If you handle wholesale lipo batteries, inspect incoming stock, store packs correctly, and use certified chargers and BMS. Do this and you’ll cut failures and returns. Quick tip: add a printable QC checklist to every shipment.

Why LiPo cells swell (short science)

LiPo cells swell because internal gases form when the electrolyte or electrode degrades. Overcharge, overheating, and ageing speed this up. Therefore, design and QC matter. This is well documented in battery safety literature. what to do with a swollen battery.

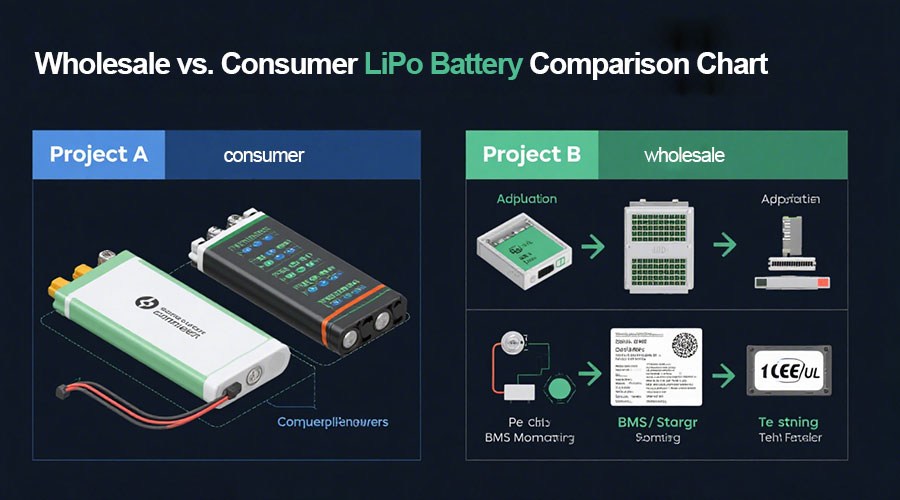

Quick buyer comparison (Project A vs Project B)

| Aspect | Project A — Consumer LiPo | Project B — Wholesale / Industrial LiPo Batteries |

| Typical application | Hobby / small devices | Bulk supply, drones, backup systems |

| BMS & protection | Minimal | Per-cell monitoring & balancing |

| Storage practice | Short term | 40–60% SOC, rotated, labeled |

| Price focus | Lowest unit cost | Reliability + traceability for wholesale buyers |

| Test reports | Often absent | Request IEC/UL/third-party test reports |

(Use this table on product pages to guide procurement teams.)

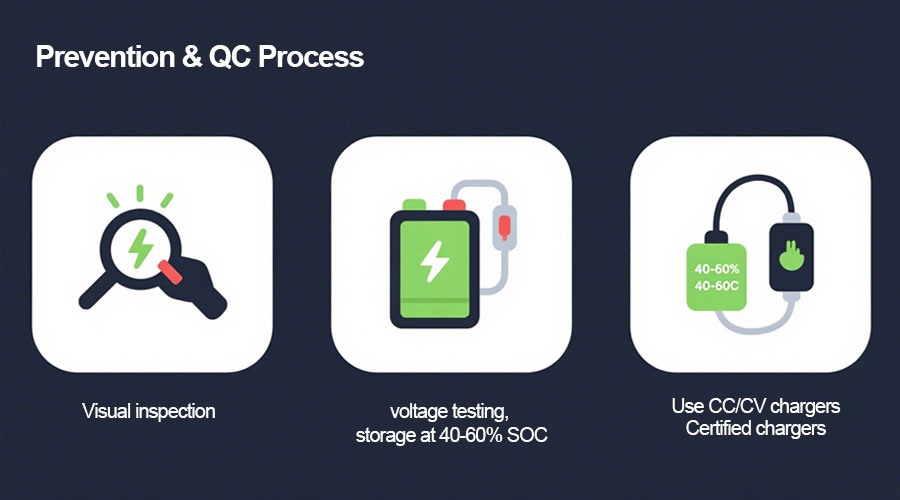

6-step prevention & incoming QC (actionable)

- Visual inspection on arrival. Check for dents, ruptures, or bulging. Quarantine suspect cartons.

- Measure cell voltages. Record per-cell voltages and attach photos. Keep logs for traceability.

- Store at 40–60% SOC. Store cool and dry. Label storage date and batch. (Per storage best practice.)

- Use certified CC/CV chargers. Chargers must cut off at proper voltage and support temperature sensing.

- Require BMS with per-cell balance. For bulk packs insist on active/passive balancing and fault logs. UL and industry guidance stress robust manufacturing controls.

- Train staff & prepare disposal route. Everyone should know emergency handling and recycling partners. iFixit and university safety pages give safe-handling steps.

Side note: If you buy wholesale lipo batteries, request a sample test batch before full acceptance. It saves headaches.

What to do if a cell is swollen (emergency steps)

· Stop charging. Power down the device. Do not puncture the pack.

· Move to a safe area. Ventilated, away from combustibles.

· Contact a certified recycler. Do not throw batteries in the trash. Official guidance and repair advice are clear: treat swollen packs as hazardous.

Common misconceptions (warning)

· “A little swelling is fine.” — False. Any swelling signals failure.

· “Cheap chargers work OK sometimes.” — Wrong. Inconsistent cutoffs cause overcharge.

· “Full charge for storage is better.” — Nope. High SOC accelerates ageing. Therefore, insist on proper specs.

Practical checklist (copy-paste; printable)

· Inspect cartons for damage on receipt.

· Run per-cell voltage checks and save logs.

· Store at 40–60% SOC; rotate stock monthly.

· Use certified CC/CV chargers with temp cutoffs.

· Ensure BMS with per-cell balancing on all bulk packs.

· Quarantine and properly dispose of swollen packs via certified recycler.

If you buy wholesale lipo batteries, request test reports, batch traceability, and a sample inspection. Need a ready PDF checklist and supplier audit template? Download our free QC pack or contact Himax for sample testing.