Introduction and Audience Focus

As OEMs and product engineers in the smart pet wearable market, you know that battery performance can make or break user satisfaction. This deep-dive explores the technical parameters, customization strategies, and certification processes essential for designing reliable, long-lasting batteries for smart pet collars, GPS trackers, and health monitors.

1. Market and Application Requirements

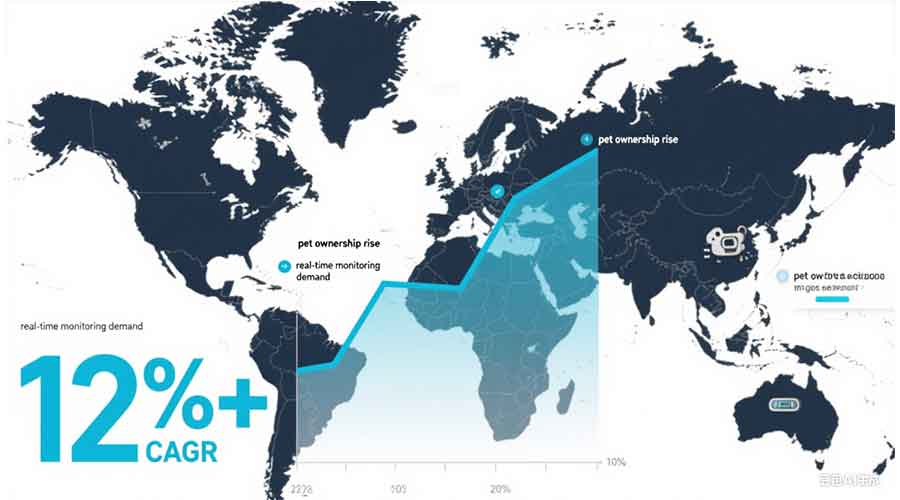

1.1 Global Market Trends

The smart pet wearable sector is projected to grow at a 12%+ CAGR over the next five years, driven by rising pet ownership and increasing demand for real-time health and location monitoring. Manufacturers must therefore optimize for size, weight, and power to stay competitive.

1.2 Scenario-Specific Performance Metrics

– Indoor Smart Collars: Prioritize miniaturization and comfort. Target energy densities ≥ 250 Wh/L to achieve 5–7 days of standby life in a compact form factor.

– Outdoor GPS Trackers: Emphasize peak discharge and weather resistance. Design for burst currents up to 5 A and IP67/IP68‐rated housings to withstand dust and submersion.

1.3 Key B2B Procurement Drivers

Cost per watt-hour, consistent quality, and rapid prototyping capability top the list. Offering MOQ flexibility, transparent lead times, and design validation support will accelerate OEM adoption.

2. Core Technical Deep Dive

2.1 Cell Chemistry and Form Factor

– Lithium-Ion vs. LiFePO₄ vs. Solid-State: LiFePO₄ offers superior cycle life (> 3,000 cycles) and thermal stability, while lithium-ion provides higher volumetric energy density. Solid-state remains emerging but promises thin, flexible packs.

– Form Factor Choices: 18650 cylindrical cells balance maturity and cost, whereas prismatic and pouch cells enable slimmer profiles.

2.2 Multi-Stage BMS Features and Algorithms

– Fault Detection: Integrate MOSFET short-circuit sensing, over-temperature and under-voltage monitoring. Implement auto-shutdown routines within < 10 ms of anomaly detection.

– Charge/Discharge Management: Dynamic “active” vs. “sleep” mode switching based on motion sensors conserves energy. Algorithms can reduce idle-mode current draw to < 10 µA.

– Communication Interfaces: Offer CAN for industrial trackers, SMBus for standard battery packs, or UART for custom firmware integration.

2.3 Thermal Management and Safety Design

– Temperature Sensing Layout: Position NTC sensors near cell centers and pack edges to capture hotspots.

– Heat Dissipation: Use aluminum heat spreaders or thin graphite sheets to channel thermal energy away from sensitive electronics.

– Hardware Protections: Include PTC fuses, reverse-polarity diodes, and transient voltage suppressors on input lines.

