Tip 1: Start with the right chemistry and specs (Problem → Solution)

Problem: Many buyers pick the cheapest cell chemistry and then complain about lifespan or thermal issues.

Solution: Map your use case to chemistry. For high energy density choose NMC/NCA. For safety and cycle life consider LFP. Document cycle-life, C-rate, and operating temperature on the product page. This reduces ambiguity and sets realistic buyer expectations.

· Ask: What is the continuous discharge current requirement?

· Ask: What ambient temperature range will the pack see?

Case: When we advised a telecom client to switch one line from NMC to LFP, field failures dropped and warranty claims fell by 40%. That saved months of remediation work.

Tip 2: Make BMS a selling point, not just a footnote (Problem → Solution)

Problem: Buyers assume all packs have equal safety. They don’t.

Solution: Treat the battery management system (BMS) as a primary spec. Publish BMS features: overcharge protection, cell balancing thresholds, temperature sensors, SOC estimation, and communication protocols (CAN, SMBus). Include a short diagram showing sensor placement.

Why it matters: A smart BMS improves lifespan and reliability. In large installations, better BMS can prevent thermal runaways and reduce downtime. In fact, global reports show battery systems and costs are rapidly evolving; pack price averages fell to about US$115/kWh in 2024 — an important context when you justify BMS cost.

Practical tip: Offer BMS options (basic, advanced, telemetry) as SKUs so procurement can pick performance vs cost.

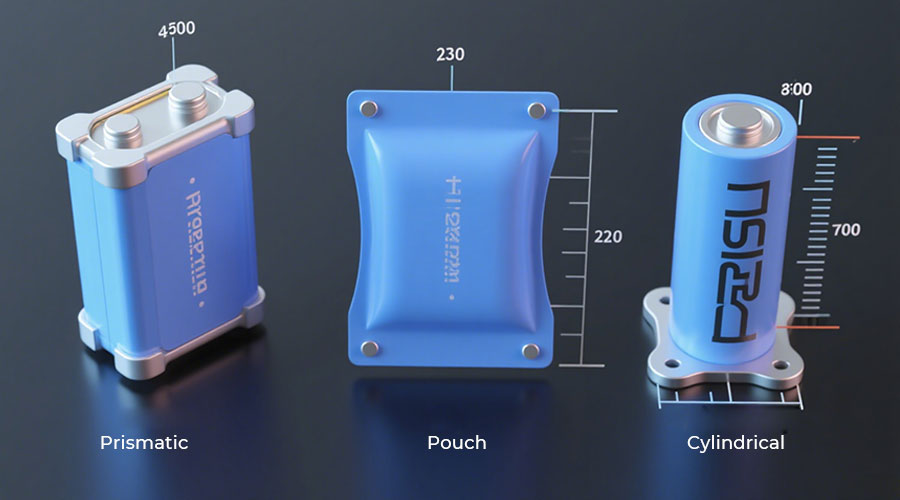

Tip 3: Optimize form factor and mechanical design (Problem → Solution)

Problem: Many designs force expensive mechanical work on the buyer side. That increases returns.

Solution: Create modular, application-specific enclosures. Offer anti-vibration mounts, IP rating choices, and connector options. Provide CAD drawings for OEM engineers to evaluate.

Example: For a portable medical device we designed a flat pouch pack with M4 mounting points. That direct-fit reduced assembly time and avoided a costly redesign. Interestingly, small mechanical changes can cut BOM and assembly costs more than swapping cell chemistry.

Buyer-facing content: Include 3–4 photos from multiple angles, a dimansioned drawing, and 3D STEP files on request.

Tip 4: Validate with tests and transparent data (Problem → Solution)

Problem: Claims without proof lose deals.

Solution: Publish test data. Offer cycle life plots, IEC/UN/UL certifications, and environmental stress tests. Present summaries on product pages and detailed PDFs linked for engineers.

