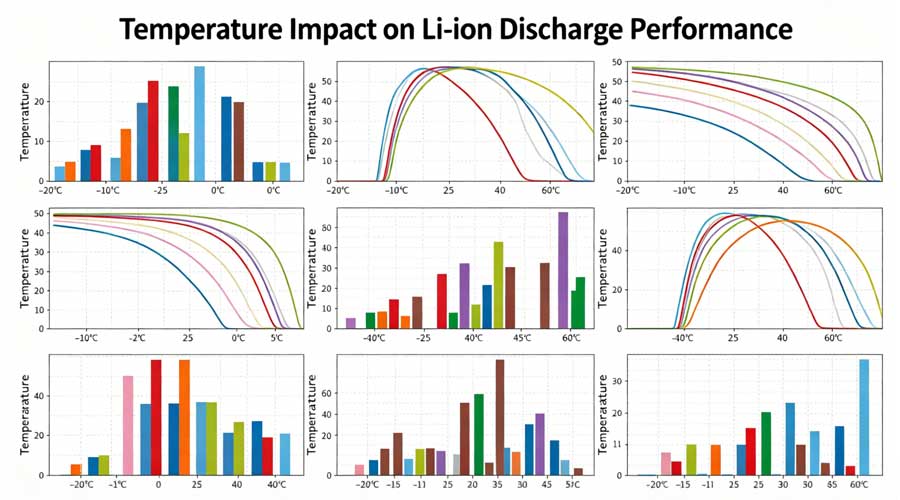

Lithium-ion batteries perform best around room temperature. As with most electrochemical systems, deviations toward high or low temperatures degrade performance, reduce usable capacity, and shorten overall lifespan.

In this article, we explain why temperature extremes impact discharge behavior, provide quantitative guidance with tables, and share practical recommendations from a manufacturing perspective to help your devices, packs, or systems operate safely and reliably under challenging conditions.

1. How Temperature Affects Discharge Performance

1.1 Internal Resistance and Reaction Kinetics

· At low temperatures, electrolyte ion mobility decreases and electrode reactions slow down. This raises internal resistance (IR) and reduces current output for a given voltage.

· At high temperatures, reactions accelerate, giving a short-term boost in discharge performance. However, prolonged exposure to heat accelerates degradation, such as side reactions and growth of internal resistance.

· Example: a cell rated at 100% capacity at 27 °C might deliver only ~50% at –18 °C.

1.2 Lifespan Penalty from Elevated Temperatures

Prolonged exposure to high temperature can permanently reduce cycle life:

· At 30 °C: cycle life reduced by ~20%

· At 40 °C: cycle life reduced by ~40%

· At 45 °C+: lifespan can be cut nearly in half

1.3 Recovery After Temperature Normalization

Capacity loss at low temperature is largely reversible once the battery returns to normal conditions. By contrast, heat-induced damage is typically permanent.

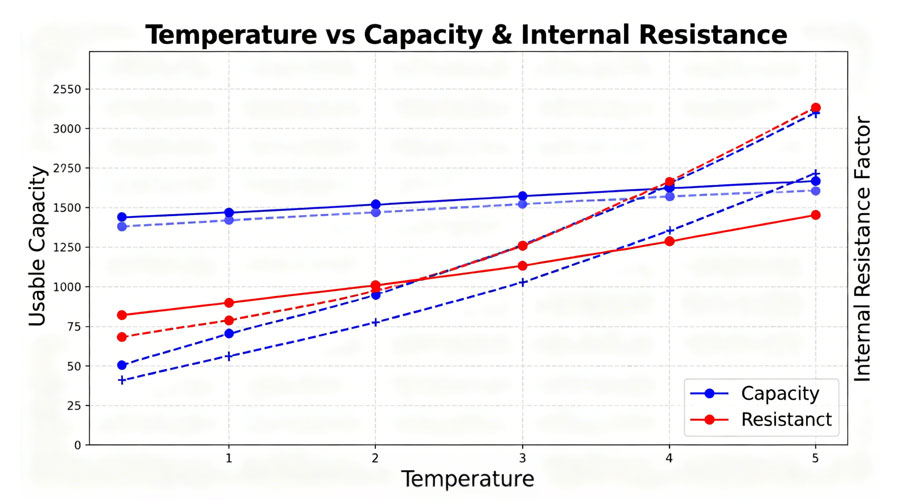

2. Quantitative Data & Comparison

| Temperature | Usable Capacity (% of nominal) | Internal Resistance Factor | Notes |