3. Customization Best Practices

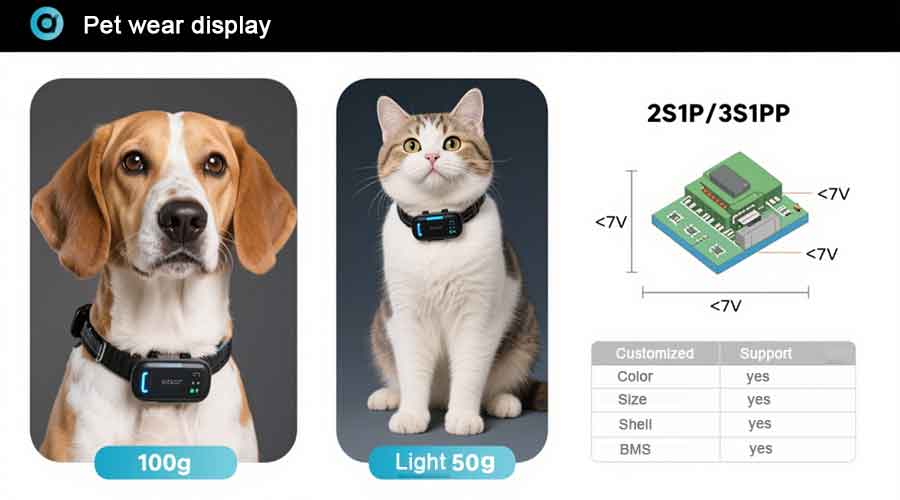

3.1 Size, Weight, and Ergonomics

– Pet-Specific Cases: Dogs may accommodate up to 100 g additional weight; cats typically ≤ 50 g. Tailor cell count and casing materials (e.g., lightweight ABS or PC+GF).

– Module Architecture: Consider 2S1P or 3S1P layouts for < 7 V systems, balancing voltage headroom with compactness.

3.2 Waterproofing and Dustproofing (IP67/IP68)

– Seal Selection: Employ silicone O-rings rated for repeated flex cycles.

– Potting Compounds: Use low-ionic epoxy resins to encapsulate BMS boards without compromising signal transmission.

– Validation Protocols: Perform 72-hour salt-spray tests and multiple ingress cycles per IEC 60529 guidelines.

3.3 Connectors and Harness Integration

– Standard vs. Custom: JST PH series is cost-effective, Molex MicroLock offers higher mating cycles.

– Strain Relief: Design molded strain-relief boots to protect solder joints from tugging stresses.

4. Certification and Compliance Workflow

4.1 Safety Standards

– IEC 62133-2: Mandatory for international markets—focus on overcharge, forced discharge, and mechanical abuse tests.

– UL 1642: North American baseline for single‐cell safety.

– UN 38.3: Required for air transport—thermal, vibration, and shock testing.

Tip: Begin sample submission six weeks before launch to accommodate retest allowances.

4.2 Wireless and EMC Regulations

– Bluetooth SIG: Pre-certified modules can cut six months off development time.

– EMI/EMC: CISPR 32 Class B compliance demands ≤ 40 dBμV/m at 10 m; incorporate EMI gaskets and ferrite beads on data lines.

– Regional Differences: FCC Part 15 for the U.S., RED (2014/53/EU) for Europe—plan dual-region test campaigns. Battery Management for Wearable Electronics (TI Application Note SLUA618)

5. Case Studies and Cost Modeling

5.1 Comparative OEM Solutions

| Feature | Solution A | Solution B | Himax Custom Pack |

| Chemistry | Li-ion (18650) | LiFePO₄ pouch | LiFePO₄ cylindrical |

| Capacity | 2,600 mAh | 3,000 mAh | 2,800 mAh |

| BMS | Basic over-voltage | Firmware-controlled | Multi-stage, CAN/SMBus |

| IP Rating | IP54 | IP67 | IP68 |

| MOQ | 5,000 units | 2,000 units | 500 units |

Himax offers flexible chemistry and IP68 rating with lower MOQ.

5.2 Cost Breakdown (per unit at 1k MOQ)

– Cell materials: 35%

– BMS & electronics: 25%

– Housing & seals: 15%

– Certification & testing: 10%

– Assembly & QA: 15%

5.3 Supply Chain Resilience

Maintain dual‐sourced cells from Tier 1 vendors and hold 6–8 weeks of finished goods inventory to absorb lead‐time fluctuations.

6. Future Technologies and Trends

6.1 Solid-State and Flexible Batteries

Promises ultra-thin, conformal packs—ideal for collars that wrap around curved profiles. Early prototypes show energy densities > 300 Wh/L.

6.2 Energy Harvesting Integration

– Solar Assist: Incorporate micro-solar panels on collar exteriors to extend run time by 10–15%.

– Kinetic Charging: Piezoelectric elements can recoup movement energy, topping off cells during active play.

6.3 AI-Driven Battery Management

Cloud-connected BMS platforms can predict cell aging and stream firmware updates, reducing in-field failures and warranty costs.

Conclusion and Next Steps

Designing the ideal battery for smart pet wearables requires a holistic approach—balancing chemistry, form factor, BMS sophistication, and compliance. Himax offers end-to-end customization from cell selection through certification, with flexible MOQs and rapid prototyping support.

Ready to Develop Your Next-Gen Pet Wearable Battery?

Contact our engineering team for a free feasibility study and accelerated custom battery proposal. Reach out via services@himaxelectronics.com or complete our ▶ One-Click Customization Form to get started.