Lithium ion battery safety is not optional. It is essential. A lithium ion battery can power your products, your trucks, and your plant. But without clear rules and good design, the same battery can become a hazard. This guide explains simple, practical steps you can take right now to secure operations and reduce the chance of a fire.

Why Safety Matters — Plain and Simple

A battery stores energy like a coiled spring. When it is released in the wrong way, the result is sudden and dangerous. The most common causes of failures are poor handling, bad design, and overlooked maintenance. Thermal events, overcharging, and physical damage can escalate fast. Do you want your equipment to be reliable or to be a risk? The answer should guide every purchase and every procedure.

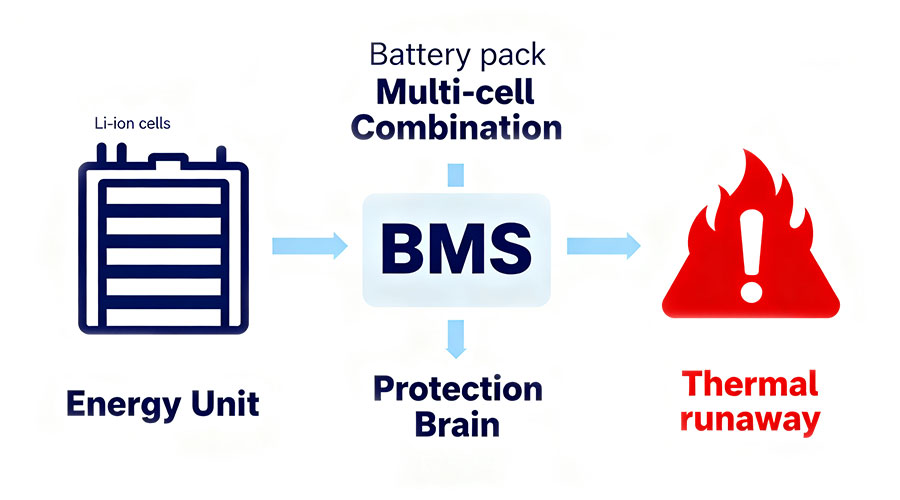

Know Your Components (and Name Them)

Learn the parts of the system. Words matter. When you talk to suppliers, use the right terms so everyone understands the risk and the fix.

· Li-ion cells: the little energy units inside a pack. Treat them with care.

· Battery pack: a group of cells assembled to deliver voltage and capacity.

· Battery management system (BMS): the brain that protects cells from overcharge, overdischarge, and imbalance.

· Cell balancing: the process that keeps cell voltages equal so one cell does not fail early.

· Charge controller and overcharge protection: devices and features that prevent unsafe charging.

· Thermal runaway: the rapid, uncontrolled rise in temperature that can lead to fire.

· Fire suppression: equipment and plans to stop a small fire from becoming a catastrophe.

Simple Design Choices That Save Lives

Good design is the first line of defense. It is cheap compared with a fire or a large recall.

· Use a reputable battery pack supplier that specifies cycle life, C-rate, and energy density clearly.

· Require a robust battery management system (BMS) with overcurrent, overtemperature, and cell-voltage monitoring.

· Prefer cells with proven chemistry for your use case, such as LiFePO4 where thermal stability matters.

· Ensure proper cell balancing in multi-cell packs. Imbalanced cells age faster and can fail.

· Add mechanical protection so cells are not crushed, punctured, or jarred. Simple engineering can prevent complex failures.

Storage, Charging, and Handling — Do These Every Day

Operations fail when routine tasks are sloppy. Clean routines protect you.

· Store batteries in cool, dry areas away from combustible materials. Keep separate the charged packs from the uncharged ones.

· Use chargers that match the pack’s specification. A mismatch can overcharge cells.

· Train staff to handle packs gently. No sharp impacts. No short circuits. No improvisation.

· Keep records: when a pack arrived, when it was tested, and when it was serviced. History helps you spot a problem early.

Monitoring and Maintenance — Don’t Trust Luck

Monitoring is not just about glancing at a battery indicator. It is about collecting real data and acting on it. A lithium ion battery works within precise parameters. If you know those numbers, you can predict problems before they become accidents.

