As the golf cart industry continues to evolve in 2025, more and more owners are making the switch from traditional lead-acid batteries to advanced 48V lithium systems. Compared to their heavier and lower-efficiency predecessors, modern lithium batteries offer greater cycle life, lighter weight, faster charging, and simplified maintenance. Whether you’re a golf course operator seeking to reduce operating costs, a recreational user aiming for longer rides between charges, or a fleet manager responsible for multiple vehicles, this guide will walk you through why 48V lithium batteries are now the gold standard—and how to choose and install one properly.

In this post, we will cover:

1. Why replace your 48V lead-acid golf cart battery with lithium

2. Key criteria for selecting the right 48V lithium battery

3. Comparisons of leading brands (including the new Himassi 48V 100Ah model)

4. Step-by-step installation instructions

5. Best practices for daily use and maintenance

6. Cost-benefit analysis and return on investment (ROI) calculations

7. Final recommendations and future outlook

By the end of this guide, you’ll understand how to evaluate different 48V lithium options, appreciate the features and benefits of the Himassi 48V 100Ah Golf Cart Battery, and feel confident installing and maintaining your new power source.

1. Why Choose 48V Lithium Over Lead-Acid

1.1 Cycle Life Comparison

Traditional lead-acid golf cart batteries typically deliver between 300–500 full discharge cycles before capacity drops below 80%. In contrast, high-quality lithium iron phosphate (LiFePO₄) batteries routinely achieve 2,000–3,000 cycles under normal operating conditions. Over multiple years of use, this translates to dramatically lower replacement frequency—and therefore lower overall cost of ownership.

– Lead-acid: ~300–500 cycles

– Lithium (LiFePO₄): ~2,000–3,000 cycles

Given that many golf carts are cycled daily, especially in commercial or resort settings, switching to lithium can stretch a battery’s usable life from roughly 1–2 years up to 5–8 years.

1.2 Weight, Space, and Energy Density

Lithium cells, by design, offer significantly higher energy density. A typical 48V 100Ah LiFePO₄ pack weighs 60–80 lbs, whereas an equivalent lead-acid bank can exceed 200 lbs. The reduced weight not only improves cart performance—accelerating faster and climbing hills with less strain—but also liberates additional payload capacity (passengers or cargo).

Furthermore, lithium modules tend to be more compact, allowing for a cleaner fit in existing battery compartments without modification. By shaving off over 100 lbs, you reduce stress on the suspension and drivetrain, which can extend the life of other mechanical components.

1.3 Charging Efficiency and Faster Turnaround

Lithium batteries can accept higher charge currents and maintain a higher voltage plateau during most of their charge cycle. This means:

– Faster charging: A 48V 100Ah LiFePO₄ pack can often be charged from 20% to 80% in just 2–3 hours (with a compatible 48V-specific charger).

– Near-flat discharge curve: Throughout most of the discharge cycle, lithium maintains close to 48V, whereas lead-acid voltage drops more significantly as it discharges. This translates to more consistent speed and torque for longer periods.

As a result, golf courses or operators with limited downtime between rounds can quickly recharge carts during brief breaks, keeping them in service for more hours each day.

1.4 Environmental Impact and Ease of Maintenance

Unlike lead-acid chemistry—which involves sulfuric acid, potential off-gassing, and periodic watering—LiFePO₄ cells are inherently non-toxic, do not emit hazardous fumes, and require virtually zero maintenance:

– No watering needed: Lead-acid cells must be refilled with distilled water periodically to avoid plate damage. Lithium requires no topping off.

– No sulfation risk: Lead-acid batteries are prone to sulfation if left partially charged; lithium chemistry is not affected, so you can store them at any state of charge without damage.

– Recyclable: LiFePO₄ cells are recyclable and contain no heavy metals such as lead.

In terms of day-to-day upkeep, simply keeping the terminals clean and ensuring the BMS is functioning properly is all that’s required. There’s no risk of acid leaks or corrosion that typically plague lead-acid installations.

