may increase charge acceptance short-term, but they dramatically accelerate aging. Design charge systems to avoid prolonged high-temperature charging.

Q: Are LiFePO4 batteries immune to temperature issues?

A: LFP is more stable and safer than some chemistries, but it still needs temperature-aware charging to maximize cycle life.