In today’s automated world, your robot-battery must deliver reliable power, safety, and long life. A custom-lifepo4-battery-pack designed around an advanced robot-battery-bms and predictive maintenance not only maximizes uptime but also simplifies fleet management. In this guide, we’ll show you how to combine smart monitoring, data-driven alerts, and optimized robot-battery-thermal-management to keep your robots running at peak performance.

1. Intelligent Robot-Battery-BMS Hardware & Modular Design

· Choosing the Right SoC

Leading BMS SoCs from TI, Cypress, or NXP form the core of your robot-battery-bms.

· Centralized vs. Distributed Topologies

o Centralized BMS suits small packs—simple wiring, lower cost.

o Distributed BMS places monitoring nodes every few cells, ideal for large custom-lifepo4-battery-pack arrays with superior noise immunity.

· Modular, Hot-Swap Design

Himax’s plug-and-play BMS modules let you mix 24 V, 48 V, or higher packs without redesign—perfect for AGVs, drones, and service robots.

2. Communication Protocols & Fleet Integration

· CAN-bus vs. SMBus vs. Modbus

o CAN-bus: High throughput, real-time diagnostics for multi-pack robot fleets.

o SMBus: Cost-effective for lighter-duty systems.

o Modbus: Seamless PLC/SCADA integration for industrial lines.

· Hierarchical Networking

Segment your fleet’s robot-battery packs into zones to balance bus load and prevent data collisions.

· API Interfaces

Standard RESTful and MQTT endpoints allow quick integration with ROS, PLCs, and cloud dashboards.

3. Multi-Dimensional Data & Health Assessment (SoC/SoH)

· Key Metrics

The robot-battery-bms continuously logs cell voltage, pack current, temperature, and internal resistance—essential for condition monitoring.

· SoC Estimation

Combining coulomb counting with extended Kalman filtering ensures accurate State-of-Charge readings under dynamic loads.

· SoH Diagnosis

Hybrid models (electrochemical + machine learning) predict capacity fade, so you know when to plan maintenance.

4. Predictive Maintenance Strategy

· Fault Mode Detection

Recognize sudden capacity drops, internal resistance spikes, and temperature anomalies before they escalate.

· Remaining Useful Life (RUL) Prediction

Leverage cycle-history and SoH trends to forecast when your custom-lifepo4-battery-pack will reach end-of-life—avoiding unexpected downtime.

· Automated Alerts & Recommendations

The system pushes maintenance tickets—cell replacement, balance board check, or full-pack swap—directly to your operations team.

5. Robot-Battery-Thermal-Management Techniques

· Passive Cooling

Heat sinks, phase-change materials, and thermal interface pads keep LiFePO₄ cells within safe temperature bands.

· Active Cooling

Liquid loops or forced-air fans handle sustained high-current discharge in heavy-duty robots.

· Thermal Layout Optimization

Simulation-driven placement ensures uniform heat dissipation across your custom-lifepo4-battery-pack.

6. Cloud Platform & Visualization

· Edge Gateway Architecture

Secure MQTT/WebSocket links feed real-time robot-battery data to the cloud.

· Control-Room Dashboards

Visualize health scores, energy usage, and alarm history for your entire fleet.

· Mobile & Email Alerts

Critical notifications ensure maintenance teams respond before failures occur.

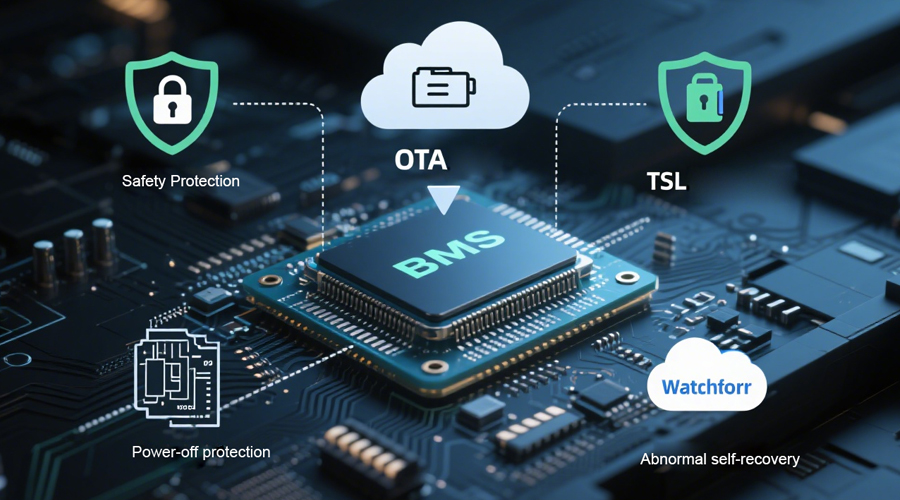

7. Security & Firmware Management

· Secure OTA Updates

Cryptographically signed, differential firmware packages keep your robot-battery-bms up to date—with zero downtime.

· Network Encryption

TLS and optional VPN tunnels protect data in transit; device authentication prevents unauthorized access.

· Fail-Safe Design

Hardware watchdogs and power-loss protection circuits guarantee safe operation even during network or power interruptions.

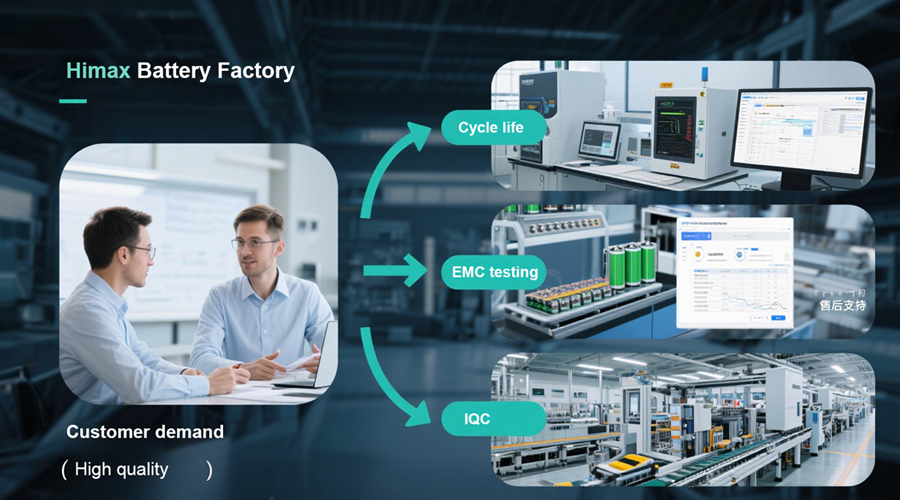

8. Himax Custom Service Workflow

1. Requirement Analysis

Define pack voltage, capacity, and form factor for your robot platform.

2. Prototype & Testing

Our lab runs cycle life, extreme temperature, and EMC tests—delivering a full performance report.

4. Volume Production & Support

With stringent incoming-material checks, process controls, and dedicated after-sales, Himax ensures on-time delivery and ongoing reliability.

9. Success Stories & Impact

· AGV Fleet: Implementing an intelligent BMS and predictive maintenance cut unplanned downtime by 30%, raising fleet utilization by 20%.

· Service Robots: Our custom LiFePO₄ battery pack with optimized thermal management extended battery life by 25% and reduced maintenance costs by 20%.

By combining a tailored custom-lifepo4-battery-pack, an advanced robot-battery-bms, and data-driven predictive maintenance—backed by robust robot-battery-thermal-management—Himax delivers the reliable power your robots demand. Ready to transform your fleet’s uptime? Contact Himax today!