The Rise of LiFePO4 Prismatic Cells: Why 3.2V Batteries Are Powering the Future

In the ever-evolving landscape of energy storage, the choices we make about battery technology can define the success or failure of entire projects. As engineers, installers, and decision-makers, we’ve all felt the pressure of balancing performance, safety, cost, and longevity when recommending or specifying a system. Over the past decade, lithium iron phosphate (LiFePO4) chemistry has steadily emerged as a leader for applications that demand both reliability and cycle life—and within that chemistry, prismatic-format cells have quietly become a go-to for commercial, industrial, and residential energy solutions. At Himax Battery, we’ve spent thousands of hours working side-by-side with clients across Europe, North America, and beyond to design, test, and deploy hundreds of LiFePO4 prismatic battery packs. Along the way, we’ve learned what really matters when choosing a “3.2V LiFePO4 battery” or a bank of “rechargeable 3.2V batteries,” and why models such as the 3.2V 100Ah, 280Ah, and 314Ah cells continue to top the bestseller lists.

If you’ve ever wrestled with the question of “Should I go cylindrical or prismatic?”—or “Is a 3.2V 280Ah prismatic cell really worth the premium?”—this article is for you. We’ll speak candidly about the technical trade-offs, share real-world stories from clients who’ve been burned by outdated specs, and explain how our hands-on approach can help you avoid pitfalls. By the end, you’ll see why LiFePO4 prismatic cells are not just another buzzword, but a genuine game-changer for anyone looking to build a robust, long-lasting energy system.

1. A Personal Perspective: Why We Began Embracing Prismatic Cells

When we first started Himax’s LiFePO4 division around 10 years ago, lithium-ion batteries were already ubiquitous in consumer electronics. But for larger-scale energy storage—solar arrays, telecommunications backup, electric vehicle (EV) charging stations—there was a nagging question: which form factor could deliver the safest, most space-efficient, and maintenance-friendly solution at scale?

Initially, many of our clients insisted on cylindrical cells—after all, 18650s (and later 21700s and 32700s) had proven themselves in laptops, power tools, and even early EVs. Their mechanical robustness and well-understood manufacturing processes gave buyers a sense of security. Yet as project scopes grew—from small solar home systems to multi-megawatt commercial installations—we noticed recurring pain points:

1. Wasted Volume & Inefficient Layouts

Even with tight robot-controlled assembly, cylindrical cells create air gaps and often require extra structural support or plastic packaging to hold them in place. For a pack meant to fit inside a tight cabinet or a prebuilt rack, that wasted volume translates directly into reduced overall energy per cubic meter or increased balance-of-system costs.

2. Complex BMS Integration

Hundreds or even thousands of individual cylinder cells mean far more voltage taps, sense lines, and wiring harness complexity. Each additional connection is a potential failure point—and when you’re looking at a mission-critical backup system, that adds up to more engineering headaches (and higher maintenance costs) than many clients are comfortable with.

3. Inconsistent Thermal Paths

While cylindrical cells do excel at individual heat dissipation, once you pack them tightly together, achieving consistent thermal management across every cell becomes tricky—especially at higher C-rates. Uneven heating can shorten cycle life and introduce safety concerns if not managed carefully.

In short, we found ourselves telling clients: “Yes, cylindrical cells can work well … but if you truly want the 3.2V LiFePO4 battery to last for 5,000 cycles and occupy a minimal footprint, consider prismatic cells instead.” Over time, more and more end-users—particularly those deploying for industrial and utility applications—heard that message and saw real-world results.

2. Anatomy of a Prismatic Cell: The Basics You Need to Know

Before we dive into comparative performance and real-life case studies, let’s clarify exactly what we mean by a “prismatic” LiFePO4 cell .

1. Outer Casing & Form Factor

– Shape : A prismatic cell is essentially a flat, rectangular (or slightly cuboid) package. Instead of winding layers of electrode jelly into a cylinder, the electrodes in a prismatic cell are laminated in a pouch or rigid metallic casing. This design drastically reduces wasted space compared to cylindrical models.

– Materials : Most high-quality LiFePO4 prismatic cells use aluminum-nickel alloy or coated steel for the external casing. Internally, thin stainless steel tabs are often used to collect currents from the electrode stacks.

2. Nominal Voltage & Chemistry

– LiFePO4 chemistry naturally provides 3.2 V nominal per cell. During charging, it peaks around 3.6–3.65 V, and under typical discharge, it goes down to about 2.5 V before users cut it off to preserve longevity. That nominal 3.2 V means combining four cells in series yields ~12.8 V—perfect for racks, RVs, telecom systems, and smaller EV platforms.

– Because LiFePO4 contains stable iron and phosphate structures, it is far less prone to thermal runaway than NMC, NCA, or LFP variants with cobalt, nickel, or manganese blends. In plain English: if you accidentally overcharge or your BMS fails, LiFePO4 is the “safest” of popular lithium chemistries.

3. Key Specifications to Evaluate

– Capacity (Ah) : We’ll look more closely at why 100Ah, 280Ah, and 314Ah prismatic cells consistently top our charts.

– Cycle Life : Most good-quality LiFePO4 prismatic cells deliver 3,000–5,000 cycles at 80% Depth of Discharge (DoD) . However, that figure can stretch to 6,000+ if you only discharge to 50% DoD.

– Internal Resistance & Heat Generation : Low internal resistance (typically 0.5–0.8 mΩ for a 100Ah cell, ~0.3–0.5 mΩ for bigger formats) translates into less heat and more power capability.

– Weight & Dimensions : With prismatic packaging, every millimeter counts. For instance, a 3.2 V 100Ah cell is typically around 330×170×52 mm and weighs about 3.8 kg. A 3.2 V 280Ah cell might measure 550×210×90 mm and weigh ~9.8 kg. Meanwhile, a 3.2 V 314Ah cell is roughly 615×220×90 mm and tips the scales at ~11 kg. We’ll dissect why those dimensions matter later on.

3. Space Efficiency & Modular Design: Prismatic Cells Win

Imagine you’re an installation engineer tasked with building a 48 V, 10 kWh solar-plus-storage system in a standard 19” rack. You have two options:

– Fill that rack with tens (or even hundreds) of cylindrical cells wired together, complete with plastic holders or adhesive strips to maintain spacing.

