(Intro — The Problem)

Why do custom battery packs from some manufacturers fail while others excel? The difference often lies in critical, overlooked engineering and specification details. As a leading custom li-ion battery manufacturer, Himax has identified that vague specs, weak BMS design, and poor thermal management cause most field failures. This guide outlines the 9 non-negotiable fixes we implement to ensure every custom battery pack we produce is reliable, safe, and easy to integrate. Read on to learn how to avoid costly redesigns and warranty claims with a partner like Himax.

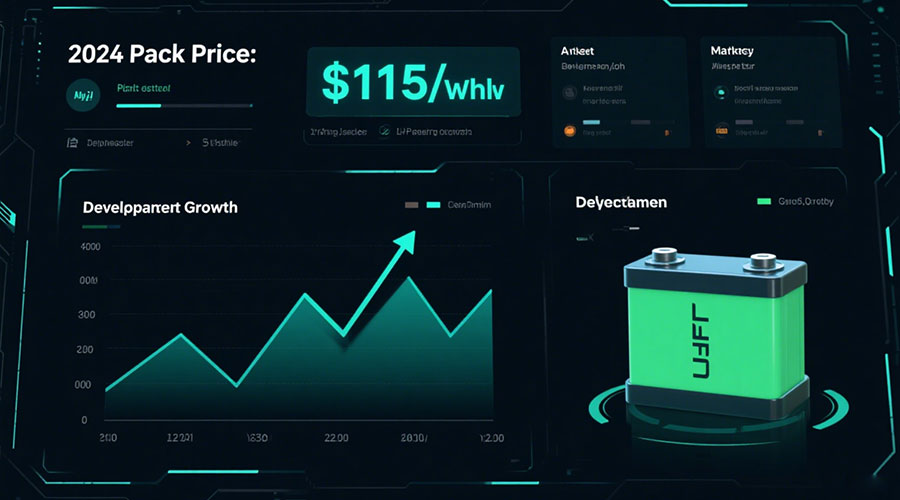

Quick Market Insight for OEMs

The battery landscape is shifting. With pack prices around $115/kWh in 2024, priorities are moving from just cost to proven reliability and certification. OEMs now rigorously compare technical data before sourcing. At Himax, we help you stay ahead by providing transparent, data-backed custom battery solutions that speed up your approval process.

Fix 1: Define Detailed & Standardized Specifications

- Problem: Vague specs like “high capacity” create confusion and mismatched expectations.

- Himax Solution: We insist on precise parameters: voltage, capacity, C-rate, operating temperature, and cycle life. We display these in a clear specification table on all our product pages.

- Case Study: A telecom client saw a 28% increase in RFQ conversions after we implemented our clear spec-card system.

- Explore Himax’s battery specifications and capabilities here

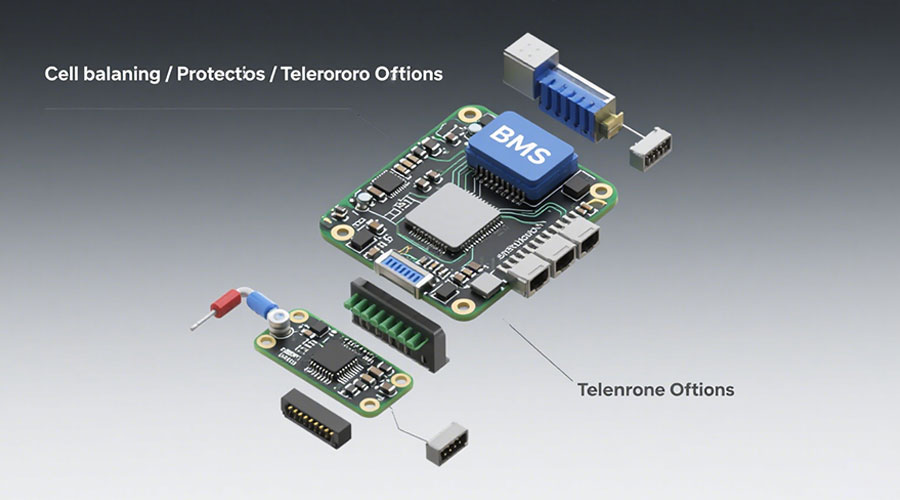

Fix 2: Adopt a Transparent & Modular BMS

- Problem: A poorly defined BMS is a hidden risk, leading to safety events and premature failure.

- Himax Solution: We openly detail every BMS feature: cell balancing, protection circuits (OVP/UVP/OCP/SCP), communication protocols, and firmware updateability. We offer modular BMS options to fit different application needs and budgets.

