Lithium Iron Phosphate (LFP) batteries have become increasingly popular in electric vehicles (EVs), energy storage systems (ESS), and consumer electronics due to their high safety, long cycle life, and cost-effectiveness.

However, even the best battery chemistry will degrade quickly if charged improperly. The charging method directly affects safety, performance, and lifespan.

This article provides a comprehensive guide to charging LFP batteries, including recommended voltage ranges, charging strategies, application-specific practices, and answers to frequently asked questions.

1. Charging Characteristics of LFP Batteries

1.1 Key Chemistry Features

· Nominal voltage: 3.2–3.3V per cell

· Energy density: Lower than NMC/NCA, but with superior safety

· Thermal stability: Excellent resistance to overheating and thermal runaway

1.2 Charging Curve

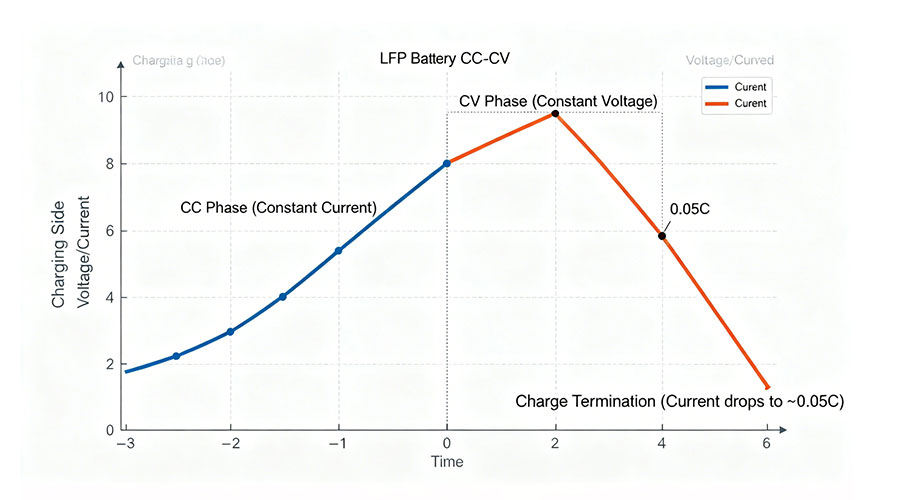

LFP batteries follow a CC-CV (Constant Current – Constant Voltage) charging profile:

- CC Phase – Current remains constant, voltage gradually increases.

- CV Phase – Voltage stays constant, current gradually decreases.

- Charge termination – Charging stops when current drops to ~0.05C.

Compared with NMC batteries, LFP’s voltage curve is flatter, meaning accurate BMS (Battery Management System) control is critical for precise SOC (State of Charge) estimation.

2. Recommended Charging Voltage and Strategy

2.1 Charging Voltage Settings

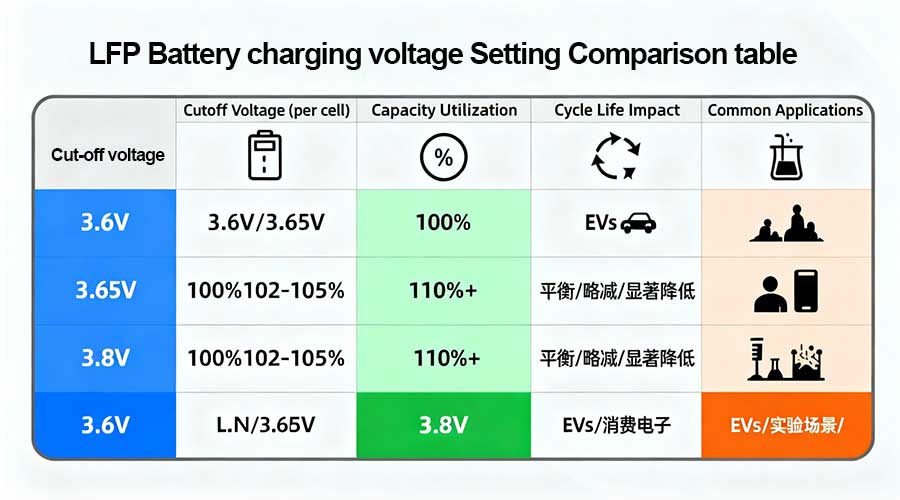

| Cutoff Voltage (per cell) | Capacity Utilization | Cycle Life Impact | Common Applications |

| 3.6V | ~100% | Balanced lifespan | EVs, general use |

| 3.65V | ~102–105% | Slightly reduced | Consumer electronics |

| 3.8V | ~110%+ | Significantly reduced | Rare use, experimental |

�� Best practice: Use 3.6–3.65V per cell in most cases.