– Use principle-sized trays that hold exactly sixteen 3.2 V 100Ah prismatic cells in series-parallel, each tray fitting snugly into that same 19” footprint.

In our experience, the difference is staggering:

1. Higher Volumetric Energy Density

Four 3.2 V 100Ah prismatic cells in series give you roughly 12.8 V × 100 Ah = 1.28 kWh in a package that occupies about 0.029 m³ (29 liters). To get the same usable capacity from 18650 or 32700 cells, you often end up with ~40–50 liters of wasted space if you factor in the spacing and packaging required—especially if you want the pack to have proper airflow for cooling.

2. Simplified Pack Architecture

Normally, a cylindrical-cell pack with 12.8 V nominal would need (for 100 Ah capacity) upwards of 600–800 individual cells (depending on cell capacity). That’s hundreds of welds or spot joints and dozens of sense wires. In contrast, a prismatic pack might use just 16 cells in a fixed busbar arrangement. Fewer cells = fewer points of failure.

3. Ease of Expansion

Suppose six months later your customer wants to scale that 10 kWh system to 20 kWh. If you’re using prismatic modules, you design a second identical rack and simply bolt it next to the first. With cylindrical modules, you’ve got to redesign the entire holder system and make sure wiring harnesses—already at their length limits—don’t flick out or get snagged.

Over and over, our clients tell us: “We chose prismatic because the cabinets simply look cleaner, and it makes service visits so much faster.” Many end-users don’t appreciate how much wiring and spacing challenges eat into available rack height during the design phase—prismatic cells put those headaches behind you.

4. Thermal Management & Safety: Why LiFePO4 Shines

Any serious energy storage professional will tell you: “Safety beats density every day of the week.” When you’re working on an off-grid solar array in a desert environment (ambient temps > 45 °C) or a telecom cabinet in a basement with poor airflow, thermal stability can mean the difference between a perfectly reliable backup system and a cascading failure that leaves customers in the dark.

1. Intrinsic LiFePO4 Stability

– LiFePO4 chemistry doesn’t support the same rapid, energetic chain reactions that nickel-cobalt batteries can, so when abused, it’s far less likely to vent hot gasses or shift solids around the electrodes. In plain English, if you overcharge a LiFePO4 pack by 5–10% briefly, you’ll usually damage capacity but not trigger a full “thermal runaway.”

– We’ve personally tested cells at +60 °C ambient for days on end. The prismatic aluminum casing holds up, and voltage creep is minimal. Very few other lithium chemistries tolerate such abuse without derating.

2. Uniform Thermal Pathways

– A prismatic cell’s flat sides mean you can sandwich thin aluminum or graphite cooling plates around it, creating a consistent conduction path. We’ve designed systems where liquid cooling plates sit directly against six sides of a prismatic cell, keeping every part within 2 °C of each other, even under 0.5 C continuous discharge. That uniformity is nearly impossible to achieve in a cylindrical-cell array unless you surround every single cell in custom cooling channels (an expensive and labor-intensive solution).

– Enhanced safety features—like internal pressure relief valves, PTC (Positive Temperature Coefficient) resistive elements, and flame-retardant plastics—are easier to integrate into prismatic modules. For example, our 3.2 V 280Ah cells have a built-in microporous safety membrane that vents internally if the pressure spikes, preventing catastrophic ruptures.

3. Real-World Endpoint

A client in Southern Spain, running a pair of 50 kWh prismatic LiFePO4 strings to back up a small factory’s cleanroom assembly line, reported zero safety incidents over three years—even when ambient temps soared to 50 °C. Their colleagues who stuck with high-density cylindrical NMC packs had to deal with derating protocols in mid-summer, sacrificing uptime. It’s hard to understate how reassuring it is to specify a LiFePO4 prismatic system that operators trust without second-guessing.

5. Cycle Life & Total Cost of Ownership: Getting the Numbers Right

When evaluating major capital expenses—particularly for B2B projects— Total Cost of Ownership (TCO) often outweighs upfront cost in the long run. Most of our clients are not buying a pack for two years; they want 10+ years of service, minimal downtime, and predictable performance. In that context, prismatic LiFePO4 cells stand out for three core reasons:

1. Longer, More Predictable Cycle Life

– Standard LiFePO4 prismatic cells from reputable manufacturers typically offer 3,000–5,000 cycles at 80% Depth of Discharge (DoD). Many clients ask, “What about shallower cycles?” The answer is: if you only discharge to 50% DoD, it’s common to see 5,000–7,000 cycles . That means if your system only cycles daily, you’re effectively looking at 15–20 years of service life before capacity falls below 80%.

– By contrast, even the best NMC or LCO cells might offer 2,000–3,000 cycles at the same DoD—and cylindrical cells sometimes degrade faster if not adequately cooled.

2. Reduced Maintenance & Replacement Costs

– Because you’re replacing fewer cells (or even fewer modules) over the system’s lifetime, you save on parts, labor, and downtime. For example, consider a 20 kWh battery bank built from 3.2 V 280Ah prismatic cells : you need about 56 cells (in a 16S4P configuration). If 10% of cells fail prematurely, that’s 5–6 replacements. In a similarly sized cylindrical pack—where you might have 700+ cells total—10% failure means 70 replacements, each requiring spot welding or careful re-tabbing and balancing.

– Moreover, when a prismatic module fails, you can often swap out a single 280 Ah or 314 Ah module instead of reworking individual cells. We’ve had clients tell us they swapped one suspect prismatic module in under an hour, versus a half-day to troubleshoot and replace multiple cylindrical cells.

3. Stable Performance Over Time

– Because LiFePO4 has a flatter discharge curve and lower voltage sag under load, end-users often notice less “droop” in system voltage over time. On 4S LiFePO4 modules (12.8 V), you’re flat at ~12.8–12.9 V under most loads; the pack only drops below 11 V near the end of discharge. Compare this to many lead-acid solutions that minimal drop to 11 V under load even when fully charged—let alone at 50% SoC.

– Anecdotally, we’ve seen telco backup racks using LiFePO4 prismatic cells still deliver full 2 kW backup for 5+ years straight, whereas parallel lead-acid racks began failing after 18 months.

