1. Choosing the Right Battery for Your Application

As industries continue to demand high-performance, reliable, and energy-dense power solutions, choosing the right battery technology is crucial. Lithium-ion (Li-ion) and Lithium-Polymer (LiPo) batteries are two of the most widely used rechargeable battery types today, each offering distinct advantages.

For OEMs, bulk buyers, and industrial users, selecting between Li-ion cylindrical (18650, 21700), prismatic, or pouch-style LiPo batteries depends on factors like energy density, cycle life, form factor, cost-efficiency, and safety. This guide will help you determine which battery chemistry best suits your industry-specific needs.

2. Understanding Lithium-Ion Batteries

What Are Lithium-Ion Batteries?

Lithium-ion batteries are rechargeable cells that use a liquid electrolyte to transport lithium ions between the anode (graphite) and cathode (various lithium compounds such as NMC, LFP, or LCO). The most common formats include:

- 18650 Cylindrical Cells – Used in power tools, EVs, and UPS systems.

- 21700 Cylindrical Cells – Higher capacity and power output for industrial and automotive applications.

- Prismatic Cells – Compact and high-energy for EVs and energy storage.

Advantages of Li-ion Batteries

- Higher Energy Density: 250-300 Wh/kg, making them ideal for longer runtime applications.

- Longer Cycle Life: Up to 1000-3000 cycles, reducing the frequency of replacements.

- Cost Efficiency: More cost-effective in bulk production compared to LiPo batteries.

- Stable Performance: Well-regulated voltage and discharge rates.

- BMS Integration: Built-in Battery Management Systems (BMS) enhance safety and efficiency.

Common Industrial Applications

- Electric Vehicles (EVs) and Hybrid EVs

- Uninterruptible Power Supplies (UPS) and Energy Storage Systems (ESS)

- Power Tools and Industrial Robotics

- Medical Equipment and Aerospace Electronics

4. Lithium-Ion vs. Lithium-Polymer: Which One is Best for Your Industry?

| Feature | Lithium-Ion (Li-ion) | Lithium-Polymer (LiPo) |

| Energy Density | 250-300 Wh/kg | 150-200 Wh/kg |

| Cycle Life | 1000-3000 cycles | 300-1000 cycles |

| Safety | More stable, with BMS protection | Higher risk of swelling if overcharged |

| Shape & Flexibility | Fixed formats (cylindrical, prismatic) | Ultra-flexible pouch design |

| Cost Efficiency | Lower cost for large-scale production | Higher due to complex manufacturing |

| Typical Use Cases | EVs, industrial tools, energy storage | Drones, RC models, slim consumer devices |

Key Takeaways:

- If energy density, cost-effectiveness, and longevity matter most → Choose Li-ion.

- If size flexibility, lightweight design, or high discharge rates are critical → Choose LiPo.

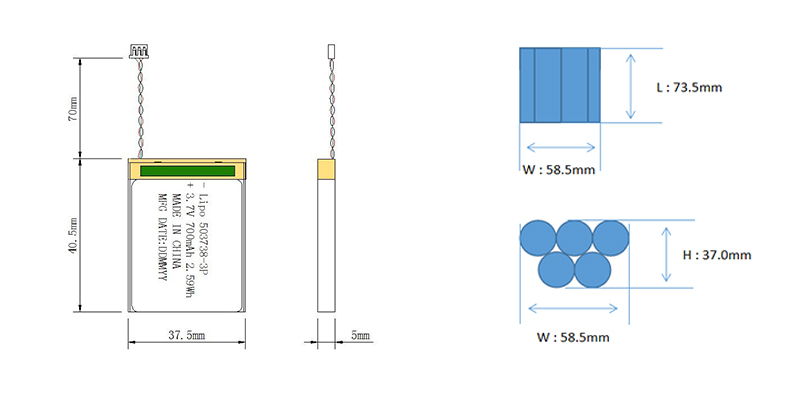

3. Understanding Lithium-Polymer Batteries

What Are Lithium-Polymer (LiPo) Batteries?

LiPo batteries use a solid polymer or gel-like electrolyte instead of liquid, allowing for a flexible, pouch-style design. These batteries are typically found in consumer electronics, drones, and other space-constrained applications.

Advantages of LiPo Batteries

- Ultra-Lightweight & Thin Form Factor: Ideal for compact and slim device designs.

- High Discharge Rates: Supports applications requiring high bursts of power.

- Flexible Design: Customizable shapes and sizes for niche applications.

Common Industrial Applications

- Drones, UAVs, and RC Models

- Wearable Devices and IoT Gadgets

- Medical Monitoring Equipment

- High-Performance Consumer Electronics

5. When to Choose Lithium-Ion for Your Business

- Best for industrial-scale applications that require high capacity and long lifespan.

- Recommended for OEMs needing standard cylindrical or prismatic cells.

- Ideal for bulk procurement buyers looking for cost-effective, reliable battery solutions.

- Perfect for energy storage, UPS systems, and EV battery packs.

6. When to Choose Lithium-Polymer for Your Business

- Best for space-constrained, lightweight applications where shape flexibility is crucial.

- Recommended for industries prioritizing design flexibility and power bursts.

- Great for applications requiring thin, customizable, high-discharge batteries, such as UAVs, drones, and smart devices.

7. Himax Custom Battery Solutions for Bulk Buyers

Himax specializes in providing custom Lithium-Ion and Lithium-Polymer battery solutions for industrial clients, ensuring:

- Tailored battery pack design to meet specific voltage, capacity, and form factor requirements.

- High-performance 18650, 21700, and LiPo pouch cells for bulk procurement.

- Advanced BMS integration for enhanced safety and efficiency.

- Certifications including CE, RoHS, UN38.3, IEC62619 to meet global compliance standards.

- Fast bulk delivery and after-sales technical support for business clients worldwide.

8. Making the Right Choice for Your Industry

- Choose Lithium-Ion if you need higher energy density, cost efficiency, and longer lifespan.

Choose Lithium-Polymer if you need flexible form factors and lightweight batteries for compact applications.