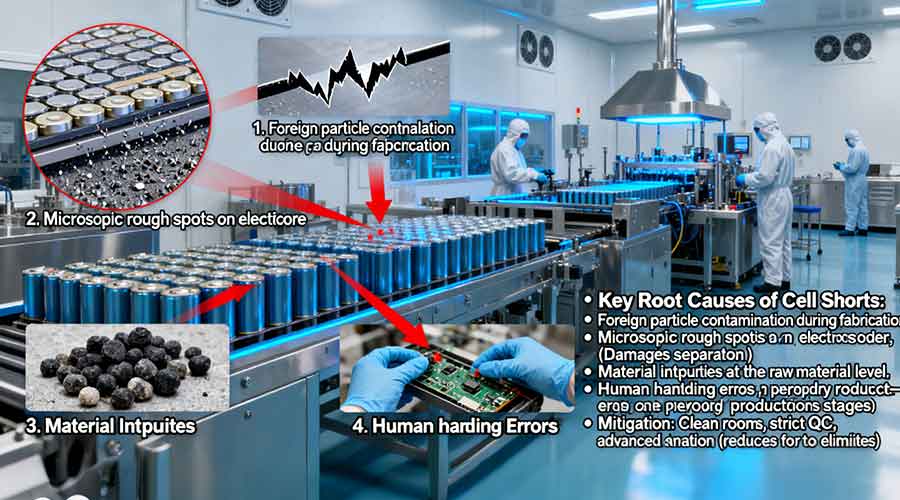

Understanding Cell Shorts in Battery Manufacturing

Even with modern production methods, battery cell shorts remain a persistent challenge for manufacturers. A short circuit or excessive electrical leakage can appear in new cells before they ever leave the factory. These failures reduce reliability and may create serious safety risks.

The root causes often include:

· Foreign particle contamination during fabrication

· Microscopic rough spots on electrodes that damage separators

· Material impurities at the raw material level

· Human handling errors during early production stages

To minimize risks, manufacturers rely on clean rooms, strict quality control, and advanced automation. These measures have significantly lowered defect rates, but eliminating shorts entirely remains difficult.

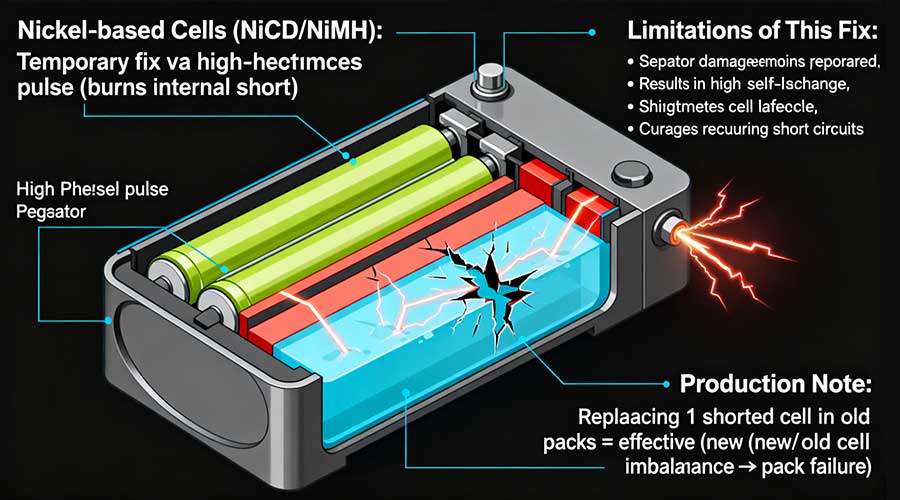

Why Cell Shorts Are Difficult to Repair

In nickel-based chemistries (NiCd and NiMH), some manufacturers have experimented with applying high-current pulses to “burn off” an internal short. While this may temporarily restore performance, the separator damage remains. Such cells often show:

· High self-discharge

· Shortened lifespan

· Recurring short circuits

From a production standpoint, replacing a single shorted cell in an aging pack is rarely effective. Stronger new cells quickly fall out of balance with older ones, leading to pack failures within months.

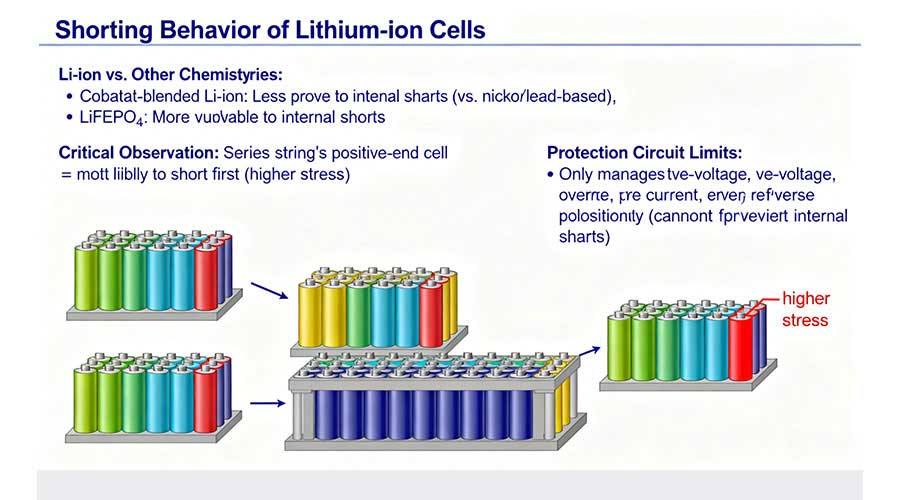

Lithium-ion Cells and Shorting Behavior

Compared to nickel- and lead-based batteries, cobalt-blended lithium-ion cells are less prone to internal shorts. However, some chemistries, such as lithium iron phosphate (LiFePO₄), may be more vulnerable.