2. Key Factors When Selecting a 48V Lithium Golf Cart Battery

Investing in a 48V lithium battery is not a trivial decision. To ensure you get the right pack for your cart and usage pattern, consider these six essential factors:

2.1 Capacity (Ah) and Required Range

Your daily range requirements will drive capacity selection. In most golf cart applications, a 100Ah battery can deliver 8–10 miles of driving under mixed loads (flat terrain, occasional modest incline, two riders). If you operate in a hilly area or carry heavy loads, you might need to step up to 120–150 Ah.

1. Estimate daily mileage: Observe your typical usage—rounds played, terrain difficulty, passenger weight, and speed.

2. Allow buffer: It’s wise to not routinely discharge below 20% State of Charge (SOC) to extend battery life. If you need a true 10-mile daily range, consider a 120 Ah pack rather than a 100 Ah.

3. Charging opportunities: If curbside chargers are available at intervals during the day, you might get away with a 100 Ah pack. Without mid-day charging, err on the side of higher capacity.

2.2 Chemistry and Cell Type

While multiple chemistries exist, LiFePO₄ (Lithium Iron Phosphate) stands out for golf cart applications:

– Thermal stability: Less prone to thermal runaway compared to certain cobalt-based chemistries (e.g., NMC).

– Long cycle life: Up to 3,000 cycles at 80% Depth of Discharge (DoD).

– Safety: Resilient to overcharge, overdischarge, and short-circuit events when paired with a quality BMS.

Some manufacturers still market Li-ion NMC (Nickel Manganese Cobalt) or other variants, claiming higher energy density. However, for the rigors of golf cart use—constant vibration, temperature fluctuations, and heavy discharge currents—LiFePO₄ remains the recommended choice.

2.3 Battery Management System (BMS) Capabilities

A robust BMS is the “brain” of any lithium battery. Key BMS features to look for:

– Overcharge/overdischarge protection: Prevents cells from exceeding safe voltage thresholds (usually 3.65 V per cell for LiFePO₄).

– Short-circuit and overcurrent protection: Shuts down output in the event of an accidental short or excessive draw.

– Cell balancing: Ensures all cells remain at equal voltage over repeated charge cycles.

– Temperature monitoring: Shuts down the pack if extreme temperatures are detected (below 0 °C or above 65 °C).

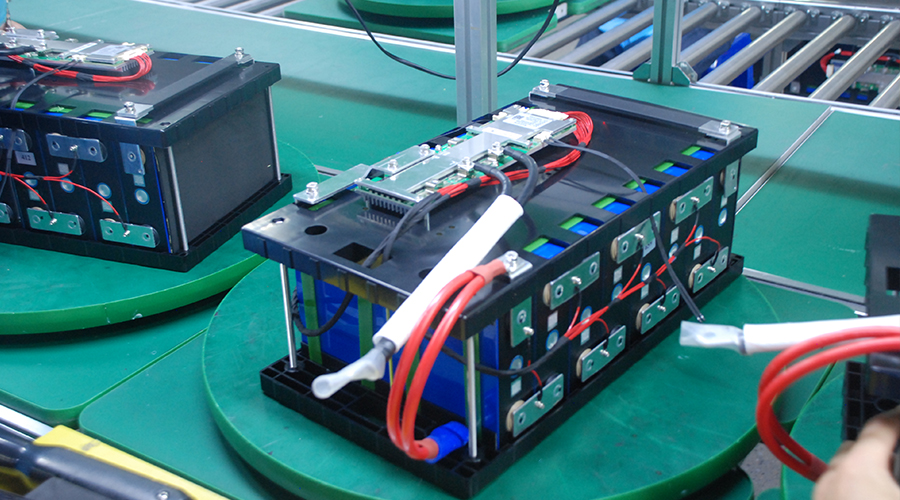

– Communication port: Some BMS units include CAN-bus, RS485, or Bluetooth modules for real-time monitoring.

