Quick summary (read first)

If you’re buying batteries for baby monitor products at scale, you must treat batteries as both a safety and a sourcing problem. Your procurement checklist should prioritize (1) the right chemistry for the device (NiMH, Li-ion or LiPo), (2) safety & certification (IEC 62133, UN38.3 and market-specific approvals), (3) robust sample testing before mass production, and (4) transportation & packaging that meets IATA/IMDG rules. This guide walks you from RFQ to receiving palletized product — with templates and pass/fail criteria you can use immediately.

Why batteries are procurement-critical for baby monitors

Batteries are the single component most likely to cause returns, regulatory headaches, or — worst case — a safety incident. Video-enabled smart monitors typically require compact Li-ion or LiPo packs for high energy density; simpler parent units or legacy units often use AA/AAA NiMH cells or NiMH packs. Choosing the wrong chemistry, accepting an uncertified batch, or misunderstanding transport rules will cost you time, money and reputation. (See chemistry differences below.)

Key takeaways for procurement teams

– Demand certificates up front: IEC 62133 (safety), UN38.3 (transport test summary) and market-specific marks (e.g., CE/UKCA, UL) as applicable. IEC 62133 — Battery safety standard (lithium & NiMH safety tests)

– Require supplier traceability: batch IDs, cell vendor, and a per-lot QC report.

– Insist on a formal sample acceptance process (SIR) before approving mass production.

– Build transport compliance into your contract — Li-ion shipments will likely require special handling and SOC limits.

1) Procurement terms & sample inspection — must-have contract language

Below is a compact set of procurement clauses and a step-by-step sample inspection protocol you can paste into a Purchase Order or RFQ.

Recommended contract clauses (copy/paste format)

- MOQ & Price Ladder: “MOQ: [X units]. Price tiers: 1–X units = $A/unit; X+1–Y = $B/unit; Y+ = $C/unit.”

- Lead Time: “Sample lead time: XX working days from RFQ sign-off. Mass production lead time: XX–YY working days from receipt of deposit and approved SIR.”

- Payment Terms: “30% deposit at order, 70% balance before shipping (or L/C at sight).”

- Quality & Warranty: “Minimum 12-month warranty from shipment date. Supplier to replace or credit defective units failing agreed QA within 30 days of claim.”

- Certification & Documentation: “Supplier must deliver scanned certificates and per-lot QC report: IEC 62133, UN38.3 test summary, RoHS, CE/UL (as applicable).”

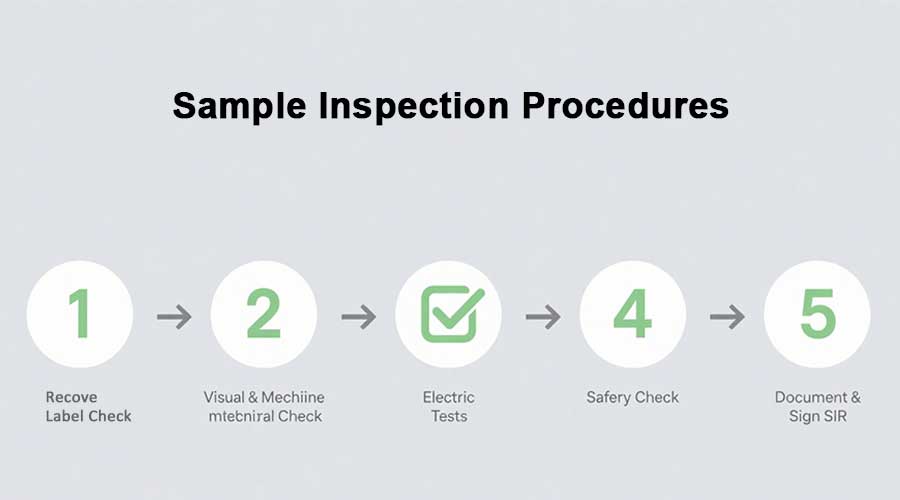

Baby monitor battery sample inspection & acceptance workflow (practical steps)

- Receive & label check: Verify model, lot number, manufacturing date and markings. Immediate reject if package is damaged, swollen or leaking.

- Visual & mechanical check: Look for dents, cracks, loose terminals, soldering problems or mis-labelled polarity.

- Electrical tests: Capacity test (discharge at agreed current to specified cutoff; capacity must meet ≥ 90% of nominal — set this in PO). Internal resistance: Value within supplier spec. Charge/discharge cycle test: sample 10 units for 3 cycles to verify performance.

- Safety checks: BMS functionality (overcharge/overdischarge/short-circuit response) and temperature rise under load (record Tmax).