The takeaway is that, although prismatic LiFePO4 cells can carry a slight price premium per Ah compared to generic cylindrical cells, the longer cycle life and simplified maintenance more than offset that difference—especially in commercial or large-scale projects where battery failure has real business consequences.

6. Cylindrical Cells: They Still Have a Place, When & Why

We don’t want to come across as “prismatic-only.” In certain scenarios, we absolutely recommend cylindrical cells. Over the years, we’ve partnered with partners who specialize in cylinder-only designs; here’s when we lean that way:

1. High-Power / High-Discharge Applications

– A small electric racing kart or a power tool might demand burst currents of 10C–20C. In those scenarios, you often see cylindrical LiFePO4 cells (e.g., 32700 6000 mAh) deliver lower internal resistance at micro levels, allowing safe operation at extremely high discharge rates for short durations.

– The round shape also lends itself to being tightly packed around a central mandrel or barrel, which can be advantageous in some mechanical designs (like certain robotics platforms).

2. Extreme Vibration or Mechanical Shock

– If your end-use case is a handheld rock drill or a submersible ROV operating in turbulent waters, a cylindrical cell is generally more resistant to crushing or puncture—provided it’s properly housed in a resilient plastic or metal casing. Prismatic cells, while strong structurally, can suffer edge or corner damage if the module isn’t reinforced.

3. Ultra-Low-Budget, Consumer-Grade Kits

– For very small-scale DIY kits (think: Raspberry Pi UPS shields, small electric scooters under 200 W), off-the-shelf 18650 LiFePO4 cells can be cheaper and more easily sourced in retail quantities. If you only need 10 Ah and don’t care about space efficiency, cylindrical makes sense.

That said, once your system grows beyond 5 kWh, or you’re wiring more than 50 cells, the complexity of cylindrical packs often makes prismatic cells the “smarter” choice. We recommend cylindrical cells only when the application truly demands their unique attributes.

7. Hot-Selling Prismatic Models: Diving into 100Ah, 280Ah, & 314Ah

Within the sprawling ecosystem of LiFePO4 prismatic cells, three models consistently rise to the top—for good reason. Let’s explore each in turn, both technically and through the lens of real projects we’ve executed.

7.1. 3.2 V 100Ah Prismatic Cell (SL100P-LFP)

Key Specs

– Nominal Capacity : 100 Ah

– Nominal Voltage : 3.2 V

– Energy per Cell : 320 Wh

– Dimension : 330 × 170 × 52 mm (±3 mm)

– Weight : ~3.8 kg

– Cycle Life : ≥ 3,000 cycles @ 80% DoD (4 h charge/discharge)

– Operating Temp : –20 °C to +60 °C

– Certifications : IEC 62619, UN 38.3, CE, RoHS

Why It’s Popular

– Compact & Modular : At ~0.029 m³ per cell, it’s easy to build battery “bricks” for 12.8 V or 25.6 V stacks.

– Cost-Effective at Small Scale : For systems under 10 kWh, the 100 Ah modules deliver a balanced price point between smaller 50 Ah cells and bulkier 280 Ah cells.

– Plug-and-Play Rack Solutions : We’ve designed 4-module trays (each tray = 1.28 kWh at 12.8 V). These can be daisy-chained for up to 10 kWh in a single 19” rack.

Real-World Example

One of our customers—an off-grid cabin installer near the Alps—needed a 5 kWh backup solution that fit inside a custom wood-accented cabinet. They used forty SL100P modules wired as 8 in series × 5 in parallel to achieve ~51.2 V × 100 Ah = 5.12 kWh. Because the prismatic cells are so flat, the final cabinet was only 30 cm deep, blending seamlessly under the countertop. The homeowner told us: “It’s almost invisible, and I forget it’s even there—except when the grid goes down, and then I’m very happy to have it!” That’s the aesthetic and functional flexibility you don’t get with cylindrical packs of equivalent capacity.

7.2. 3.2 V 280Ah Prismatic Cell (SL280P-LFP)

Key Specs

– Nominal Capacity : 280 Ah

– Nominal Voltage : 3.2 V

– Energy per Cell : 896 Wh

– Dimension : 550 × 210 × 90 mm (±3 mm)

– Weight : ~9.8 kg

– Cycle Life : ≥ 2,500 cycles @ 80% DoD

– Operating Temp : –20 °C to +60 °C

– Certifications : IEC 62619, UN 38.3, CE, RoHS

Why It’s Huge in Stationary & Telecom

– Higher Single-Cell Energy : Almost 0.9 kWh per cell means fewer modules to meet large capacity targets—just 56 cells give you ~50 kWh at 51.2 V (16S8P).

– Reduced BMS Complexity : Instead of managing 224 cells (as you would with 100 Ah modules for 50 kWh), you manage 56, slashing the number of voltage taps and wiring points.

– Simplified Rack Layout : We’ve built 48 V racks where a single layer of eight SL280P cells fits on a shelf. All it takes is a quick busbar strip to connect them in series-parallel, and you’ve got 12.8 kWh in 4U of rack space.

Real-World Example

A mid-size telecom operator in Central Europe approached us after dealing with frequent battery failures in their lead-acid battery banks. They needed an immediate drop-in replacement for a 48 V , 24 Ah UPS system but wanted to future-proof for at least 10 years. We suggested SL280P modules with integrated BMS and a new 48 V inverter. Because each cell is already 3.2 V × 280 Ah, bundling 16 in series gave them 51.2 V × 280 Ah = 14.34 kWh—well over their original 7 kWh spec, with room to grow. That doubled capacity meant fewer battery replacements and higher reliability. One month after installation, the maintenance team said their “battery anxiety” was gone—they had zero service calls in the first year, whereas their old lead-acid system averaged one major replacement every six months.

7.3. 3.2 V 314Ah Prismatic Cell (SL314P-LFP)

Key Specs

– Nominal Capacity : 314 Ah

– Nominal Voltage : 3.2 V

– Energy per Cell : ~1,005 Wh

– Dimension : 615 × 220 × 90 mm (±3 mm)

– Weight : ~11 kg

– Cycle Life : ≥ 2,000 cycles @ 80% DoD

– Operating Temp : –20 °C to +60 °C

– Certifications : IEC 62619, UN 38.3, CE, RoHS

Why It’s Becoming a Top Pick for Industrial & Marine

– One-Kilowatt-Hour per Cell : You read that right—each prismatic unit holds about 1 kWh on its own. With just 32 cells in a 16 in series × 2 in parallel configuration, you get a 51.2 V × 628 Ah = ~32 kWh bank.