Industry data suggests that the cell at the positive end of a series string is most likely to short first, possibly because it experiences higher stress. Even with mandatory protection circuits, internal shorts cannot be prevented. Protection circuits are only designed to manage:

· Over-voltage

· Over-current

· Reverse polarity

An internal short caused by structural cell damage lies beyond these safeguards.

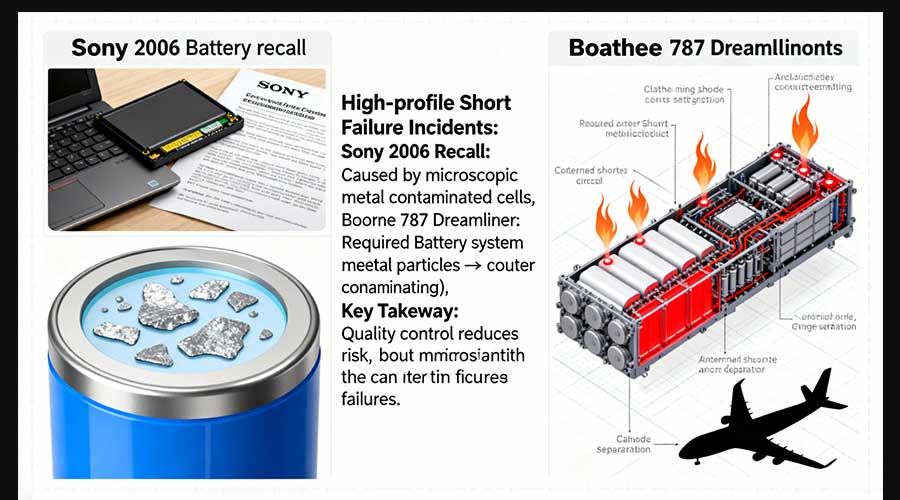

Real-world Cases of Cell Short Failures

Even certified, high-quality lithium-ion batteries have experienced shorts during service:

· Sony 2006 Recall – Caused by microscopic metal particles contaminating cells.

· Boeing 787 Dreamliner – Required battery system redesign after internal shorts led to overheating.

These incidents highlight that while quality control reduces risks, microscopic defects can still trigger failures.

Environmental and Mechanical Causes of Shorts

Many shorts develop due to external stress rather than factory defects. Common causes include:

· Shock and vibration during transport or use

· Overcharging beyond safe voltage thresholds

· Overheating under heavy load or poor cooling

· Charging at freezing temperatures, which can damage separators without visible warning

For safety, manufacturers must design packs with reinforced separators, thermal sensors, and advanced battery management systems (BMS) to reduce risks.

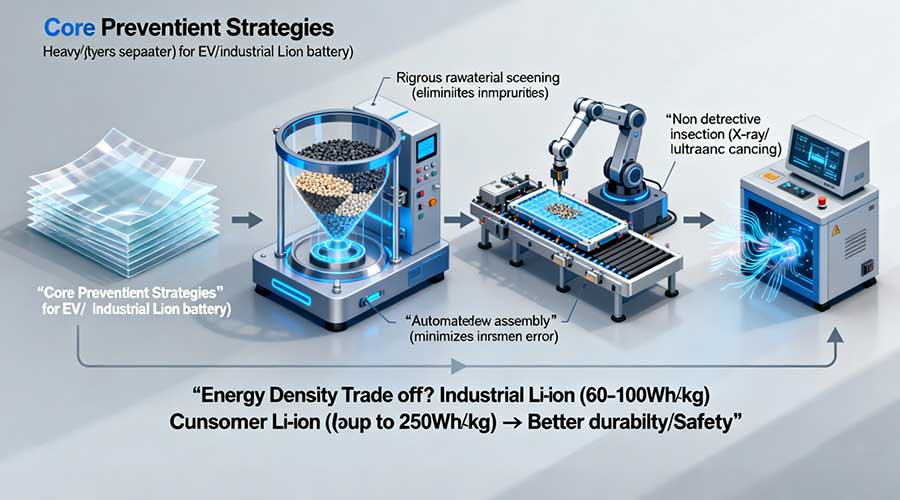

Manufacturing Strategies to Prevent Shorts

Battery manufacturers employ several strategies to reduce the chance of shorts:

· Heavy-duty separators for EV and industrial-grade Li-ion batteries

· Rigorous raw material screening to eliminate impurities

· Automated assembly to minimize human error

· Non-destructive inspection methods such as X-ray or ultrasonic scanning

It’s important to note that long-lasting industrial Li-ion cells often trade energy density for durability and safety. While consumer Li-ion cells may reach up to 250Wh/kg, industrial-grade Li-ion may range between 60–100Wh/kg — comparable to NiCd but with far greater stability.

Important Safety Note

⚠️ High-current bursts should never be applied to lithium-ion cells. While this method has occasionally been used on nickel-based batteries, attempting it on Li-ion cells may cause catastrophic failure, fire, or explosion.

✅ In summary:

Cell shorts remain a critical challenge in battery manufacturing. They can arise from contamination, electrode flaws, or stress during use. While nickel-based cells sometimes allow temporary fixes, lithium-ion cell shorts are permanent and cannot be repaired. Manufacturers can only minimize risks through clean manufacturing, advanced quality control, and stronger cell designs to ensure long-term safety and reliability.