- Document & sign SIR: If pass → sign Sample Inspection Report (SIR) and authorize production. If fail → NCR with corrective action timeline.

Tip: Put the SIR acceptance trigger (e.g., “Capacity ≥ 90% and no visible defects”) into the PO to avoid ambiguity.

2) Common quality issues & acceptance criteria (what to insist on)

When you receive a first mass shipment, use the following acceptance criteria and sampling approach.

Common failure baby monitor battery modes

- Capacity shortfall (cells deliver less than promised)

- High self-discharge (bad for batteries that sit in inventory)

- Physical defects (swelling, leaks, cracked terminals)

- BMS failure or false trips (overcharge/overdischarge protection not behaving)

- Connector / polarity mismatches (device incompatibility)

Sampling & acceptance (practical defaults)

Sampling plan: Use ISO 2859 / AQL approach or agree a practical rule: smaller orders (<5k) sample 50 pcs; larger orders sample 1% of units, minimum 50 pcs.

Acceptance thresholds (example): Capacity: ≥ 90% of rated capacity at contract-specified C-rate. Internal resistance: within supplier’s spec ±10%. Visual defects: 0% critical defects allowed (e.g., swelling, leakage).

Disposition: If sample fails, require root-cause, corrective action within 7–14 calendar days and a re-sample. If failures persist, negotiate unit credit or arrange rework/return.

3) Packaging & logistics — rules you cannot ignore

Batteries are regulated goods. Logistics issues are the most common friction point in international procurement.

Regulatory & transport highlights (must cite)

UN38.3 testing is the baseline requirement for lithium cells and batteries for transport; carriers commonly require a UN38.3 test summary or report per shipment.

Air transport (IATA) State-of-Charge (SoC): recent IATA guidance recommends (and will make mandatory in stages) that lithium-ion batteries offered for air transport be at ≤30% SOC, with stricter rules for certain categories; this affects packing and shipping timelines. Plan for SOC management and documentation.

Practical packaging checklist

- Cell isolation: Cover terminals or use insulating caps to prevent short circuits.

- Inner packaging: Individual compartments, anti-static/anti-shock inserts.

- Outer packaging: Strong corrugated boxes, palletized and shrink-wrapped. Mark boxes with required hazard labels when applicable.

- Documentation: UN38.3 summary, IEC 62133 certificate, SDS (safety data sheet), packing list and commercial invoice in each consignment.

- Carrier selection: Use carriers familiar with battery shipments (they’ll flag incorrect paperwork early). Ensure freight forwarder confirms whether the shipment is air-eligible or must go by sea.

4) How to ask for quotes (RFQ & BOM template)

To shorten supplier turnaround and get comparable quotes quickly, include this exact information in your RFQ email or procurement portal. Below is a one-page BOM template you can paste directly.

Short RFQ checklist (include in email subject & first paragraph)

- Product name & intended device (e.g., “Parent unit battery pack for Model X baby monitor”)

- Chemistry (NiMH / Li-ion / LiPo) and nominal voltage & capacity (e.g., “3.7 V, 2200 mAh”)

- Mechanical constraints (L×W×H in mm; max weight)

- Connector type and wire length (or request sample connector)

- BMS functions required (overcharge, overdischarge, short circuit, temp sensor, SMBus?)

- Certifications required (IEC 62133, UN38.3, RoHS, CE/UL if needed)

- Sample quantity & expected sample date (e.g., 3 working samples in 10 business days)

- Target first PO qty and annual forecast (used to calculate price ladder)

- Packing requirements, FOB/CIF port and Incoterms, preferred payment terms

BOM template (table you can paste into spreadsheet)