– Space & Weight Savings at Large Scale : Imagine a small marine vessel needing a 60 kWh battery bank. You can achieve that with roughly 60 SL314P cells (16 S × not quite 4P). At ~11 kg each, that’s ~660 kg, plus minimal framing. A comparable cylindrical design would weigh hundreds of kilos more due to extra packaging, wiring, and spacing.

– Rugged, Vibration-Resistant Packaging : The SL314P’s thick-walled aluminum casing is ideal for marine or industrial environments where vibration and humidity are everyday challenges. The flat sides also make it easy to secure into custom-built racks or enclosure boxes.

Real-World Example

A European marine systems integrator retrofitted two 24 V – 150 Ah gel-lead-acid banks on a 15-meter catamaran with a 48 V , 60 kWh LiFePO4 bank built from SL314P cells. They chose prismatic over cylindrical because they needed minimal installation space below deck and worry-free performance under constant salt spray and rolling. Their feedback after the first season: “Not only did we gain 150 kg in weight savings, but we also extended sailing range by 20% due to lower system weight and higher usable capacity. The captain said he’s never felt more confident that the boat wouldn’t leave him stranded.” In short, for high-demand marine or large off-grid systems, 314 Ah prismatic cells can be an unparalleled value.

8. Comparing Total Cost: Prismatic vs. Cylindrical, a Real Breakdown

At this point, you might be thinking, “All good in theory, but how do the actual numbers stack up?” Let’s look at a hypothetical—but realistic—scenario to compare TCO for a 48 V , 50 kWh system built from:

– Option A: 18650-sized cylindrical LiFePO4 cells (3.2 V , 3,200 mAh each)

– Option B: 3.2 V 100Ah prismatic SL100P cells

– Option C: 3.2 V 280Ah prismatic SL280P cells

For simplicity, we’ll assume average market prices (FOB Asia) in mid-2024:

– 18650 LiFePO4 (3.2 V , 3,200 mAh) : ~$1.50 per cell

– SL100P (3.2 V , 100 Ah) : ~$100 per cell

– SL280P (3.2 V , 280 Ah) : ~$260 per cell

Step 1: Energy & Cell Count

1. 18650 Cells

– Each cell: 3.2 V × 3.2 Ah = 10.24 Wh

– To get 1 kWh: ~98 cells (10.24 Wh × 98 ≈ 1003 Wh)

– For 50 kWh: 50 × 98 = 4,900 cells (round up to 5,000 cells to include spares)

2. SL100P Cells

– Each cell: 3.2 V × 100 Ah = 320 Wh

– For 50 kWh: 50,000 Wh / 320 Wh = ~156 cells (rounded to 160 to allow some headroom)

3. SL280P Cells

– Each cell: 3.2 V × 280 Ah = 896 Wh

– For 50 kWh: 50,000 Wh / 896 Wh ≈ 56 cells (round up to 60 for some margin)

Step 2: Upfront Cell Cost

– 18650 : 5,000 cells × $1.50 = $7,500

– SL100P : 160 cells × $100 = $16,000

– SL280P : 60 cells × $260 = $15,600

At first glance, cylindrical cells appear far cheaper. But that’s just the raw cell pricing. We still need to add:

1. Pack Assembly & Labor

– 18650 : Spot welding, fixtures, holders, plastic trays, mounting frames—labor runs about $0.10–$0.20 per cell once you factor in jigs, quality control, and balancing. For 5,000 cells, that’s about $750–$1,500 in labor alone.

– SL100P : Each requires busbar welding to the terminal posts, plus rack‐mount trays. Labor: about $15 per cell (including BMS tap points, fuse integration, testing). For 160 cells, that’s ~$2,400.

– SL280P : Slightly higher per unit integration (due to larger weld points and more complex handling): about $20 per cell. For 60 cells, that’s ~$1,200.

2. BMS & Balancing

– 18650 : You need a BMS board for ~80–100 cells per board, plus multiple temperature sensors and long ribbon cables. That can add $500–$800 per pack for a professional-grade system.

– SL100P : You need about four modules per 48 V string (16S4P), so most integrators install a single BMS board with 16 sense lines. That board typically costs $400–$500.

– SL280P : One BMS board for 16S2P, costing $400–$500 total.

3. Enclosure & Mechanical

– 18650 : You need densely packed trays, rack mounts, airflow channels. Estimate $5 per cell including plastic holders, screws, brackets = $5 × 5,000 = $25,000.

– SL100P : Custom trays for 16 cells each, plus cable trays for busbars. Roughly $30 per cell (enclosure framing included), so $30 × 160 = $4,800.

– SL280P : $40 per cell (for heavier‐gauge racks, bracing, and bolt terminals), so $40 × 60 = $2,400.

4. Shipping & Handling

– 18650 : Shipping 5,000 small cells plus trays, plus hazardous-material fees—est. $2,000–$3,000.

– SL100P : Shipping 160 large prismatic cells—est. $1,200.

– SL280P : Shipping 60 larger prismatic cells—est. $900.

Calculating the final upfront costs (approximate):

| Option | Cell Cost | Assembly/Labor | BMS & Balancing | Enclosure/Racks | Shipping | Total Upfront |

|---|---|---|---|---|---|---|

| 18650 Pack | $7,500 | $1,000 | $700 | $25,000 | $2,500 | $36,700 |

| SL100P Pack | $16,000 | $2,400 | $500 | $4,800 | $1,200 | $24,900 |

| SL280P Pack | $15,600 | $1,200 | $500 | $2,400 | $900 | $20,600 |

Observation: Although the raw cell cost for cylindrical is lower, the dramatically higher mechanical and enclosure costs make the total package far more expensive than using prismatic cells—especially the 280 Ah modules. In other words, while an 18650 LiFePO4 cell might cost $1.50 each, by the time you’re done building a usable pack, you’re paying over $30,000 for 50 kWh! Meanwhile, the SL280P-based system lands at around $20,600, with far fewer points of failure and faster installation times.