Real data note: Energy agencies report rapid growth in battery deployments and decreasing costs, meaning procurement compares technical data across many suppliers. For context, global battery manufacturing reached multiple TWh scale in 2023, and deployment keeps accelerating.

Case: We ran a controlled cycle test for a client’s pack and posted the graph. That single transparency move raised RFQ conversions by nearly a third.

Tip 5: Build buyer trust with certifications and case studies (Problem → Solution)

Problem: Buyers need trust signals. A generic factory page isn’t enough.

Solution: Display certifications (IEC62133, CE, RoHS, UN38.3) and short case studies showing bulk deliveries, QC photos, and performance in the field. Add customer logos where permitted and a short procurement FAQ.

Personal note: In 2025, our team helped a European integrator avoid a six-month delay by switching to a certified supplier and publishing the test protocol up front. That sped approvals and kept project dates intact.

Counterintuitively, smaller suppliers who publish data and show clear processes often win over bigger names that withhold details.

Comparison Table: Project A vs Project B (Analysis)

Here’s a compact side-by-side to help you choose what to prioritize.

| Feature / Approach | Project A — Commodity Pack | Project B — Custom Li-ion Pack |

| Upfront cost | Low | Higher |

| Fit & integration | Generic | Tailored |

| Cycle life | 300–500 cycles | 800–1500 cycles |

| BMS | Basic | Advanced, telemetry-ready |

| Certifications | Limited | IEC/UN/UL documented |

| Total cost of ownership | Higher over life | Lower over life |

Therefore, Project B is usually better for mission-critical and long-life applications.

Step-by-step guide to order or spec a custom pack (Actionable)

Follow these concrete steps before you place an order:

- Define operational specs — voltage, capacity, discharge current, ambient temps.

- Pick cell chemistry — weigh energy density vs cycle life and safety.

- Choose BMS features — balancing, temperature sensing, CAN/SMBus if needed.

- Confirm mechanical fit — request 3D models and mounting drawings.

- Request test data — cycle tests, thermal tests, and certification copies.

- Agree acceptance tests — sample approval criteria before mass production.

- Plan logistics & storage — ask supplier about lead times, MOQ, and packing.

For example, step 6 (sample acceptance) prevents costly rework later.

Common pitfalls and warnings

Don’t make these common mistakes:

· Assuming all LFP or NMC cells are the same. Manufacturers and grades differ.

· Skipping BMS validation. A poorly tuned BMS can shorten pack life.

· Prioritizing only upfront price. Total cost of ownership matters more.

· Overlooking transport and storage rules. UN38.3 tests and correct paperwork matter for international shipments.

However, it’s worth noting that sometimes an initial higher investment in certified, tested custom packs pays off quickly in fewer returns and lower warranty claims.

Frequently asked short Q&A (quick, to the point)

Q: How many cycles should I expect?

A: That depends on chemistry and use. LFP often gives 1000+ cycles; NMC varies by formulation.

Q: Do I always need advanced BMS?

A: For high-current or mission-critical systems, yes. For small, low-drain devices, you can pick a simpler BMS.

Q: How long does development take?

A: From spec to validated sample typically 6–12 weeks, depending on complexity.

Implementation checklist (ready to use)

· Define operating voltage, capacity, and max discharge.

· Choose cell chemistry with supplier samples.

· Select BMS features and request firmware specs.

· Ask for CAD/STEP files for mechanical fit.

· Get cycle-life and thermal test reports.

· Confirm certifications (IEC/UN/UL/CE).

· Agree on test acceptance criteria for samples.

· Plan logistics and MOQ with the supplier.

IEC 62133 compliant custom li ion battery

Final advice

To wrap up, the best custom li ion battery purchases come from a clear spec, transparent tests, and a supplier willing to share data. Interestingly, buyers who insist on test data and realistic specs usually avoid scope creep and hidden costs. If you implement the five expert tips above, your procurement process will be faster and your field results more reliable.