| Field | Example / Notes | Your Value |

| Product name | Baby Monitor parent unit battery pack | |

| Chemistry | Li-ion / NiMH / LiPo | |

| Nominal voltage | 3.7 V | |

| Nominal capacity | 2200 mAh | |

| Cell model / vendor | cell part number or vendor name | |

| Configuration | 1S2P (1 series × 2 parallel) | |

| Dimensions (mm) | 70 × 22 × 12 | |

| Weight (g) | 45 | |

| Connector / wire | JST-PH 2P, 150 mm AWG22 | |

| BMS spec | OVP, ODP, short circuit, temp sensor | |

| Certifications | IEC 62133, UN38.3, RoHS, CE | |

| Sample qty | 3 | |

| MOQ | 1,000 pcs | |

| Lead time (sample / mass) | 10 days / 30 days | |

| Target annual qty | 60,000 pcs | |

| Packaging | 100 pcs per box, palletized | |

| Price term | FOB Shenzhen | |

| Payment | 30% deposit, 70% before shipment | |

| Notes | Serialized lot numbers required |

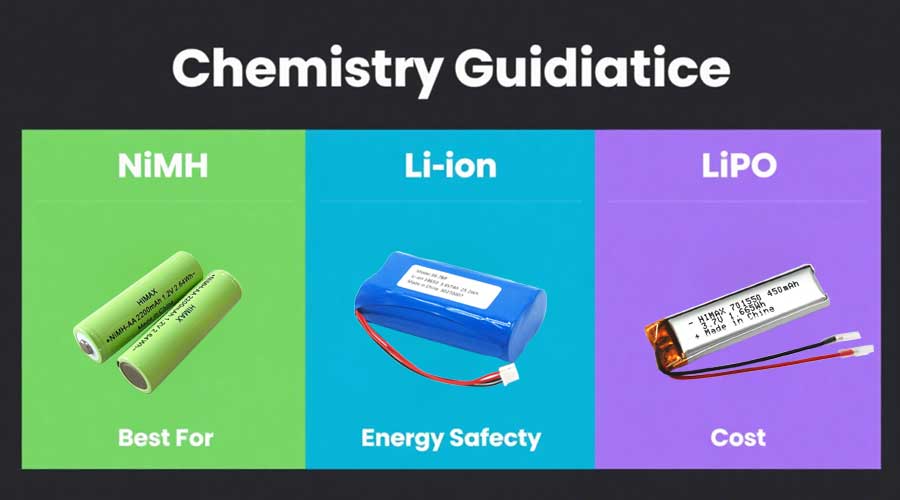

Chemistry guidance: which chemistry for which baby monitor battery

NiMH: Great for AA/AAA parent units and legacy models where size/weight are less critical. Safer handling and often a lower price point; good choice for replaceable battery packs.

Li-ion / LiPo: Higher energy density (smaller, lighter packs) and the norm for video-enabled and always-on smart monitors. Requires stricter packaging, BMS and transport controls.

If you aim to cover the whole market, specify both NiMH and Li-ion/LiPo SKUs in your RFQs — vendors like Himax can supply multiple chemistries or offer cross-sourcing options.

Quick checklist you can paste into any RFQ (one-line)

Certificates (IEC 62133, UN38.3), Sample SIR, MOQ, per-lot QC report, Lead time (sample / mass), Packing & UN labeling, Warranty (12 months), Payment terms.

FAQ (for procurement teams)

- What certificates are mandatory for selling into EU/US?

- At minimum, show IEC 62133 for cell/battery safety and UN38.3 test summary for transport. Additional CE/UKCA/UL or EMC approvals may be required for the finished device — check local market rules.

- What is an acceptable baby monitor battery sample lead time?

- Typical sample lead times are 7–20 working days. Agree this in the RFQ and confirm any tooling or custom connector lead times.

- How low should capacity tolerance be?

- A practical acceptance threshold is ≥90% of rated capacity under contract-defined C-rate — but set this explicitly in your PO or SIR.

- How do transport SOC rules change my shipping?

- IATA guidance now recommends (and will mandate in stages) offering lithium batteries at ≤30% SOC for air transport; plan for charge/discharge or ground transport accordingly.

- Who is responsible for transport compliance — buyer or seller?

- Define in Incoterms. Often suppliers prepare compliant packaging and documentation, but buyers should confirm carrier acceptance and any local import rules.

- What should be on the per-lot QC report?

- Batch number, cell vendor, capacity test results (CSV), internal resistance readings, date code, and pass/fail summary for visual and safety checks.

Closing / CTA

If you want a supplier that: (a) offers NiMH, Li-ion and LiPo production; (b) provides IEC 62133 and UN38.3 documentation; (c) accepts sample SIRs and executes small pilot runs before mass production — Himax can provide a one-stop solution with factory pricing, customizable pack options and B2B packaging. Contact our procurement team with your completed BOM (paste the table above) and we will return a formal RFQ within 48 hours.

Email: sales@himaxbattery.com | WhatsApp: [+region number] | Request: attach your BOM, target annual qty and preferred Incoterm.

Sources & further reading

- CPSC guidance on button/coin batteries and product obligations (Reese’s Law).

- IEC 62133 battery safety standard — overview & testing for rechargeable cells.

- UN Manual of Tests and Criteria (sub-section 38.3) — required tests for transport.

- IATA Lithium Battery Guidance — state-of-charge and air transport requirements.

- Practical chemistry overview (NiMH vs Li-ion).