Without these safeguards, individual cells may become imbalanced, overheat, or fail prematurely. Always confirm the manufacturer’s BMS rating (continuous and peak current tolerance) aligns with your golf cart’s drivetrain and controller demands.

2.4 Brand Reputation and After-Sales Support

A high-quality battery from a reputable manufacturer backed by solid warranty terms can save headaches down the road. When evaluating brands:

1. Warranty duration: Look for at least a 3–5 year limited warranty covering capacity fade below a specified threshold (often 60–70%).

2. Customer service: Access to technical support via phone, email, or chat can be crucial—especially during initial setup or troubleshooting.

3. Authorized dealers: An official distribution network ensures genuine products and consistent pricing.

4. Customer reviews: Seek out unbiased user feedback on performance, failure rates, and timely service.

Featured Model — Himassi 48V 100Ah Golf Cart Battery

– Bluetooth Connectivity: Built-in Bluetooth module allows real-time monitoring of voltage, current, and SOC via a free smartphone app.

– Smart Display: Integrated LED screen on the battery housing shows State of Charge (%), cycle count, and fault warnings at a glance.

– 48V Dedicated Charger: Included high-efficiency charger rated specifically for 48V LiFePO₄ chemistry, featuring auto-cutoff when fully charged.

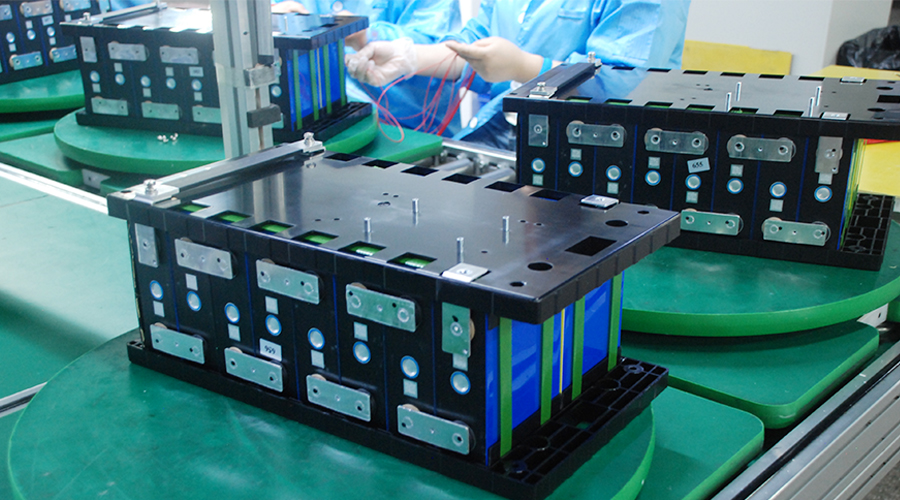

– Upgraded Internal Structure: Premium 32700 LiFePO₄ cells arranged in a 16S configuration with enhanced cell holders, thicker copper busbars, and reinforced welding to improve reliability.

– Integrated Bracket Design: Custom one-piece steel mounting frame welded to the battery enclosure, ensuring superior vibration resistance and simplified installation.

The Himassi pack’s combination of smart features, safety upgrades, and solid mechanical design place it among the leading 48V solutions for both commercial and residential users.

2.5 Physical Dimensions, Mounting, and Compatibility

Before placing an order, verify:

– Battery compartment dimensions: Measure the length, width, and height of your existing tray.

– Terminal orientation: Ensure the positive (+) and negative (–) posts align with your cart’s wiring.

– Weight clearance: Although lithium is lighter, confirm the battery’s overall footprint and mounting holes match factory specifications or that bracket adaptors are supplied.

– IP Rating (Ingress Protection): Ideally IP65 or higher to guard against water sprays and dust—especially if your course uses aggressive power-washing routines.

The Himassi 48V 100Ah, for example, is designed to fit most E-Z-GO, Club Car, and Yamaha models produced after 2005. Its welded bracket features adjustable bolt patterns to accommodate slight variations in tray size without drilling new holes.