Key Parameters to Monitor

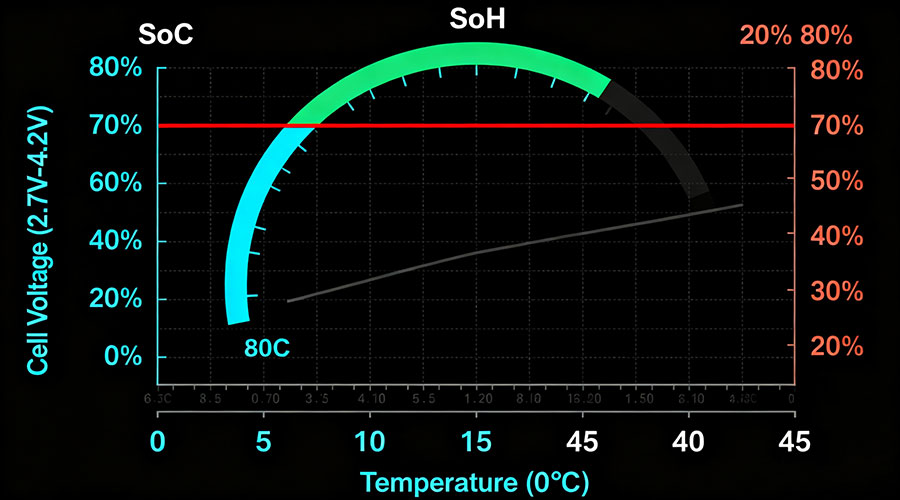

· State of Charge (SoC): Keep most packs between 20% and 80% SoC for long life. Dropping below 10% or charging to 100% regularly can cut cycle life by more than 30%.

· State of Health (SoH): Replace packs when SoH drops below 80% of original capacity. For example, a 100Ah pack that only delivers 78Ah is reaching the end of its safe service.

· Voltage per cell: Most li-ion chemistries should stay between 2.7V and 4.2V per cell. A cell dropping below 2.5V risks copper dissolution, while going above 4.25V risks thermal runaway.

· Temperature: Safe charging range is typically 0°C to 45°C, and safe discharge is -20°C to 60°C. If cells exceed 60°C, internal chemical reactions accelerate dangerously.

· Cycle count: A good pack lasts 500–2000 cycles depending on chemistry. Track cycles to plan replacement before failures.

Maintenance Practices to Adopt

· Routine inspections: Visually check for swelling, leaks, or discoloration of cells and packs every quarter.

· BMS testing: Confirm that overcharge, overdischarge, and short-circuit protections work. For example, verify that discharge is cut off if pack voltage drops below 2.8V per cell.

· Firmware updates: Ensure the BMS firmware is current. Outdated code may miscalculate SoC or SoH.

· Capacity testing: Every 6–12 months, perform a controlled full discharge test. If capacity has dropped more than 20%, schedule replacement.

· Thermal scanning: Use an infrared camera to detect hotspots during charging/discharging. A cell running 5–10°C hotter than others may signal early failure.

· Data logging: Keep digital records of voltage, current, and temperature trends. Patterns often reveal issues that a one-time test cannot.

Why Proactive Monitoring Pays Off

Imagine running a fleet of delivery trucks powered by lithium ion batteries. One overheated cell can stop a truck and cost thousands in lost revenue. But with proper logging and regular checks, that weak cell would be flagged weeks earlier. Monitoring turns surprises into scheduled maintenance, reducing downtime and protecting people.

Fire Prevention and Emergency Planning

Prevention is parallel to preparation. Both matter.

· Design facilities with separation, ventilation, and fire suppression systems suited for battery fires.

· Install thermal detectors where battery banks are stored. Smoke detectors often activate too late.

· Train staff with clear steps and drills. Know who calls whom and what equipment to use.

· Have a response plan for recall and disposal. A used battery is not trash. It is hazardous waste that needs proper handling.

Purchasing: Pick Partners Who Share Responsibility

Buying decisions affect safety. Ask hard questions.

· Does the manufacturer provide test reports and certifications? Demand them.

· Does the supplier offer technical support for integration and OEM orders? Good partners help you avoid mistakes.

· Can they supply wholesale quantities safely and consistently? Volume should not mean cutting corners.

· Are samples available for validation in your system? Test packs under real conditions.

Common Myths — Busted

Myth: “All lithium batteries are the same.” False. Chemistry, cell format, assembly, and electronics all vary.

Myth: “A fire cannot happen to us.” Do you store, charge, transport, or install batteries? Then your risk exists.

Myth: “Quick fixes are fine.” Temporary workarounds become permanent hazards.

Practical Checklist Before Deployment (Short and Actionable)

· Confirm chemistry and specs.

· Verify BMS functions and firmware.

· Inspect for mechanical damage.

· Validate chargers and cable gauges.

· Schedule routine SoC/SoH checks.

· Train staff and run a fire drill.

The Payoff: Reliability, Savings, and Trust

Take safety seriously and you get more than reduced risk. You get uptime, lower insurance costs, fewer recalls, and stronger customer trust. Safety is not a cost center. It is an investment with compound returns.

Final Thoughts — A Quick Metaphor to Remember

Think of batteries as a fleet of small engines. Maintain them, monitor them, and they will serve you faithfully. Ignore them, and they will fail in ways that are loud, expensive, and avoidable.

About HiMAX Battery

For Document 102 (Li-Ion Battery Safety Theme)

When it comes to safe Li-ion battery operations, HiMAX Battery is a trusted global provider of efficient, custom new-energy solutions. As a direct factory supplier, we eliminate extra costs and ensure clear communication, with a range of chemistries (including heat-stable LiFePO4) to fit safety-focused needs. We customize voltage, capacity, and physical specs, turn around designs in 3 days and samples in 7 days, and offer free first-order samples—all backed by safety-first engineering support to keep your Li-ion battery operations secure.