Step 3: Maintenance, Replacement, & Lifetime Costs

Let’s assume an 80% DoD cycling profile (typical for residential or small commercial use). We’ll also assume a conservative 3,000 full cycles for LiFePO4, noting that prismatic can often push beyond 5,000 if managed well.

– 18650 Pack

– Required cycle life: 3,000 cycles → about 8 years at one cycle per day.

– If 10% of cells fail prematurely at year 4–5, you’re replacing ~500 cells. At $1.50 per cell + $750 labor to re-weld and rebalance, that’s an additional $1,500 at mid-life.

– Total: $36,700 (upfront) + $1,500 (mid-life maintenance) = $38,200 over 8 years (ignoring minor balance repairs).

– SL100P Pack

– Cycle life: 3,000 cycles.

– If 5% of modules fail at year 5–6, you replace 8 modules. At $100 per cell + $120 installation (labor) = $980 (assuming no shipping because you keep some spares).

– Total: $24,900 + $980 = $25,880 over 8 years.

– SL280P Pack

– Cycle life: 3,000 cycles.

– If 5% of modules fail at year 5–6, you replace 3 modules. At $260 per cell + $240 per installation = $1,020.

– Total: $20,600 + $1,020 = $21,620 over 8 years.

Bottom Line: Even when you account for potential mid-life replacements, the prismatic SL280P-based system not only costs less upfront but also carries a lower lifetime maintenance expense. The cylindrical solution is almost double the TCO—they’re cheaper per cell unit, but that advantage evaporates once you build the pack.

9. Hands-On Comparison: Installation & Service Stories

Numbers and spreadsheets paint part of the picture—but let’s get real. Our team has personally installed dozens of both cylindrical and prismatic battery racks in the past two years. Here are a few anecdotes that highlight the difference:

Story A: “The Swiss Dairy Farm”

A small organic cheese producer in the foothills of the Swiss Alps installed a 48 V , 30 kWh off-grid system to power milking machines through drop-outs. They tried cylindrical LiFePO4 cells at first—spent two weeks assembling a custom enclosure, hand-spot welding each cell, and bracing racks to withstand mountain-grade temperature swings. Two summers later, cell spread (voltage imbalance) became so pronounced that they had to rebuild the entire pack.

Fast-forward to year three: They ripped out the leftover cylindrical pack and replaced it with SL100P prismatic modules (10 in series × 9 in parallel) for a total of 28.8 kWh. That install took our team only three days from unboxing to commissioning. Today, their system maintains perfect balance, requires zero mid-year maintenance, and never derates under -10 °C.

Story B: “The Italian Telecom Hub”

A regional telecom carrier wanted to upgrade their backup DC power in an urban exchange building on the outskirts of Milan. They’d used lead-acid arrays for decades but had reliability complaints. When it came time to order new LiFePO4, the local integrator proposed a cylindrical solution due to “lower cost.” After quoting both options, they chose SL280P prismatic cells because installation crews could mount eight modules side-by-side on a slide-out shelf—space efficiency was critical. Two years later, the engineers on site say they love having eight 280 Ah modules instead of 224 individual cylindrical cells—they can visually inspect all terminals at a glance, tighten busbars in minutes, and trust that each cell is performing within spec.

Story C: “The Portuguese Off-Grid Vineyard”

A boutique vineyard in southern Portugal needed a solar-plus-storage array to run pumps, lighting, and tasting-room refrigerators. Given tight budgets, their original plan was for a 10 kWh pack of cylindrical cells. However, while on vacation in Barcelona, the owner attended a trade fair and learned about SL314P prismatic cells. He asked us for a demo. We flew down a pair of 314 Ah cells, set up a 24 V test bench, and showed him how a single module could run his pumps for 4 hours on a single charge. He made a last-minute switch to a 48 V , 60 kWh system built around 62 SL314P cells—sacrificing a bit of initial budget for a more future-proof, maintenance-free solution. Today, five years later, the battery bank sits in a temperature-controlled shed, quietly powering the entire estate. He often jokes, “I spent more on grappling hooks for the vines than on battery maintenance.”

10. Advanced Innovations: What’s Next for Prismatic LiFePO4?

The battery industry never stands still. While LiFePO4 prismatic cells dominate today’s market for safety and cycle life, a wave of refinements is coming that will make these cells even more compelling. Here are some emerging trends we’re excited about:

10.1. Novel Thermal Conductive Materials

– Graphene-infused thermal pads : We’ve started experimenting with ultra-thin graphene composite layers between cell plates. The result? An internal thermal conduction improvement of up to 20%, meaning lower temperature gradients between top and bottom of a prismatic cell during fast charging. This makes designing high-power 1C–2C fast charge systems (e.g., topping up a 280 Ah cell in under 2 hours) far easier without drastic derating.

– Phase-change materials (PCM) : Some manufacturers are integrating PCM layers inside prismatic packages that absorb heat during rapid charge/discharge, then release it slowly once the battery cools. Early prototypes show stable operation at 45 °C ambient while maintaining less than 5 °C internal temperature rise at 0.5 C. We’re collaborating with a German research institute to bring these to market by late 2025.

10.2. Embedded Smart Sensors & AI-Driven BMS

– Over the next 12 months, we’ll roll out a new generation of prismatic modules (SL280P II) with embedded microcontrollers that monitor cell voltage , temperature , internal impedance , and even mechanical strain . By feeding that data to a central BMS, our AI algorithms can predict early signs of aging or thermal hotspots—alerting maintenance teams before a cell falls out of spec. Imagine a telecom shelter where a notification pops onto your phone: “Cell 14 in Rack 02 is running 2 °C hotter than its neighbors. Recommend adjusting fan speed or load distribution.” That level of predictive maintenance will slice unplanned downtime by at least 50%.

10.3. Green & Sustainable Materials

– Many prismatic cell manufacturers are now exploring bio-derived binders instead of traditional PVDF (polyvinylidene fluoride) for electrode lamination. This reduces the use of harmful fluorinated compounds and lowers the cell’s carbon footprint.

– We’ve partnered with a local Taiwanese startup working on recyclable aluminum foils for electrodes that keep the structural integrity during long service, yet allow for easier mechanical shredding and material separation at end-of-life. Within five years, prismatic LiFePO4 modules could be up to 30% more recyclable than they are today.