2.6 Price and Value Assessment

While lithium batteries carry a higher upfront cost—often 2–3× that of a comparable lead-acid bank—their extended cycle life, reduced maintenance, and energy savings quickly offset the premium. When calculating:

1. Initial battery cost + charger

2. Installation labor (if you’re not installing it yourself)

3. Projected cycle count (e.g., 2,500 cycles for LiFePO₄ vs. 400 for lead-acid)

4. Electricity consumed per cycle (lithium is typically 95% efficient; lead-acid around 80%)

5. Residual value (some providers offer trade-in credits on old lead-acid banks)

In most commercial or high-usage scenarios, the break-even point falls between 2–4 years, after which the lithium investment clearly outperforms any ongoing lead-acid refresh costs.

3. Market Comparison: Leading 48V Lithium Brands and Models

Below is a simplified comparison of popular 48V lithium golf cart battery options. Specifications and pricing can vary, so always verify with the manufacturer or authorized dealer.

Brand and Model Comparison

| Brand / Model | Capacity (Ah) | Battery Chemistry | BMS Features | Warranty | Approx. Price (USD) | Standout Features |

|---|---|---|---|---|---|---|

| Lifeline 48V 100Ah LiFePO₄ | 100 | LiFePO₄ | Over/Under Voltage, Temp. Protection, Balancing | 4 years | $2,500 – $2,700 | Known for robust cells, proven reliability |

| Trojan ICL-48V 155Ah LiFePO₄ | 155 | LiFePO₄ | Integrated Balancer, High-Temp Cutoff | 5 years | $3,900 – $4,200 | Extra capacity for extended range, rugged aluminum housing |

| Precision 48V 115Ah LiFePO₄ | 115 | LiFePO₄ | Bluetooth Monitoring, Overcurrent Protection | 3 years | $3,100 – $3,300 | Mobile app support, modular design for easy expansion |

| Himassi 48V 100Ah Golf Cart | 100 | LiFePO₄ (32700) | Over/Under Voltage, Temp. Protection, Balancing, Bluetooth | 4 years | $2,600 – $2,800 | Smart Display, Bluetooth, 48V Charger, Upgraded Internal Structure, Integrated Bracket |

| Renogy 48V 100Ah LiFePO₄ | 100 | LiFePO₄ | Overcharge, Overdischarge, Short-circuit Protection | 3 years | $2,400 – $2,600 | Affordable, widely available online, good BMS |

| Battle Born 48V 100Ah LiFePO₄ | 100 | LiFePO₄ | Balancing, Thermal Protection, Customizable Profiles | 5 years | $2,700 – $2,900 | Lightweight, modular “stackable” housing, popular in off-grid communities |

Why Himassi Stands Out:

The Himassi 48V 100Ah pack matches or exceeds many competitors in terms of cycle life and safety, while adding conveniences like built-in Bluetooth, an intuitive smart display, and a custom 48V charger optimized for LiFePO₄ chemistry. Its welded, one-piece bracket system eliminates the need for aftermarket mounting solutions, saving installers time and reducing potential rattle or vibration issues. Any golf cart owner seeking a plug-and-play, reliable upgrade will appreciate how seamlessly the Himassi unit integrates into existing carts.

4. Installation Steps for a 48V Lithium Golf Cart Battery

Replacing a lead-acid battery with a lithium pack requires careful attention to detail. Follow these steps to ensure a safe, trouble-free installation.

4.1 Preparation

1. Gather Tools and Safety Gear

– Socket set or adjustable wrenches (typically 3/8″, 7/16″, or ½″ depending on your cart’s connector size)

– Insulated screwdrivers or nut drivers

– Safety glasses and insulated gloves

– Multimeter or digital voltmeter

– Clean rags and a mild, non-acidic cleaner (to wipe terminal surfaces)

2. Power Down and Remove Lead-Acid Battery

– Park the cart on level ground, set the parking brake, and remove the key.