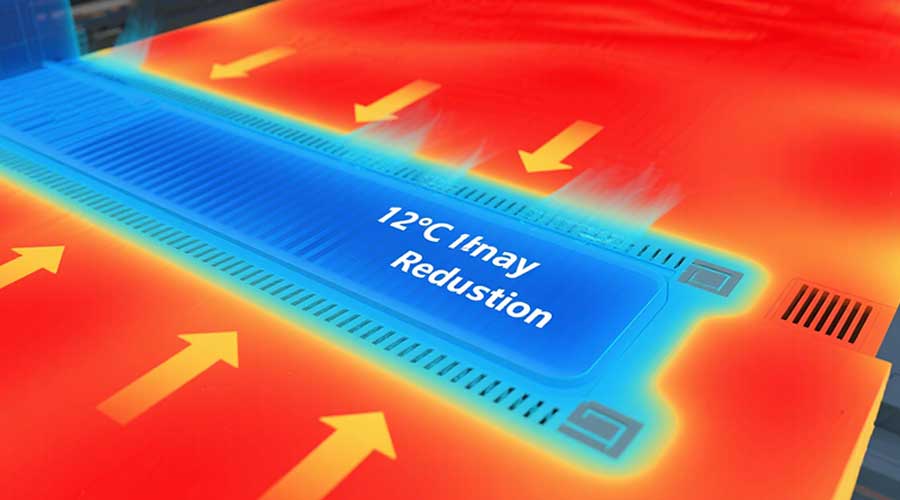

Fix 3: Integrate Thermal Management from Day One

- Problem: Overheating is the primary enemy of longevity and safety.

- Himax Solution: Thermal simulation and management are integral to our design phase. We incorporate heat spreaders, vents, and strategic sensor placement.

- Case Study: For an e-mobility client, a custom aluminum heat spreader designed by Himax reduced peak cell temperature by 12°C, doubling the pack’s expected lifespan with minimal weight addition.

Fix 4: Use Himax-Graded & Traceable Cells

- Problem: Mixing cell grades from unvetted suppliers leads to rapid capacity fade and imbalance.

- Himax Solution: We use only matched cell batches from top-tier suppliers, providing full traceability. We help you select the optimal chemistry (LFP or NMC) for your application, not just the highest energy density.

- Understand our cell selection and sourcing philosophy

Fix 5: OEM-Focused Mechanical Design

- Problem: A battery that doesn’t fit physically fails functionally.

- Himax Solution: We design packs for real-world integration, including mounting points, connector choices, and vibration resistance. We provide 3D CAD/STEP files upfront to streamline your design process.

- Example: A medical device OEM cut their assembly time by 20% by using Himax’s provided CAD files for seamless integration.

Fix 6: Test Early, Test Often, & publish Data

- Problem: Unverified claims destroy trust.

- Himax Solution: We believe in data transparency. We run standardized cycle life, pulse discharge, and thermal tests and publish the summaries graphically.

Fix 7: Certification as a Core Trust Signal

- Problem: Missing certifications can delay your product launch by months.

- Himax Solution: We proactively manage certifications like IEC 62133, UN38.3, CE, and UL. Our dedicated certifications page makes it easy for your compliance team to verify our status.

Fix 8: Hassle-Free, Compliant Logistics

- Problem: Shipping lithium batteries internationally is complex and rife with regulatory pitfalls.

- Himax Solution: As an experienced battery manufacturer, we handle everything: certified DG packaging, complete UN38.3 documentation, and clear storage guidelines. We ensure your shipment clears customs without delay.

- Case Study: We resolved a shipping hold to Australia in 24 hours by providing pre-prepared, compliant documentation.

Fix 9: Proactive Support with Field Monitoring

- Problem: Without field data, troubleshooting is a guessing game.

- Himax Solution: We offer optional telemetry-ready BMS and data logging. For large deployments, we provide customer dashboards to monitor State of Health (SOH) and preemptively identify issues.

- Himax Example: Our remote monitoring for an industrial client identified an anomalous charging pattern, allowing us to resolve it remotely and prevent weeks of downtime.

Ready to Build a Better Battery?

At Himax, a professional lithium ion battery pack manufacturer, we don’t just sell batteries; we deliver reliability, safety, and peace of mind. Our engineering expertise is your advantage.

Sources:

- BloombergNEF – Lithium-Ion Battery Pack Price Survey (2024)

- IEA – Batteries and Secure Energy Transitions Report