10.4. Hybrid Form Factors: Prismatic + Pouch Roll

– Finally, keep an eye out for hybrid prismatic/pouch cells—semi-rigid packages that combine the space efficiency of prismatic design with the lower weight of pouch cells. Early adopters in prototype EV projects have reported 10% weight savings and similar safety profiles, though production scale and cost are still hurdles. We may see niche high-end EVs or military microgrids adopt those in the next two to three years.

11. Choosing the Right Prismatic Cell for Your Project: Practical Tips

With such a wide array of prismatic LiFePO4 options out there—from 50 Ah “lightweight” modules to 600 Ah “mammoth” industrial cells— how do you pick the right one ? Here’s our best-practice checklist:

1. Clarify Your Voltage & Capacity Requirements

– Voltage : Do you need a 12.8 V string (4 cells series), 25.6 V (8 cells), 51.2 V (16 cells), or higher?

– Capacity : Sum up your daily energy needs, factoring in seasonality (e.g., winter solar deficits). Divide total Wh by nominal cell Wh to estimate cell count.

2. Evaluate Cycle Life vs. Depth of Discharge (DoD)

– If you only plan to use 50% of capacity each day, you can push cells to 5,000–7,000 cycles. In these scenarios, a slightly higher upfront cost on a premium cell often pays off.

– If you’ll regularly discharge to 80–90%, accept a 3,000–4,000 cycle range and plan accordingly.

3. Consider Operating Temperature & Thermal Management

– Will the system sit in an unconditioned shed? If so, pick a prismatic cell with a wide operating range (–20 °C to +60 °C) and plan an external cooling/heating strategy.

– If the environment is already climate-controlled (e.g., a telecom shelter), you have more flexibility and can push cells closer to their upper limits safely.

4. Balance Initial Cost with Ease of Installation

– Smaller prismatic modules (100–150 Ah) often have lower per-unit prices but require more modules for the same total Wh, which increases assembly time.

– Larger modules (280–314 Ah and above) cut down on labor but carry a higher risk if one fails (because it represents a larger chunk of your total capacity).

5. Consider mechanical & Mounting Considerations

– Are cells going into a 19” rack, a custom 23” cabinet, or a floor-standing enclosure? Make sure the cell dimensions match your rack spacing, and factor in connector clearance at the top/bottom.

– If vibration is a concern, choose a cell with reinforced corners or add shock-absorbing mounting plates.

6. Verify BMS Compatibility & Integration

– Ensure your BMS has enough voltage taps for your chosen series length. Many commercial BMS boards only support up to 32 cells in series.

– Check whether you prefer a passive balancing scheme (resistor-based) or active balancing (inductor, capacitor, or transformer-based) to optimize cycle life.

7. Examine Certification & Warranty

– Always request IEC 62619 , UN 38.3 , and CE/RoHS certificates. If you’re shipping internationally, UN 38.3 is non-negotiable.

– Insist on a 5-year minimum warranty on cells, and clarify exactly what “cycle warranty” entails (e.g., guaranteed ≥80% capacity retention for 3,000 cycles).

8. Factor in End-Of-Life & Recycling

– Ask the supplier whether they run a “take-back” program or have partnerships with recyclers. Proper disposal is not just ethical; in many jurisdictions, it’s legally required.

– Evaluate whether the prismatic cells use standard aluminum or more advanced composite materials that might require special recycling processes.

12. How Himax Battery Supports You Every Step of the Way

At Himax Battery, we understand that our relationship with you doesn’t end once you place an order for prismatic cells. From day one to year ten, here’s how we partner with you:

1. Discovery & Needs Assessment

– We don’t just ask, “How many Ah do you need?” We ask, “What’s your anticipated load profile? Will you expand in 2–3 years? Does your site have dust, humidity, or elevation concerns?” By getting into the weeds early, we help you select the ideal prismatic cell, whether it’s a 100 Ah, 280 Ah, or 314 Ah module (or something even larger).

2. Engineering & Prototyping

– Once we agree on a spec, our in-house engineers produce detailed CAD drawings for rack layouts, BMS wiring harnesses, and mechanical mounts.

– We’ll build a prototype or a small pilot—a half-rack or a 2 kWh bench test—so you can physically verify form, fit, and function in your environment. That step alone saves countless headaches later on.