– Lift the seat or battery box cover to access the batteries.

– Using your insulated wrench, disconnect the negative (–) terminal(s) first on the lead-acid side. Then disconnect all positive (+) terminals. Keep cables away from battery posts to prevent accidental reconnection.

– Remove any hold-down clamps, brackets, or tie-downs securing the lead-acid bank. Carefully slide or lift out each heavy battery, placing them on a sturdy, acid-resistant surface.

3. Inspect and Clean Battery Tray

– Look for traces of acid residue. If present, neutralize with a baking soda solution (1 tablespoon per quart of water), rinse, and dry thoroughly.

– Verify the tray dimensions and terminal spacing match your new lithium pack. If the Himassi bracket doesn’t line up exactly, check for optional adapter plates or consult a local golf cart technician for minor tray modifications.

4.2 Installing the Himassi 48V 100Ah Battery

1. Position the Battery with Integrated Bracket

– Gently slide the Himassi unit into the tray. The integrated steel bracket should align with the four existing bolt holes (two on each side). If your cart uses different patterns (e.g., older Club Car or custom tray), use the included bracket shims to adapt.

– Secure the bracket with the supplied M8 × 25 mm stainless bolts and nuts. Tighten each bolt gradually, alternating sides to ensure even pressure—finger-tight plus an additional quarter turn should suffice. Do not overtighten; you don’t want to deform the bracket.

2. Connect Wiring and Terminals

– Identify the positive (+) and negative (–) battery bus bars on the Himassi pack. These will be clearly labeled.

– First, reconnect the positive (+) cable from the golf cart’s controller to the battery’s positive post. Use a torque wrench to tighten to manufacturer-specified values (usually around 10–12 lb-ft), ensuring a snug, vibration-resistant connection.

– Next, reconnect the negative (–) cable to the battery’s negative post in the same manner.

– Make sure any auxiliary wiring (for accessories or additional BMS connections) is routed neatly and does not pinch under the bracket or chassis.

3. Attach the Dedicated 48V Charger

– Plug the included 48V LiFePO₄ charger into the wall outlet first. Confirm the charger LED is indicating standby or ready.

– Connect the charger’s output cable to the pack’s charger port (often an Anderson SS-50 or similar heavy-duty connector). The Himassi charger is programmed to deliver up to 14.4 V × 16 series cells at 10 A maximum, then taper to trickle charge before auto-cutoff.

– After plugging in, the charger will run through its startup diagnostics. Observe the charger’s LED or LCD readout. It should show “24 V Boost” (for half-charged) or “Charging” if below 90% SOC. Leave it connected until it indicates “Full” or “Green,” typically 2–3 hours from a 20% SOC state.

4. Initial System Check and Calibration

– Before lifting the cart off the charger, use a multimeter to spot-check the pack voltage. A fully charged 16-cell LiFePO₄ pack should be 16 × 3.65 V = 58.4 V (sometimes reported as 57.6 V if the BMS caps at 3.60 V per cell).

– Power on the golf cart controller. Observe the speed controller’s LED or LCD for any error codes (e.g., “Low Voltage Cutoff” or “Controller Fault”). If you see any immediate fault, power everything down and re-inspect connections.

– Use the Himassi mobile app (iOS/Android) to pair via Bluetooth. Confirm it displays pack voltage, individual cell voltages, temperature, and cycle count. If the app reports any cell imbalance greater than 0.05 V, allow the battery to sit idle for 30 minutes; the BMS will automatically balance.

– Once the BMS indicates balanced cells (all within 0.01 V), take the cart for a short test drive (50–100 feet) at low speed to confirm the drivetrain is functioning. Return to inspect connections again—tighten if necessary.

4.3 Post-Installation Testing

1. Load Test Under Light to Moderate Conditions

– On level ground with two passengers, drive the cart along a ¼-mile loop. Monitor any irregularities in acceleration or sudden voltage drops on the smart display.

