Over the years, the term “polymer battery” has become a popular label for many lithium-based batteries — but not all of them actually use polymer materials. These batteries are often built in pouch or prismatic cell formats, giving them a lightweight and flexible design that appeals to modern electronics manufacturers.

While the word “polymer” may remind people of plastics, polymers are actually a broad class of materials — ranging from synthetic plastics to natural biopolymers and proteins that are essential to biological structures.

Understanding the Lithium-Polymer Difference

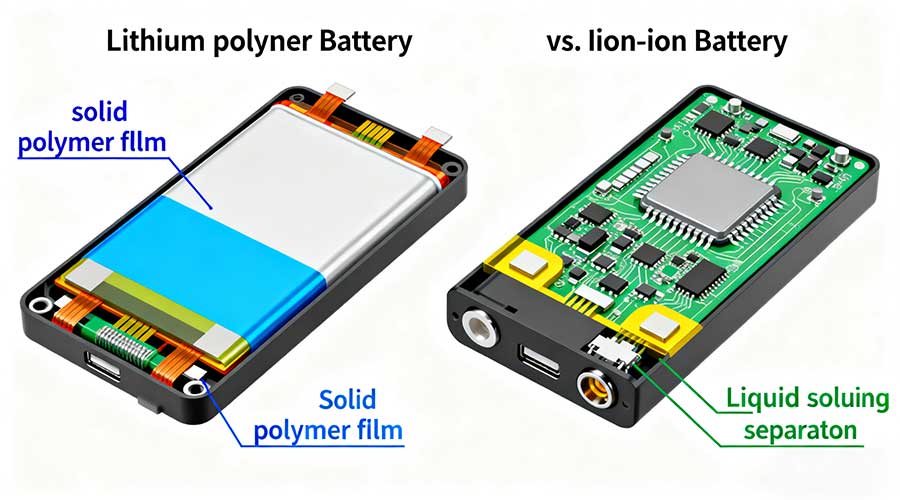

The key distinction between lithium-polymer (Li-poly) and other lithium-based batteries lies in the electrolyte composition.

Early research in the 1970s explored a solid polymer electrolyte — a dry, plastic-like film that could transport lithium ions without the need for a liquid solvent. This film replaced the porous separator soaked with electrolyte used in conventional Li-ion batteries.

However, the solid polymer design suffered from poor conductivity at room temperature, requiring the cells to be heated to around 60°C (140°F) or higher for acceptable performance. Though some large-format polymer batteries were built for stationary applications, they gradually disappeared due to inefficiency and cost.

By the early 2000s, expectations for a “true plastic battery” faded, as no manufacturer succeeded in achieving high conductivity at ambient temperatures.

Modern Li-Polymer: The Gel Revolution

To overcome these challenges, today’s Li-polymer batteries use a gelled electrolyte that improves ion flow at room temperature. Most modern Li-poly cells combine this gel with a microporous separator, allowing for better performance and flexibility.

Importantly, Li-polymer is not a distinct chemistry — it can be built using Li-cobalt oxide (LiCoO₂), NMC, Li-phosphate, or Li-manganese systems. The main structural difference lies in how the electrolyte and separator are engineered.

From a user’s perspective, Li-polymer and Li-ion batteries perform almost identically. Both share similar cathode and anode materials and operate with comparable voltage and charging profiles.

Design and Advantages of Pouch Cells

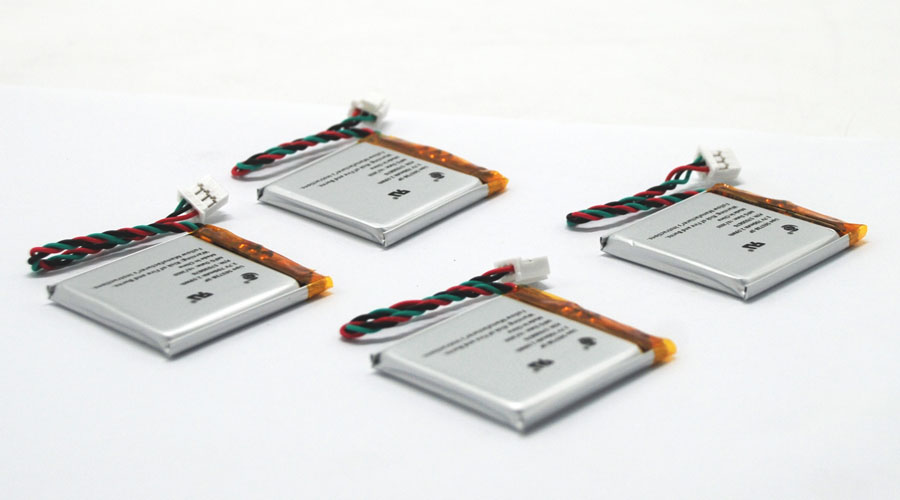

A major benefit of lithium-polymer technology is its lightweight and flexible packaging.

Instead of a rigid metal casing, Li-polymer cells use laminated aluminum foil pouches, which reduce battery weight by over 20% compared to traditional cylindrical cells. This flexible structure enables manufacturers to design ultra-thin batteries that fit into modern smartphones, tablets, and wearable devices.

At Himax Battery, our engineers leverage advanced pouch-cell manufacturing to deliver batteries that combine high energy density, slim design, and reliability — making them ideal for applications where form factor and performance both matter.

Performance and Safety Considerations

Charging and discharging behaviors of Li-polymer batteries are almost identical to conventional Li-ion systems. They can be charged with the same type of chargers and offer similar energy profiles.

However, like all lithium-based technologies, proper protection circuitry is essential. During charging, some pouch or prismatic cells can expand slightly due to gas formation. Himax designs its battery enclosures with safety margins to accommodate this expansion, ensuring consistent long-term reliability.

One trade-off of the foil packaging is durability — while lighter, it may not offer the same mechanical strength as the cylindrical cell’s hard casing. Nonetheless, for most consumer electronics, drones, and RC devices, the weight savings and flexibility far outweigh this limitation.

Lithium Polymer Is Substance with Style

While the early promise of an all-plastic “super battery” never became reality, modern lithium-polymer technology has evolved into a practical and powerful solution for next-generation devices.

At Himax Battery, we continue to push the boundaries of Li-polymer design, delivering batteries that balance high specific energy, slim structure, and dependable safety — proving that lithium polymer is not hype, but a real innovation shaping the future of portable power.