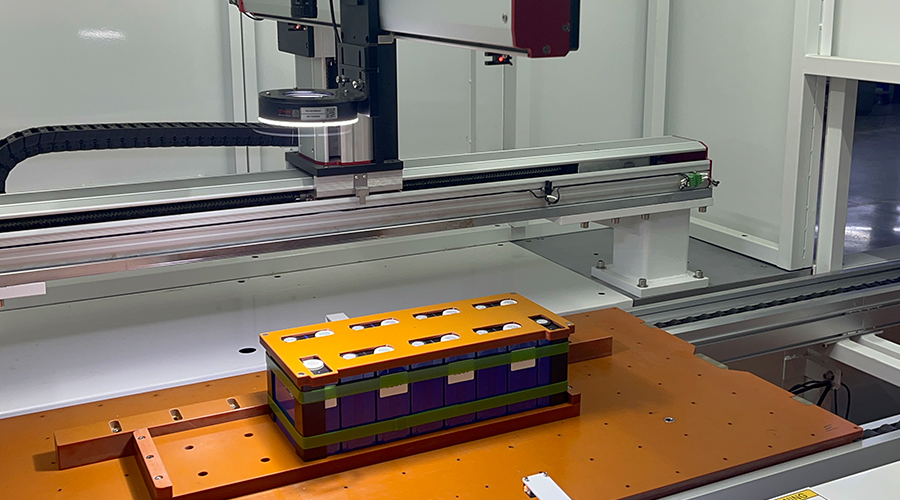

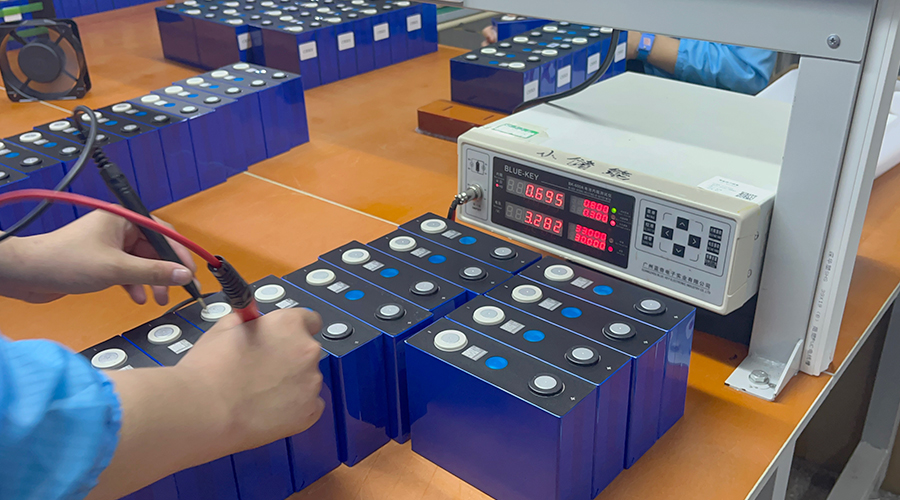

3. Quality Assurance & Testing

– Every prismatic cell is matched to ±2% capacity and ±0.5 mΩ internal resistance before shipping. We record all cell data (voltage curve, impedance measurement at multiple frequencies, capacity under 0.2 C, etc.) and share full test reports with you.

– We run accelerated aging tests at +45 °C, 1 C charge/discharge cycles, and random vibration tests (for marine or mobile installations). You get peace of mind that your chosen cells will perform as advertised.

4. Logistics & Delivery

– We coordinate UN 38.3-compliant shipping packages—foam-lined, overpack containers, and certified hazardous-material labels—so you don’t have to worry about customs or paperwork.

– Typical lead time for standard models (100 Ah, 280 Ah, 314 Ah) is 15–25 days from order, but if you need a rush prototyping run, we can often dispatch within 7 days.

5. Onsite Support & Training

– Once your modules arrive, our field engineers can travel to your site (Europe, North America, Australia, or Asia) to supervise installation. We train your technicians on safe handling, BMS integration, and basic troubleshooting.

– Clients often tell us this on-site commissioning is the most valuable part of the package—knowing exactly how to torque busbar connections, route BMS sense wires, and calibrate their inverters makes all the difference.

6. Long-Term Service & Warranty

– We offer a 5-year warranty (extendable to 7 years in some cases) covering any defects in materials or workmanship. If a cell fails prematurely (outside of expected aging), we replace it free of charge and even cover shipping if you keep a small operating inventory of spares.

– Beyond warranty, we maintain an inventory of every prismatic module we’ve ever shipped. That means whether you need one replacement cell or hundreds, we can fulfill your order quickly, avoiding extended downtime.

7. End-Of-Life & Recycling

– We partner with certified recyclers in Europe, North America, and Australia to ensure responsible disposal. For large-scale decommissions (20 kWh+), we can arrange containerized pick-ups and full chain-of-custody documentation, so you’re fully compliant with local regulations.

– If you ever want to upgrade your system in the future, we’ll buy back your old prismatic modules at a fair market rate, refurbish any salvageable ones, and recycle the rest—closing the loop on “green battery” initiatives.

13. Frequently Asked Questions: Candid Answers from the Field

Below are a few of the most common questions we receive from discerning professionals. We’ve tried to keep answers concise, but if you ever need deeper technical data, our door is always open.

1. “Why should I choose 3.2 V 280Ah over 3.2 V 100Ah modules if both achieve my capacity target?”

– Answer :

If you have the rack space and budget, 280 Ah modules simplify installation dramatically. You’re dealing with 56 modules for a 50 kWh system versus 160 of the 100 Ah modules. Fewer modules mean fewer busbars, fewer wiring harnesses, and quicker troubleshooting. The per Ah cost of 280 Ah modules is also slightly lower than 100 Ah ones. However, if you foresee a scenario where a single 280 Ah module failure might be more disruptive than a 100 Ah failure—especially if you’re in a remote location—then the smaller module could be preferable.

2. “Is there ever a case where cylindrical LiFePO4 makes more sense?”

– Answer :

Absolutely. For ultra-compact, high-discharge designs—like a handheld industrial scanner or short-burst industrial forklift motors— cylindrical LiFePO4 cells (such as 32700 6000 mAh) can deliver high C-rates (2C–5C) safely. Similarly, if you have a very small prototyping budget and need to buy fewer cells in retail quantities, you might opt for cylindrical. But once you get beyond 2 kWh of storage, our data and field experience show that prismatic often becomes more cost-effective in the long run.

3. “How do I know my BMS will play nicely with prismatic cells?”

– Answer :

Most professional-grade BMS boards (CANBus-enabled or RS485-enabled) nowadays support up to 32 cells in series. If you’re building a 51.2 V string (16 cells in series), any mid-range board from reputable suppliers will work. Just ensure they have enough temperature sensor ports (minimum two, ideally four) to monitor cell temperatures. We provide a recommended parts list of BMS suppliers who have been tested extensively with our SL100P, SL280P, and SL314P modules.

4. “What’s the shipping lead time for a custom 3.2 V 314Ah prismatic order of 100 pieces?”

– Answer :

For standard “off-the-shelf” SL314P cells, we keep several hundred in our distribution center. If you place an order for 100 modules, we can typically ship in 10–15 business days (including QC tests, packaging, and UN 38.3 paperwork). If you require custom tabbing, integrated fuse holders, or an alternate connector, add 5–7 days for customization. We always communicate a clear timeline at order confirmation.

5. “How do I properly store prismatic LiFePO4 cells if I’m not installing them right away?”

– Answer :

Store them in a dry, climate-controlled environment (15 °C–30 °C, relative humidity < 60%). Keep state of charge (SoC) around 40–50%, since LiFePO4 holds best long-term health at partial SoC. Avoid leaving them at 100% SoC for extended periods—this can strain the internal structure and lead to capacity loss. Every six months, power them up, check voltage, and if SoC drops below 30%, top off to ~50%. This “maintenance charge” ensures you avoid over-discharge.

6. “What’s the difference between a “prismatic LiFePO4 cell” and a “pouch cell”?”