– Check the Himassi display for real-time discharge current. Long sustained draws above the BMS’s 100 A continuous rating may trigger protective cut-off. If you need higher amperage, consider a larger Ah pack or parallel configurations (consult the manufacturer).

2. Verify Charger Disconnect

– Sometimes, chargers remain powered even when the pack is full. Confirm the Himassi charger LED turns green (or “Charged”) and its display reads 58.4 V. Unplug from mains, then from the battery pack.

– After removing the charger, power on the cart again and verify no lingering charger signals interfere with the controller. If you see a “Charger Detected” warning on the controller, double-check that the charger cable is fully disengaged from the battery.

3. Check BMS Alarms During Operation

– During the first 24 hours of regular use, periodically glance at the Himassi display. Any fault codes (e.g., “OV” for overvoltage, “UV” for undervoltage, “OC” for overcurrent) warrant immediate inspection.

– If an overcurrent fault presents under normal conditions, you may need to install a higher-rated fuse on the main positive line (consult a certified technician).

5. Daily Use and Maintenance Best Practices

Once your new 48V lithium battery is in service, these guidelines will help you maximize life and performance.

5.1 Recommended Operating Habits

– Keep top-off charges regular: While LiFePO₄ tolerates partial charges, consistent shallow discharges (15%–80%) are ideal. Avoid letting the pack drop below 20% SOC frequently.

– Use Bluetooth monitoring: Check cell voltages and pack health weekly through the Himassi app. Early detection of cell imbalance can prevent long-term degradation.

– Avoid extreme temperatures: LiFePO₄ cells perform best between 0 °C and 45 °C. In winter climates where temperatures dip below freezing, store carts in a heated garage or use an external battery blanket.

– Charge after each use: Lithium can be stored at any SOC without harm, but a full charge before extended storage (over two weeks) helps maintain the BMS calibration and prolong life.

5.2 Periodic Inspections

– Terminal Tightness: Once a month, check that the positive and negative terminals are torqued correctly (10–12 lb-ft).

– Bracket & Tray Condition: Inspect welded edges and mounting bolts for corrosion, cracks, or loosening.

– Cables & Harnesses: Look for frayed insulation, corrosion at lugs, or any signs of arcing. Replace cables approaching end-of-life.

– Smart Display & Bluetooth Module: Ensure firmware is up to date—Himassi periodically releases updates to improve BMS algorithms, fix bugs, and provide new monitoring features.

5.3 Charger and Accessory Care

– Charger Ventilation: Keep the 48V LiFePO₄ charger in a well-ventilated, dry area while in operation. Avoid stacking other equipment on top of it.

– Cable Management: Coil cords neatly, and never sharply bend the charger cable—over time, this can damage inner wiring.

– Firmware Updates: Occasionally, the Himassi charger’s microprocessor firmware may be updated. Check the manufacturer’s website or contact support every 6 months to ensure you’re using the latest version.

5.4 Troubleshooting Common Issues

1. Low Voltage Alarm During Operation

– Possible causes: Unbalanced cells, BMS malfunction, or genuine deep discharge.

– Actions: Park the cart, switch off all loads, and let it rest for 10 minutes. Use the Himassi app to check cell voltages. If one cell reads >0.05 V below its neighbors, allow the BMS to balance or perform a “Balance Charge” (connect charger with balance mode enabled).

2. Charger Won’t Start or Complete Cycle

– Possible causes: Faulty charger cable, poor connection, or BMS preventing charge due to gate driver lock-out.

– Actions: Inspect connectors for dust or corrosion. Ensure the charger sees pack voltage above its minimum threshold (usually ~10 V per string). If the pack is extremely low (below 40 V), you may need a “boost” from a compatible charger or perform a slow trickle.

3. Excessive Heat During Discharge

– Possible causes: Overcurrent, poor ventilation, or damaged BMS.