2.2 Charging Current

| Current (C-rate) | Charge Time | Cycle Life Impact | Suitability |

| 0.3–0.5C | 2–4 hours | Maximized lifespan | Energy storage, long-life devices |

| 0.5–1C | 1–2 hours | Balanced | EVs, daily charging |

| >1C | <1 hour | Reduced lifespan, higher heat | Fast charging scenarios |

2.3 Risks of Overcharge and Undercharge

| Condition | Impact on Battery | Recommendation |

| Overcharge | Electrolyte decomposition, impedance rise, safety risks | Avoid >3.65V |

| Undercharge | Lower usable capacity, extended cycle life | Useful in ESS |

3. Charging Strategies by Application

| Application | Voltage Setting | Current Recommendation | Special Considerations |

| Electric Vehicles (EVs) | 3.6–3.65V | 0.5–1C (with fast charge support) | BMS control is critical; daily charging often limited to 80–90% SOC |

| Energy Storage Systems (ESS) | 3.45–3.5V | 0.3–0.5C | Conservative charging extends lifespan; shallow cycling preferred |

| Consumer Electronics | Up to 3.65V | 0.5–1C | Higher voltage for maximum runtime; limited space for cooling |

4. Frequently Asked Questions (FAQ)

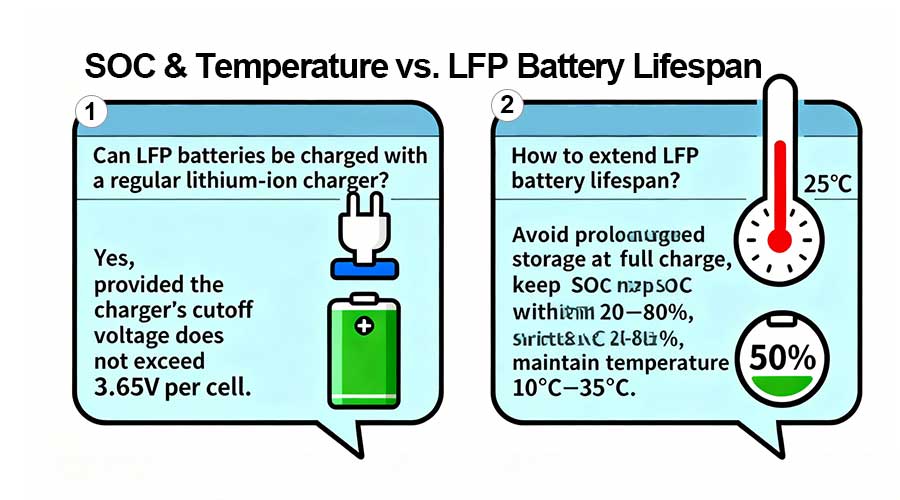

Q1: Can LFP batteries be charged with a regular lithium-ion charger?

Yes, provided the charger’s cutoff voltage does not exceed 3.65V per cell.

Q2: Why is the voltage lower than NMC batteries?

LFP chemistry has a lower electrochemical potential, resulting in a nominal voltage of ~3.2V compared to ~3.6–3.7V for NMC.

Q3: Are LFP batteries suitable for fast charging?

Yes, at moderate rates (~1C). However, higher currents reduce cycle life and require effective thermal management.

Q4: How can I extend LFP battery lifespan?

· Avoid prolonged storage at full charge

· Keep SOC within 20–80% when possible

· Maintain operating temperature between 10°C–35°C

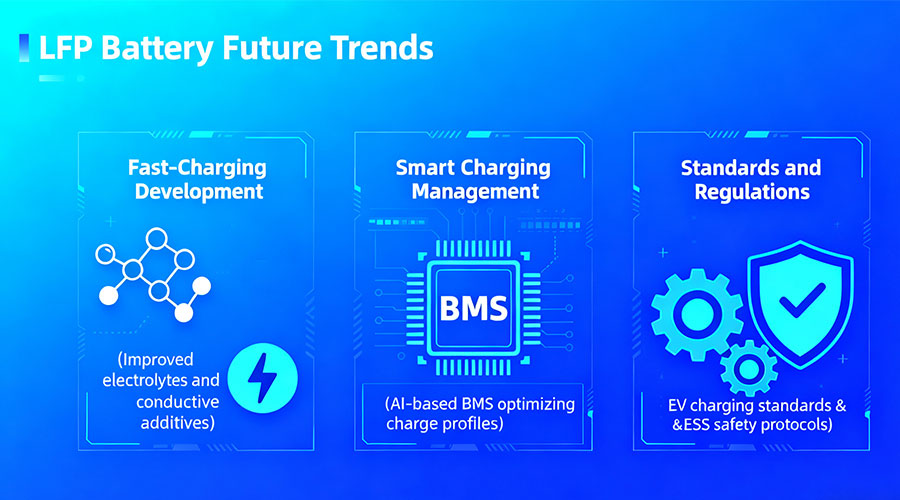

5. Future Trends and Industry Outlook

1. Fast-Charging Development

o Improved electrolytes and conductive additives

o Safer high-rate charging technologies

- Smart Charging Management

o AI-based BMS optimizing charge profiles in real time

o Data-driven lifetime prediction and adaptive charging

- Standards and Regulations

o EV charging standards are becoming stricter

o ESS systems adopting unified safety protocols

LFP batteries are among the safest and longest-lasting lithium-ion chemistries, but achieving optimal performance requires proper charging strategies.

· Voltage range: 3.6–3.65V

· Recommended current: 0.5–1C

· Application-specific optimization is key: EVs prioritize performance, ESS values longevity, and electronics balance runtime with size constraints.

From our factory-level experience, the best results come from combining moderate cutoff voltage with controlled current rates—ensuring both performance and long-term reliability.