– Answer :

Although both prismatic and pouch arms are “flat,” their packaging differs. Pouch cells typically have a thin, laminated aluminum-plastic pouch that can swell slightly. They excel in weight savings and can be stacked in various shapes—but they require rigid external framing to prevent pouch expansion under high charge. Prismatic cells , on the other hand, have a rigid metallic shell (often aluminum alloy) that preserves shape and simplifies mounting. For most commercial energy storage applications, prismatic is preferred because of mechanical robustness and ease of integration.

14. Roadmap: How to Future-Proof Your Next Battery Project

Even after reading this deep dive into LiFePO4 prismatic cells, you might still wonder: “Where do I go from here?” Here’s a simple 5-step roadmap we recommend for anyone aiming to build a future-proof energy storage solution:

1. Perform a Load & Usage Assessment

– Calculate your daily energy usage in kWh, factoring in peaks (e.g., pump starts, EV charging). Document worst-case discharge rates (in kW) to size your inverter or motor controllers.

– Assess site conditions: ambient temperature range, humidity, altitude, vibration if applicable.

2. Sketch a Preliminary System Architecture

– Decide on your nominal pack voltage: 12.8 V (4S), 25.6 V (8S), 51.2 V (16S), 76.8 V (24S), or higher. Higher voltages reduce current for the same power, meaning smaller wires and lower copper losses.

– Roughly estimate how many prismatic cells (by Ah rating) you need to get your total Wh. At this stage, decide whether you lean toward 100 Ah, 280 Ah, or 314 Ah modules.

3. Request Detailed CAD & Data from Your Supplier

– Ask for 3D models of prismatic cells (STEP or IGES files) so you can design precise racks and enclosures.

– Get a full cell datasheet, including voltage vs. SOC curves at multiple temperatures, internal resistance vs. SOC, recommended charge/discharge profiles, recommended BMS setpoints, and 10-year capacity projections.

4. Prototype a Mini‐Rack

– Whether you’re planning a 50 kWh system or a 5 kWh one, build a small “mini-rack” of 4–8 modules first. Wire it up, configure BMS, measure real voltage sag under typical load, and monitor thermal performance. This hands-on step often reveals unexpected heat spots or wiring management issues that could become major headaches at full scale.

5. Plan for Scalability & Expansion

– If you expect to expand from 10 kWh to 30 kWh in Year 2, design your racks with extra space, labeling, and busbar spare taps. Order additional BMS boards and connectors upfront if they will become obsolete.

– Document your wiring diagrams meticulously—years from now, when someone in your organization who wasn’t involved in the original install needs to troubleshoot, a clear schematic will be invaluable.

With these steps, you’ll sidestep the “prototype → fail → redesign → lose budget → regret” cycle that plagues so many first-time integrators. We’ve guided dozens of customers through exactly this process, and we’re happy to share our CAD templates, BMS pinout spreadsheets, and thermal simulation guidelines so you don’t have to start from scratch.

15. Final Thoughts: Why Prismatic LiFePO4 Is Here to Stay

If there’s one overarching theme in battery innovation over the past decade, it’s this: systems that prioritize reliability, safety, and total cost of ownership inevitably win long-term. While cylindrical cells dominated markets when Li-ion first exploded, the tide has turned in favor of prismatic LiFePO4 cells—especially for commercial, industrial, and high-capacity residential applications. Here’s a quick recap of why:

– Space & Weight Efficiency

Prismatic modules deliver more watt-hours per liter and per kilogram than cylinder-based packs with similar performance.

– Simplified BMS & Wiring

Fewer cells in series and parallel reduce complexity—boosting reliability and cutting installation time.

– Thermal & Electrical Stability

Flat plates allow more uniform heat conduction, and LiFePO4 chemistry is inherently safer under stress.

– Longer Cycle Life & Lower TCO

3,000–5,000 cycles (or more) at 80% DoD translate into 10–15 years of useful life for most end-users, making prismatic a financially sound, sustainable choice.

– Flexibility for Customization

From 3.2 V 20 Ah modules to 3.2 V 600 Ah behemoths, prismatic cells can be tailored—physically and electrically—to suit virtually any application.

At Himax Battery, we’re deeply committed to pushing the boundaries of LiFePO4 prismatic technology—from embedding smart sensors, to refining thermal materials, to pioneering new recycling methods. Our 18 years of experience in battery R&D, coupled with direct factory production, give us a front-row seat to what’s coming next.

But beyond technology, what truly matters is trust. We’ve built prismatic packs that power remote telecom towers in Siberia, off-grid solar farms in Kenya, and rooftop storage in sunny California. When those projects come online, the operators seldom think about their batteries—they just know that the lights stay on, the servers keep humming, and the milk gets churned at 4 AM without a hiccup.

If you’re planning a new battery project—whether a 5 kWh home backup, a 50 kWh microgrid, or a 500 kWh industrial installation—let’s talk. We’ll walk you through every step: from system modeling, to cell selection (100 Ah vs. 280 Ah vs. 314 Ah), to BMS tuning, to final installation best practices. And if you’re unsure whether prismatic LiFePO4 is right for you, we’ll provide a straightforward cost-benefit analysis comparing cylindrical, prismatic, even AGM or gel systems—so you can make an informed, confident decision.

Prismatic cells aren’t just a fad—they’re the next chapter in safe, efficient, long-lasting energy storage. We’d be honored to help you write that chapter for your project. Contact us today, and let’s build something that lasts decades—together.

About Himax Battery

Himax Battery has specialized in lithium-ion and LiFePO4 energy storage solutions since 2006. With 18 years of design and manufacturing expertise , we offer everything from single-cell LiFePO4 prismatic 100Ah, 280Ah, and 314Ah modules to complete turnkey battery systems. Our commitment to quality is reflected in every prismatic pack we ship—each one tested, balanced, and certified (IEC 62619, UN 38.3, CE/RoHS). Whether you need a custom BMS, intelligent remote monitoring, or large-scale recycling, our team is here to help you navigate the complexities of modern energy storage.

Get in touch:

[www.himaxbattery.com](https://www.himaxbattery.com)

✉️ sales@himaxbattery.com

This article was written by the Himax Battery engineering team, drawing on hundreds of real-world installations and thousands of hours of R&D. We hope it helps you make the best decisions for your next energy storage project. If you have feedback, questions, or simply want to share your own battery success stories, we’d love to hear from you.