– Actions: Confirm that the cart’s controller is not demanding more than the pack’s rated continuous discharge. Ventilate the battery box (drilling small drainage holes can help). If the issue persists, power down the cart and consult Himassi support—there may be an internal short or cell issue.

6. Cost-Benefit Analysis & Return on Investment

Understanding the financial implications of switching to a 48V lithium battery can justify the upfront cost. Below is a sample comparison between a $2,600 Himassi 48V 100Ah LiFePO₄ pack and a typical $900 lead-acid (six-6V, 225 Ah each) battery bank.

6.1 Assumptions

– Usage: Golf cart operates 20 days/month, 10 miles/day, average discharge of 80%.

– Lead-acid: 400 cycles at 80% DoD before replacement.

– LiFePO₄: 2,500 cycles at 80% DoD before capacity falls below 80%.

– Electricity Cost: $0.13/kWh (U.S. average).

– Energy Efficiency: Lead-acid 80%, LiFePO₄ 95%.

– Maintenance: Lead-acid requires $50/year for watering, cleaning, and occasional cell replacement; LiFePO₄ maintenance is negligible.

– Installation Labor: $200 for either system (assumes a trained technician).

6.2 Lead-Acid Cost Calculation (5-Year Period)

1. Initial Purchase:

– Battery bank (6 × 6V at $150 each) = $900

– Charger (48V lead-acid compatible) = $200

– Installation labor = $200

– Total upfront: $1,300

2. Replacement Cycles in 5 Years:

– Lead-acid lifespan: ~400 cycles → ~20 months of daily use (assuming one cycle per day).

– In 5 years (60 months), you would need 2.5 sets of lead-acid banks.

– Replacement cost: 1.5 additional banks × $900 = $1,350 (charger and labor likely reused).

3. Electricity Costs:

– Each full cycle uses roughly 48 V × 225 Ah = 10.8 kWh.

– At 80% efficiency, input energy = 10.8 kWh / 0.80 = 13.5 kWh.

– Daily cost: 13.5 kWh × $0.13 = $1.76.

– Over 5 years (e.g., 20 days × 12 months × 5 years = 1,200 cycles): 1,200 × $1.76 = $2,112.

4. Maintenance Costs:

– $50/year × 5 years = $250.

5. Total 5-Year Cost (Lead-Acid):

– Upfront & replacements: $1,300 + $1,350 = $2,650

– Electricity: $2,112

– Maintenance: $250

– Grand Total: $5,012

6.3 LiFePO₄ (Himassi) Cost Calculation (5-Year Period)

1. Initial Purchase:

– Himassi 48V 100Ah LiFePO₄ pack = $2,600

– Dedicated 48V LiFePO₄ Charger (included) = $0†

– Installation labor = $200

– Total upfront: $2,800

2. Replacement Cycles in 5 Years:

– LiFePO₄ lifespan: ~2,500 cycles → ~7 years of daily use (one cycle per day).

– Within 5 years, no replacement needed.

3. Electricity Costs:

– Each full cycle uses 48 V × 100 Ah = 4.8 kWh.

– At 95% efficiency, input energy = 4.8 kWh / 0.95 = 5.05 kWh.

– Daily cost: 5.05 kWh × $0.13 = $0.66.

– Over 5 years (1,200 cycles): 1,200 × $0.66 = $792.

4. Maintenance Costs:

– Minimal; assume $0 (no watering, negligible cleaning).

5. Total 5-Year Cost (LiFePO₄):

– Upfront: $2,800

– Electricity: $792

– Maintenance: $0

– Grand Total: $3,592

Comparison:

– Lead-Acid (5 years): $5,012

– LiFePO₄ (5 years): $3,592

– Savings over 5 years: $1,420

Even if you factor in a modest $100 for periodic BMS checkups or app-based firmware updates, the lithium solution still yields a net savings of well over $1,300 in just five years. After the fifth year, your LiFePO₄ pack continues delivering reliable service—whereas the lead-acid system would have required a third set of batteries.