| 25 °C (baseline) | 100% | 1× | Optimal |

| 30 °C | ~100–105% | ~0.9–1.1× | Slight performance benefit but faster aging |

| 40 °C | ~100% | ~1.2× | Higher stress, no real gain |

| 45 °C | ~95–100% | ~1.3× | Accelerated degradation |

| 60 °C+ | — | — | Risk of severe damage |

| 0 °C | ~60–70% | ~2–3× | Voltage drop under load |

| –10 °C | ~50–60% | ~3–4× | Significantly limited output |

| –20 °C | ~40–50% | ~4–5× | Very limited capacity |

| Temperature | Voltage Sag at 1C Load |

| 25 °C | Baseline (e.g., 3.7V) |

| 0 °C | ~10–20% drop |

| –20 °C | ~20–30% drop |

3. Best Practices for Managing Temperature Effects

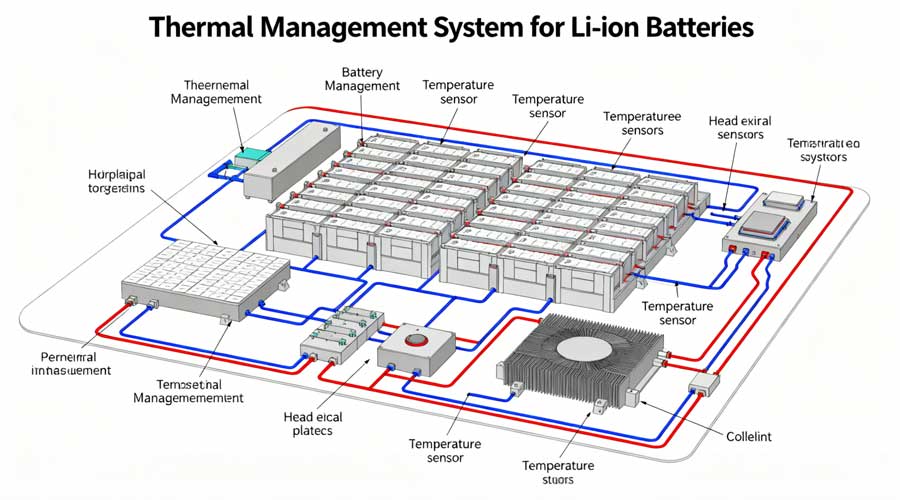

3.1 Design-Level Mitigations

· Thermal management: integrate cooling, ventilation, or liquid thermal systems in packs.

· Insulation and preheating: essential for devices used in cold climates.

· Cell matching: prevents weak cells from reversing during cold or high-load conditions.

3.2 Operating Strategies & BMS Control

| Scenario | Strategy |

| Cold start (below 0 °C) | Limit discharge rate (<0.5C) until warmed; preheat if possible |

| High ambient temperature (>45 °C) | Reduce load, apply thermal cutoffs |

| Variable loads | Avoid heavy discharge under extreme conditions |

| Safety monitoring | Track IR and cell voltages; stop before deep reversal |

3.3 Application-Specific Recommendations

· Electric Vehicles (EVs): Use preconditioning in cold climates; thermal management is critical in hot regions.

· Energy Storage Systems (ESS): Maintain controlled ambient environment (15–30 °C); shallow cycling improves lifespan.

· Consumer Electronics & Tools: Software derating helps protect cells in outdoor cold-weather use.

4. Frequently Asked Questions (FAQ)

Q1: Is cold discharge damage permanent?

No, reduced performance in cold conditions is mostly reversible when the cell warms.

Q2: Can oversizing the battery help in cold weather?

Yes, but it adds cost and weight. Thermal management is a better long-term solution.

Q3: Is it safe to discharge at –40 °C?

Only with special cells designed for such extremes, and at very low currents (≤0.2C).

Q4: How do manufacturers test temperature performance?

Using environmental chambers, measuring discharge capacity, voltage drop, and resistance at multiple temperatures.

5. Conclusion

· Cold temperatures reduce immediate capacity due to high resistance, but effects are reversible.

· High temperatures provide short-term discharge efficiency but cause irreversible degradation.

· Smart thermal management + BMS control is essential to balance safety, lifespan, and performance.

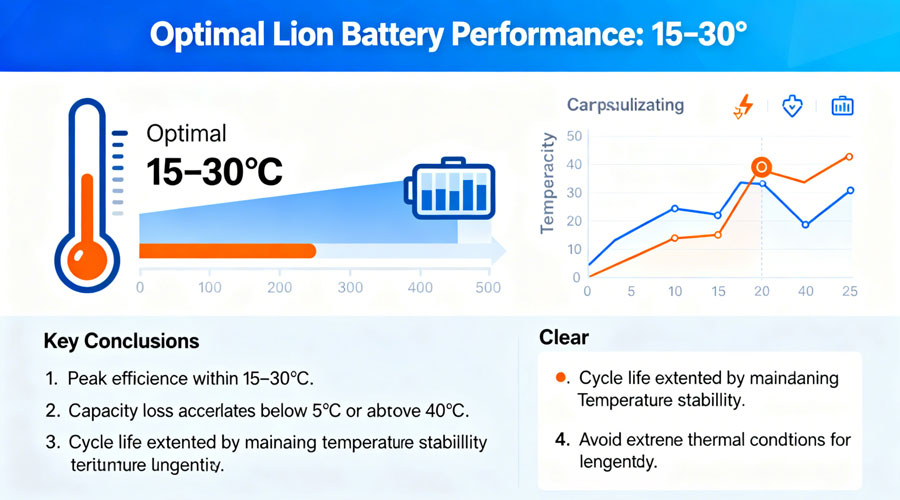

From our factory experience, the optimal performance window is 15–30 °C. By integrating proper design, monitoring, and usage practices, you can extend both the usability and lifespan of lithium-ion batteries in real-world applications.