7. Conclusion and Recommendations

7.1 Why Upgrade to 48V Lithium in 2025

– Extended Lifespan: Up to 3,000+ cycles versus 400–500 for lead-acid.

– Lower Total Cost of Ownership: Less frequent replacements, better efficiency, and near-zero maintenance.

– Enhanced Performance: Consistent voltage under load, significant weight reduction, and faster charge times.

– Environmental Benefits: No toxic acid, recyclable LiFePO₄ cells, and a smaller carbon footprint over the battery’s life.

7.2 The Case for Himassi 48V 100Ah Golf Cart Battery

The Himassi pack is engineered from the ground up for golf cart applications:

– Bluetooth Connectivity & Smart Display: Real-time insights at your fingertips—no guessing about cell health or remaining runtime.

– Dedicated 48V Charger: Ensures the chemistry is charged correctly, maximizing cycle life and preventing overcharge.

– Upgraded Internal Structure: Premium 32700 cells arranged and welded in a robust chassis for thermal stability and vibration resistance.

– Integrated Bracket: Simplifies installation, virtually eliminating fitment adjustments and rattle-related failures.

With a 4-year warranty and proactive firmware support, Himassi caters to both commercial fleets and individual owners who refuse to compromise on reliability or convenience.

7.3 Final Tips for a Smooth Transition

1. Confirm Compatibility First: Even though most modern carts fit standard 48V LiFePO₄ packs, always double-check your tray dimensions and terminal orientation.

2. Plan for Professional Installation if Uncertain: While DIY is feasible for many, a certified golf cart technician can guarantee correct BMS integration and controller configuration.

3. Monitor and Maintain Consistently: Use the Himassi app every 1–2 weeks to spot cell imbalances or firmware updates. A 10-minute visual inspection of cables and the bracket will ward off rattles and loose connections.

4. Store Sensibly: During off-season periods or prolonged inactivity, store your cart at 40–60% SOC in a cool, dry environment. Periodically check cell voltages and recharge to 60% if any single cell dips below 3.2 V.

5. Stay Informed on Future Tech: Solid-state batteries and next-gen fast-charging chemistries are on the horizon, but as of 2025, LiFePO₄ remains the most cost-effective, reliable choice for golf carts.

By following this comprehensive guide—selecting a quality 48V LiFePO₄ pack like the Himassi 100Ah, installing it correctly, and adhering to best practices for use and maintenance—you will enjoy many years of dependable, efficient golf cart operation. The days of heavy lead-acid banks and tedious upkeep are behind us; the future is lightweight, smart, and sustainable.

Appendix (Optional)

Glossary of Terms

– SOC (State of Charge): The current capacity of the battery expressed as a percentage of its full capacity.

– DoD (Depth of Discharge): The percentage of the battery’s total capacity that has been used. For example, if you use 50 Ah out of 100 Ah, that’s a 50% DoD.

– BMS (Battery Management System): An electronic system that manages cell balancing, monitors temperature, and protects against overcharge/overdischarge.

– C-rate: A measure of the rate at which a battery is charged or discharged relative to its capacity. For example, 1C on a 100 Ah battery means charging/discharging at 100 A.

Frequently Asked Questions (FAQ)

1. Can I mix lead-acid and lithium batteries on the same cart?

– No. Mixing chemistries causes unpredictable voltage behavior and can damage both the battery and controller. Replace the entire bank with 48V lithium modules.

2. What happens if I let a LiFePO₄ pack sit at 0% SOC?

– Modern BMS modules will disconnect the pack to prevent overdischarge. However, prolonged low voltage may stress the cells. Always recharge to at least 20% SOC within 7 days.

3. Is a 48V lithium battery charger interchangeable between brands?

– Not always. Lithium chargers must match the specific voltage termination setpoints of the cell chemistry. Use the charger supplied by the manufacturer or a reputable aftermarket unit explicitly rated for 16 × 3.65 V LiFePO₄ cells.